一.Product Introduction

The JIS 10K Threaded Ball Valve is a compact, JIS-compliant flow control component designed for space-saving, easy installation in small-to-medium piping systems. Rated at 10K (≈1.0 MPa), it offers material options (stainless steel 304/316, carbon steel, ductile iron) to suit general or corrosion-prone environments, with JIS-standard threaded connections that eliminate flange bolts/gaskets for fast assembly.

Equipped with a precision floating ball and high-performance seals (PTFE/EPDM), it ensures leak-tight shut-off, while full/reduced-bore designs adapt to different flow needs. Actuation choices (manual lever, gear, electric/pneumatic) fit manual or automated workflows, and it handles water, steam, oil, and weak chemicals at -20°C to 180°C. Ideal for industrial, municipal, and commercial HVAC systems, it balances reliability, interchangeability with JIS-aligned setups, and low maintenance.

二.Product Features

- Strict JIS Compliance: Manufactured to align with Japanese Industrial Standards, ensuring dimensional precision, seamless compatibility with JIS-aligned piping systems, and reliable interchangeability for global projects.

- Space-Saving Threaded Design: Features JIS-standard threaded connections, eliminating the need for flanges, gaskets, or bolts—enabling quick installation in tight spaces, ideal for small-to-medium piping networks.

- 10K Pressure & Wide Material Adaptability: Rated for 10K (≈1.0 MPa) pressure, with material options (304/316 stainless steel for corrosion resistance, carbon steel/ductile iron for general use) to match diverse environmental and media needs.

- Leak-Tight Performance: Equipped with a precision-machined floating ball and high-quality seals (PTFE for chemicals, EPDM for elasticity), ensuring secure shut-off even after frequent on-off cycles.

- Flexible Flow & Actuation: Offers full-bore (minimizes pressure drop) and reduced-bore (space-saving) port designs; actuation options include manual lever/gear, electric, or pneumatic to fit manual or automated workflows.

- Broad Application Versatility: Operates at -20°C to 180°C, compatible with water, steam, oil, and weak chemicals—suitable for industrial process lines, municipal utilities, and commercial HVAC systems.

三.Technical data

| Technical Parameter | Specification |

|---|---|

| Standard Compliance | JIS (e.g., JIS B2002 for pressure, JIS thread standards for connections) |

| Valve Type | Threaded Ball Valve |

| Pressure Class | 10K (equivalent to approx. 1.0 MPa) |

| Size Range | DN15 – DN100 (or custom per JIS specifications) |

| Body Material | Carbon Steel, Ductile Iron, Stainless Steel (304, 316) |

| Ball Material | Stainless Steel (304, 316), Carbon Steel |

| Seal Material | PTFE (polytetrafluoroethylene), EPDM (ethylene propylene diene monomer) |

| Temperature Range | -20°C to 180°C (varies by seal/body material combination) |

| Connection Type | Threaded (JIS-standard, e.g., PT/BSPT threads) |

| Port Design | Full-Bore, Reduced-Bore |

| Actuation Options | Manual (Lever, Gear), Electric, Pneumatic |

| Media Compatibility | Water, Steam, Mineral Oil, Neutral Fluids, Weakly Corrosive Chemicals |

| Operating Torque | Dependent on size and actuation type (provided by manufacturer per size) |

| Certifications | JIS, ISO, CE (varies by manufacturer) |

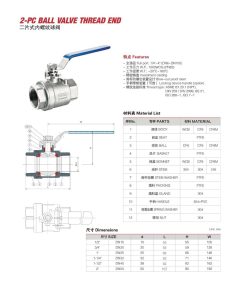

四.The main shape and connection size