I. Product Introduction

Water sampling devices are specialized instruments designed to collect representative water samples from various aquatic environments, including natural water bodies (such as rivers, lakes, oceans, groundwater, and wetlands) and artificial systems (like industrial wastewater tanks, drinking water treatment facilities, and laboratory test containers). Their core function is to obtain water samples that accurately reflect the physical, chemical, and biological properties of the target water body, providing reliable raw materials for subsequent analysis such as water quality monitoring, environmental assessment, scientific research, and compliance testing.

With the increasing emphasis on environmental protection, water resource management, and public health safety, water sampling devices have become indispensable tools in fields such as environmental monitoring, hydrological surveys, industrial quality control, and scientific research. They are widely used by environmental protection departments, hydrological bureaus, water treatment plants, research institutions, and industrial enterprises. Depending on the sampling environment and requirements, water sampling devices can be divided into multiple types, such as manual sampling devices (e.g., sampling bottles, dippers) and automatic sampling devices (e.g., fixed automatic samplers, portable automatic samplers), each adapting to different application scenarios.

II. Product Features

1. High Sample Representativeness

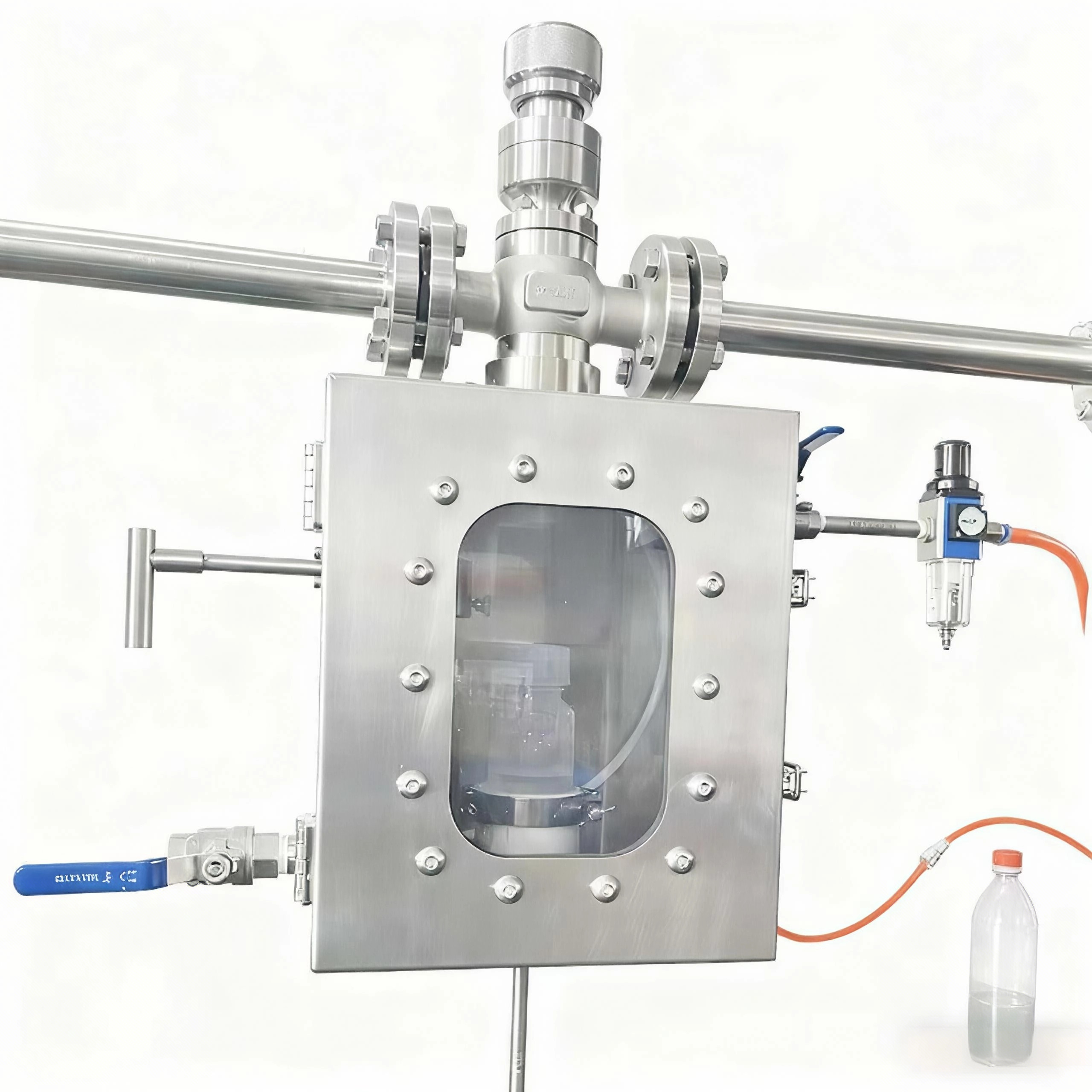

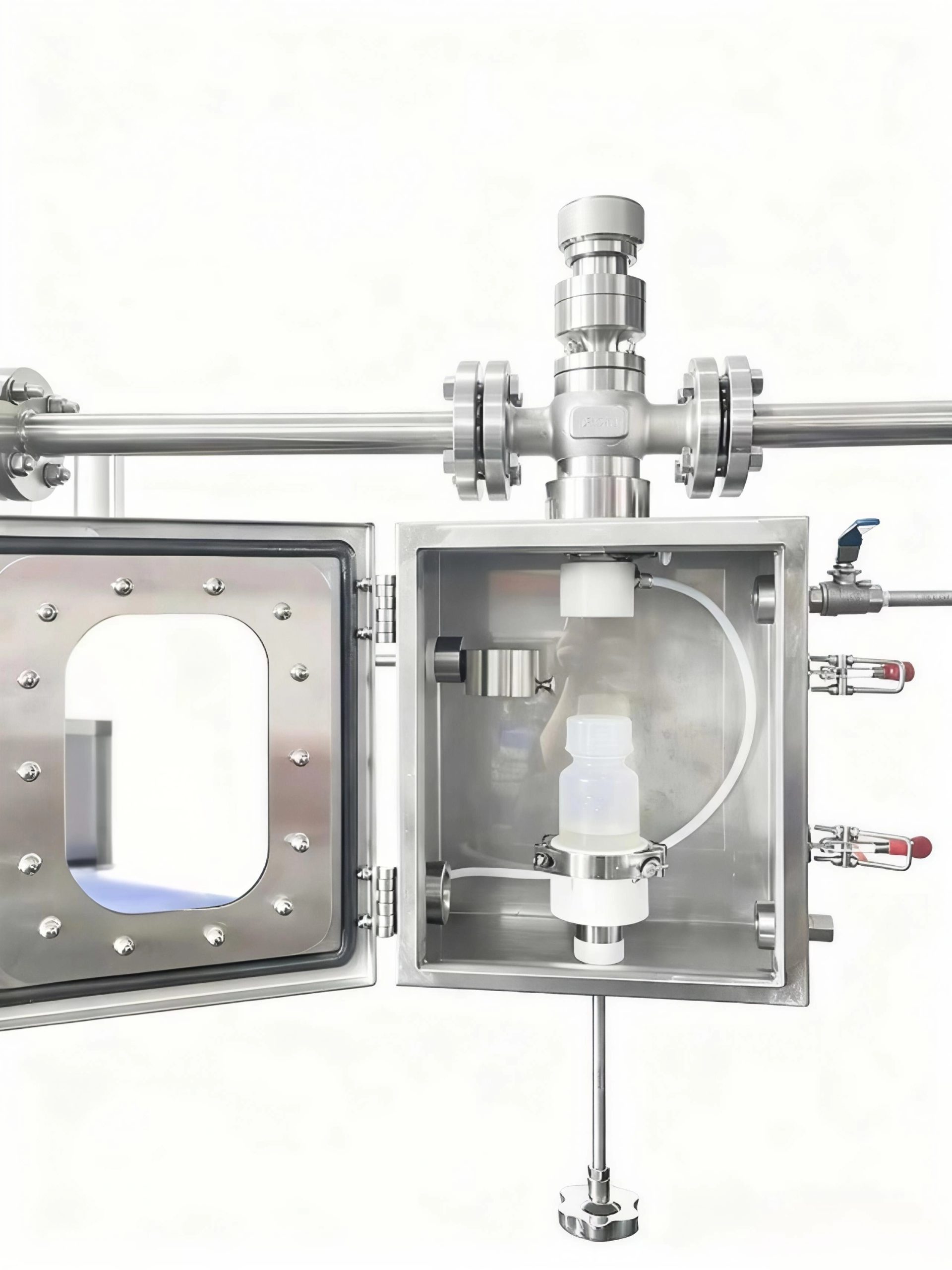

This is the core feature of high-quality water sampling devices. Advanced devices adopt scientific sampling structures, such as isokinetic sampling nozzles and multi-point sampling mechanisms, to avoid sample distortion caused by factors like flow rate deviation and sedimentation during the sampling process. For example, when sampling in rivers with uneven water quality, devices with multi-layer sampling functions can collect samples from different depths simultaneously, ensuring that the combined sample comprehensively reflects the overall water quality of the section. Additionally, the sampling containers and pipelines are made of inert materials (such as PTFE, borosilicate glass) that do not react with water components, preventing contamination or adsorption of target analytes (like heavy metals, organic compounds) and ensuring the authenticity of sample components.

