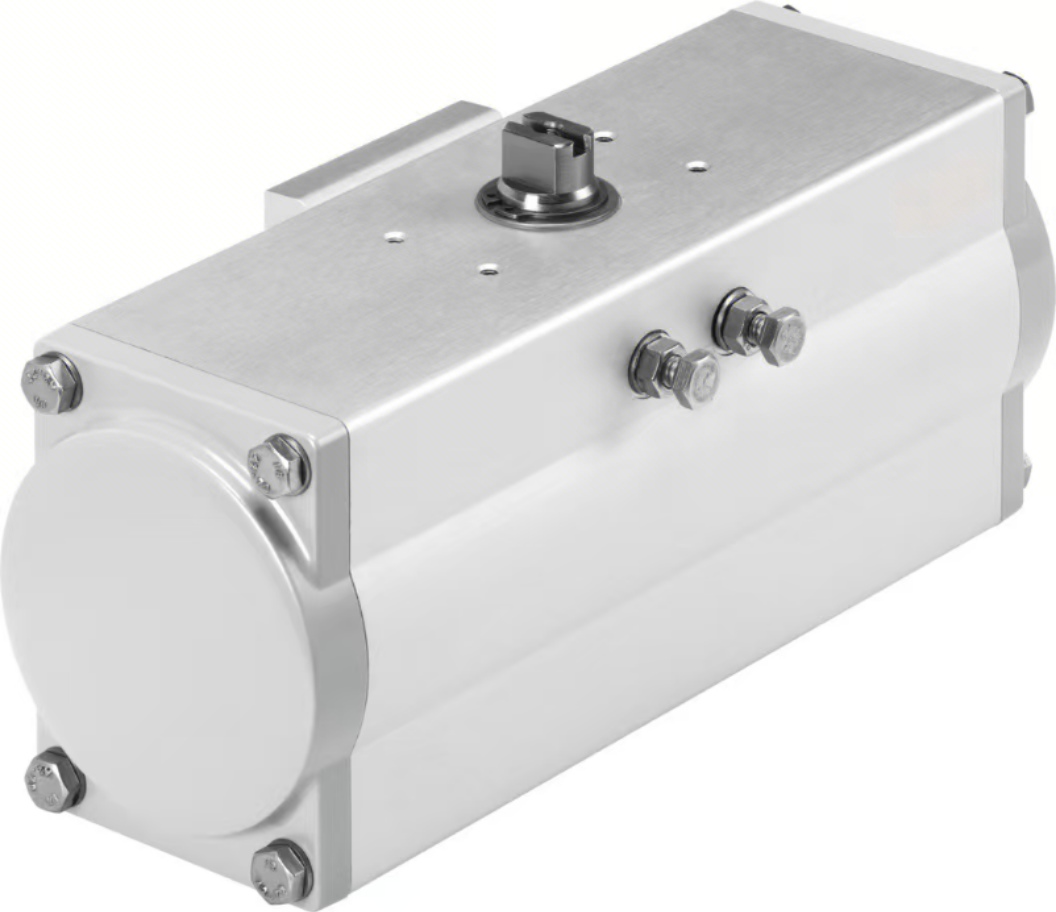

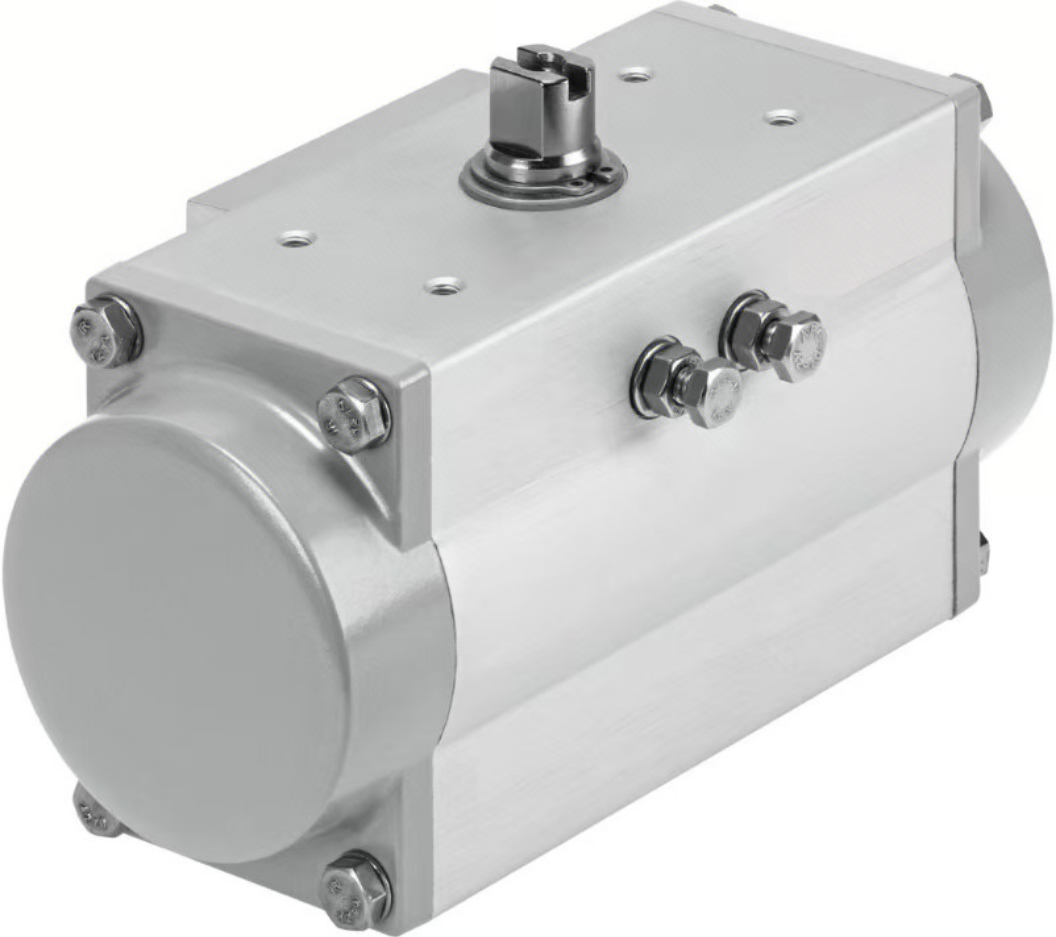

一、产品介绍

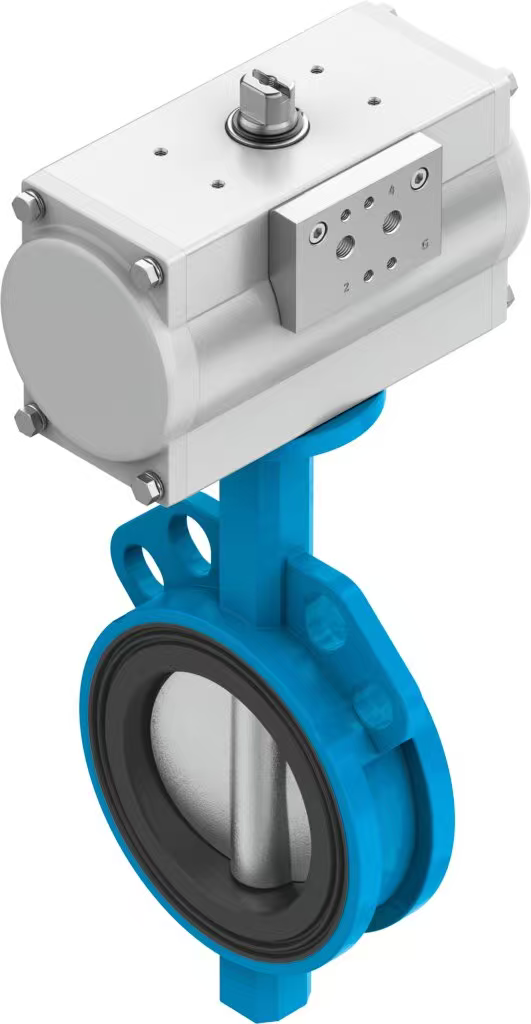

这款四分之一转执行器是由WYEValve公司生产的高性能四分之一转执行器,专为工业阀门控制应用中精确可靠的90度旋转运动而设计。它属于气动执行器,利用压缩空气产生扭矩来驱动四分之一转阀门,例如球阀、蝶阀和旋塞阀。凭借其坚固的结构和先进的设计,这款执行器可确保高效的阀门驱动,从而有助于在包括化工、石油化工、水处理和制造等在内的各种工业环境中实现平稳的工艺控制。

