I. Product Introduction

This pneumatic V-port ball valve adopts a cylindrical spring preloaded movable metal seat structure with compensation function, ensuring reliable sealing performance. The ball core and valve seat avoid jamming or separation, thus extending the service life. The V-shaped grooves on the ball core and metal seat have a shearing effect, making it particularly suitable for controlling media such as high-viscosity fluids, fiber-containing fluids, solid particles, and slurries. It performs exceptionally well in applications like pulp control in the papermaking industry.

As a type of ball valve, its closure component is a V-shaped notch on a hemisphere. The sharp edge of the V-shaped notch exerts a scraping effect between closure components during rotation, thereby providing strong cutting force on the medium. The V-shaped notch on the ball and the seat flow channel form a fan-shaped area, and the cross-sectional area of the flow channel can be changed during rotation to achieve precise regulation of the medium. It is an angular rotary control valve with the same sealing performance as ordinary ball valves, hence integrating both regulating and on-off functions. When paired with pneumatic or electric actuators, it is widely used in industrial process automation systems.

It is suitable for various fields including energy, petrochemical, metallurgy, chemical engineering, mining, papermaking, environmental protection, biochemistry, pharmaceuticals, electric power, printing and dyeing, light industry, food, tobacco, sugar making, and beverages.

II. Product Features

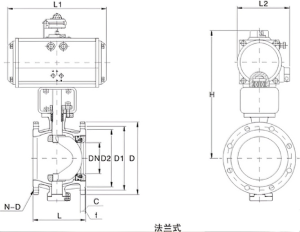

- Integral valve body structure: Both wafer-type and flange-type V-port ball valves adopt an integral side-mounted structure, featuring high structural rigidity, resistance to deformation, and no external leakage.

- Upper and lower self-lubricating bearings: The valve body is equipped with upper and lower self-lubricating bearings, which have a large contact area with the valve stem, high load-bearing capacity, and a small friction coefficient, reducing valve torque.

- Optional seat types: Depending on the medium and working conditions, the seat can be selected as metal hard-sealed or PTFE soft-sealed. The sealing surface of the metal hard-sealed seat is surfacing with hard alloy, and the spherical surface is hardened through processes such as hard chrome plating, spray welding, and ion nitriding, which improves the service life and temperature resistance of the sealing surface. The PTFE soft-sealed seat or reinforced PTFE seat has excellent sealing performance, corrosion resistance, and a wide range of applications.

- Economic efficiency and practicality: The valve body is lightweight with low stem torque, which also reduces the specification requirements for the supporting pneumatic or electric actuators. It offers a high cost-performance ratio compared with other types of control valves.

- Wide medium adaptability: Due to the shearing force between the V-shaped groove and the valve seat as well as the smooth and rounded flow channel in the valve cavity, the medium is not easy to accumulate in the valve cavity. Therefore, it is not only suitable for liquid media but also more suitable for system control of fiber-containing and solid particle-containing media.

- Precise control of small flow: Precise control of small Cv values can be achieved by machining special V-shaped grooves on small-diameter valve cores.

III. Technical Data

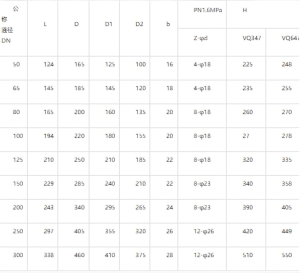

- Pressure Rating: PN16 (1.6MPa)

- Body Material: Carbon Steel (C)

- Seat Type: Metal Hard Seal (H)

- Actuation Method: Pneumatic

- Connection Method: Flange Connection

- Size Range: Various diameters are usually available to meet different pipeline requirements (specific dimensions shall be confirmed according to actual products)

- Temperature Range: Suitable for medium-temperature environments matching the characteristics of carbon steel and hard sealing materials (generally up to approximately 425℃, the specific value depends on detailed materials and design)

- Flow Characteristic: Linear or Equal Percentage (based on V-port design)

- Seat Leakage Class: Complies with relevant industry standards for metal hard-sealed valves (e.g., ANSI/FCI 70-2 Class IV or higher)

- Medium Compatibility: Suitable for high-viscosity fluids, fiber-containing, solid particle-containing, and slurry media, as well as general liquids and gases in industries such as energy, petrochemical, and papermaking.

- Standard Compliance: Manufactured and tested in accordance with relevant industrial valve standards to ensure performance and quality.

IV. Body Shape and Connection Dimensions