2. Strong Environmental Adaptability

Water sampling devices need to operate in diverse and complex environments, so they are designed with excellent adaptability. For field sampling scenarios, portable devices are lightweight (usually weighing less than 5kg) and equipped with rechargeable lithium batteries, supporting continuous operation for 8-12 hours to meet the needs of long-term outdoor work. They also have waterproof and dustproof functions (reaching IP67 or higher protection level), enabling normal use in rainy days or dusty construction sites. For special environments, there are dedicated devices: deep-sea sampling devices can withstand high pressure of 1000m underwater; high-temperature water sampling devices are suitable for hot springs or industrial high-temperature wastewater; and corrosion-resistant devices for acidic/alkaline wastewater are made of special alloy materials to resist corrosion from strong acids and alkalis.

3. Diverse Sampling Modes

To meet different sampling purposes, water sampling devices support multiple sampling modes. Common modes include instantaneous sampling, which quickly collects a single sample at a specific time point (suitable for emergency monitoring such as sudden water pollution incidents); continuous sampling, which continuously collects samples at a fixed flow rate for a long time (used for tracking water quality changes over time, such as monitoring the discharge of industrial wastewater); and proportional sampling, which collects samples in proportion to the flow rate of the water body (ensuring that the sample volume is proportional to the water flow, suitable for scenarios where the water flow fluctuates greatly, such as river estuaries). Some advanced automatic samplers can also be programmed to set sampling intervals (e.g., sampling once every 15 minutes) and sampling volume (ranging from 10mL to 1000mL per time), realizing fully automated unattended sampling.

4. User-Friendly Operation and Intelligent Management

Modern water sampling devices pay attention to user experience and intelligent control. Portable devices are equipped with a 3.5-5 inch touch screen, with clear operation interfaces and Chinese/English bilingual prompts, allowing operators to complete parameter setting and sampling initiation with simple touches. Automatic devices can be connected to a central control system via wireless networks (4G, WiFi, or LoRa), enabling remote monitoring of sampling status, parameter adjustment, and data transmission. Additionally, most devices have data recording functions, automatically storing sampling time, location (supporting GPS positioning), sampling volume, and environmental temperature, with a storage capacity of up to 10,000 groups of data. The data can be exported to a computer via USB or Bluetooth for easy statistics and analysis, avoiding manual recording errors.

5. High Reliability and Durability

Water sampling devices are required to have stable performance and long service life. The core components (such as sampling pumps, valves, and sensors) are selected from well-known brand products, undergoing strict quality testing to ensure low failure rates. For example, the sampling pump adopts a peristaltic pump or diaphragm pump structure, which has strong suction capacity (suction lift up to 8-10m) and stable flow rate, and is not easy to be blocked by impurities in water. The outer casing of the device is made of high-strength engineering plastics or stainless steel, which is resistant to impact and wear. After strict environmental testing (such as high and low temperature testing, vibration testing), the device can operate stably in harsh conditions such as -20℃ to 60℃. The average trouble-free working time (MTBF) of mainstream products is more than 5000 hours, and the service life can reach 3-5 years under normal maintenance.

III. Technical Data

|

Technical Parameter

|

Portable Manual Sampler

|

Portable Automatic Sampler

|

Fixed Automatic Sampler

|

|---|---|---|---|

|

Sampling Volume Range

|

50mL-2000mL (adjustable manually)

|

10mL-1000mL per time, total volume up to 10L

|

5mL-2000mL per time, total volume up to 50L

|

|

Sampling Depth

|

0-5m (with telescopic sampling rod)

|

0-30m (with stainless steel sampling cable)

|

0-50m (supporting automatic cable winding)

|

|

Sampling Flow Rate

|

Manual control, 50-500mL/min

|

10-300mL/min (adjustable)

|

5-500mL/min (adjustable, stable accuracy ±5%)

|

|

Sampling Modes

|

Instantaneous sampling

|

Instantaneous, continuous, proportional sampling

|

Instantaneous, continuous, proportional, timed sampling

|

|

Material of Sampling System

|

Borosilicate glass, PTFE

|

PTFE, 316L stainless steel

|

PTFE, 316L stainless steel, PVDF (corrosion-resistant model)

|

|

Protection Level

|

IP65

|

IP67

|

IP68 (outdoor waterproof)

|

|

Power Supply

|

No power supply (manual operation)

|

Rechargeable lithium battery (7.4V/5000mAh) + AC 220V

|

AC 220V (supporting DC 12V backup power)

|

|

Working Temperature Range

|

-10℃ to 50℃

|

-20℃ to 60℃

|

-20℃ to 70℃

|

|

Data Storage

|

Manual recording

|

10,000 groups, supporting USB export

|

50,000 groups, supporting wireless data upload

|

|

Dimensions (L×W×H)

|

200×150×100mm

|

350×250×200mm

|

600×400×500mm

|

|

Net Weight

|

1.5kg

|

4.5kg

|

18kg

|