二、产品特点

-

精确的90度旋转角度该执行器提供精确的90度旋转角度,完美匹配四分之一圈阀门的全开/全关操作要求。这种精度消除了阀门错位,确保了性能的稳定性。

-

高扭矩输出在额定工作压力下,它可提供 20.1 Nm 的扭矩,即使在苛刻的工艺条件下也能提供足够的力来平稳地驱动阀门,从而提高运行可靠性。

-

坚固的气动连接配备 G1/8 气动连接,可实现安全无泄漏的空气供应,确保稳定的气动操作,并与标准工业管道系统兼容。

-

标准化法兰和轴设计

- F03 法兰孔型确保与各种阀门安装配置兼容,简化安装和集成。

- T9 轴连接可实现执行器和阀门之间安全、精确的扭矩传递,最大限度地减少反冲和磨损。

-

坚固耐用的结构:该执行器采用优质材料制造,具有出色的抗工业磨损、抗腐蚀和抗环境因素性能,确保较长的使用寿命和降低的维护成本。

-

高效的气动操作其气动驱动机构可实现快速响应时间,便于快速驱动阀门,以便及时进行工艺调整并提高操作效率。

三.技术数据

- 阀门执行器尺寸20

- 法兰孔型F03

- 旋转角度90 度

- 末端位置调节范围为 0° -5° … 5°

- 标称旋转角度下的末端位置调节范围为-5 度至 5 度

- 轴连接深度10 毫米

- 连接件符合ISO 5211标准

- 安装位置可选

- 工作方式:双作用

- 设计齿轮齿条

- 收盘方向:向右收盘

- 符号00991265

- 阀门连接符合VDI/VDE 3845 (NAMUR)标准

- 定位器和位置传感器的连接点符合VDI/VDE 3845 标准 AA 1 尺寸。

- 根据 VDMA 66413 标准,设备类型为安全设备

- 安全功能:安全功能包括将驱动装置切换到预设的安全切换位置。此切换动作是通过向相应的压力腔内施加压缩空气来实现的。产生的扭矩值取决于压力。

- 安全完整性等级 (SIL)低需求模式下最高可达 SIL 2,冗余架构下最高可达 SIL 3,高需求模式下最高可达 SIL 1

- 该产品已通过 ISO 13849 和 IEC 61508 (SIL) 安全功能认证。该产品可用于 SRP/CS 系统,最高安全等级为 SIL 2(低需求);该产品可用于 SRP/CS 系统,最高安全等级为 SIL 1(高需求);在冗余架构中最高安全等级为 SIL 3。

- 爆破压力24 巴

- 工作压力0.2 MPa 至 0.8 MPa

- 工作压力2 巴至 8 巴

- 工作压力29 psi 至 116 psi

- 额定工作压力0.55 MPa

- 额定工作压力5.5 巴

- 额定工作压力79.75 psi

- 海事分类参见证书

- CE 标志(参见符合性声明)符合欧盟防爆指令 (ATEX)

- UKCA 标记(参见符合性声明)符合英国出口管制条例

- 欧盟以外的防爆认证EPL Db (GB) EPL Gb (GB)

- 防爆等级:1区(ATEX)、1区(UKEX)、2区(ATEX)、21区(ATEX)、21区(UKEX)、22区(ATEX)

- 证书颁发机构:DNV TAP00001CE 德国技术监督协会(TÜV)莱茵 968/V 1106.01/2023

- ATEX II类气体2G

- ATEX 防爆类别II 类粉尘 2D

- 气体防爆点火类型Ex h IIC T4 Gb X

- 防爆点火类型:防爆型(适用于粉尘)Ex h IIIC T105°C Db X

- 爆炸环境温度-20 ℃ <= Ta <= +80 ℃

- 工作介质:压缩空气,符合 ISO 8573-1:2010 [7:4:4] 标准

- 操作和试验介质的注意事项:露点至少比环境温度和介质温度低 10 °C;可进行润滑操作(在这种情况下,始终需要润滑操作)。

- LABS (PWIS) 符合VDMA24364-B1/B2-L

- 储存温度-20 °C 至 60 °C

- 环境温度-20 °C 至 80 °C

- 在额定工作压力和 0° 旋转角度下的扭矩为 20.1 牛米

- 在额定工作压力和 90° 旋转角度下的扭矩为 20.1 牛米

- 关于扭矩的说明:执行器的工作扭矩不得超过 ISO 5211 中列出的最大允许扭矩,该扭矩应参照安装法兰和联轴器的尺寸确定。

- 在 0.6 MPa (6 bar, 87 psi) 压力下,每个循环的空气消耗量(0° – 标称旋转角度 – 0°)为 1.8 升

- 产品重量1275 克

- 轴连接T9

- 气动连接G1/8

- 材料说明:符合RoHS标准

- 基材:阳极氧化锻造铝合金

- 材料覆盖层:涂层压铸铝

- 丁腈橡胶(NBR)材料密封件

- 外壳材质:阳极氧化铝

- 活塞材质:压铸铝

- 承载材料POM

- 凸轮材质:高合金不锈钢

- 螺丝材质:高合金不锈钢

- 轴材质:镀镍钢