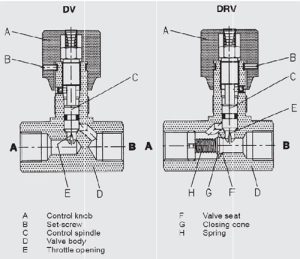

I. Product Introduction

A throttle valve is a critical fluid control component designed to regulate the flow rate, pressure, and direction of gases or liquids in pipeline systems. It achieves precise adjustment by altering the fluid distribution inside the valve, making it widely used in industries such as oil and gas, chemical engineering, water treatment, power generation, and heating, ventilation, and air conditioning (HVAC). Whether in industrial production processes, mechanical equipment operation, or pipeline systems, throttle valves play an irreplaceable role in ensuring system stability, optimizing energy efficiency, and meeting process requirements.

II. Product Features

-

Precise Flow ControlAdopting advanced valve core design and structural sealing, it enables precise flow regulation over a wide range, with low hysteresis and high repeatability.

-

Excellent Durability & VersatilityIt features high resistance to pressure, temperature, corrosion, and wear, making it suitable for various operating conditions and medium types (such as crude oil, natural gas, chemicals, and high-temperature steam).

-

Stable and Reliable OperationThe optimized structural design reduces turbulence and pressure loss, ensuring long-term stable operation, low maintenance costs, and an extended service life.

-

Easy Operation and InstallationIt supports manual, electric, pneumatic, or hydraulic control modes. With a compact structure, it allows for on-site installation, commissioning, and subsequent maintenance with ease.

-

Energy EfficiencyBy precisely controlling flow rate and pressure, it avoids energy waste caused by excessive flow, contributing to the improvement of the overall energy efficiency of the system.

III. Technical Data

| Technical Parameters | Specification Range |

|---|---|

| Nominal Diameter (DN) | DN6 – DN20 (or customized as required) |

| Nominal Pressure (PN) | PN16 – PN400; Class 150 – Class 2500 |

| Operating Temperature | -40℃ – 600℃ (varies by material; high-temperature models can withstand up to 800℃) |

| Flow Coefficient (Cv) | 0.1 – 1500 (depends on nominal diameter and valve structure) |

| Regulation Range | 1:50 – 1:100 (continuously adjustable) |

| Valve Body Material | Carbon steel (WCB), stainless steel (304/316L), alloy steel, Hastelloy, etc. |

| Valve Core Material | Stainless steel, Stellite, ceramics (wear-resistant and corrosion-resistant options available) |

| Sealing Material | PTFE, graphite, metal gaskets (selected according to operating temperature and medium) |

| Control Mode | Manual (handwheel), electric (AC220V/DC24V), pneumatic (0.4-0.6MPa), hydraulic |

| Leakage Class | ANSI Class IV – VI (soft seal up to Class VI; hard seal up to Class V) |

IV. Main Shape and Connection Dimensions

| DN Size | Size Unit (Inch) | Final Connection Standard | Parameter Type | Flow Control Valve | Air Throttle Valve |

|---|---|---|---|---|---|

| DN 6 | 1/8 | BSPP/NPT | Maximum Flow Rate | Up to 20 L/min | Up to 20 L/min |

| DN 8 | 1/4 | BSPP/NPT | Maximum Flow Rate | Up to 50 L/min | Up to 50 L/min |

| DN 10 | 3/8 | BSPP/NPT | Maximum Flow Rate | Up to 60 L/min | Up to 60 L/min |

| DN 12 | 1/2 | BSPP/NPT | Maximum Flow Rate | Up to 90 L/min | Up to 90 L/min |

| DN 16 | 3/4 | BSPP/NPT | Maximum Flow Rate | Up to 180 L/min | Up to 180 L/min |

| DN 20 | 1 | BSPP/NPT | Maximum Flow Rate | Up to 300 L/min | Up to 300 L/min |

| DN 6 – 20 | 1/4” to 1” | BSPP/NPT | Flow Direction | One-way only | Two-way available |

| DN 6 – 20 | 1/4” to 1” | BSPP/NPT | Reason for Flow Direction | Built-in check valve | No internal check valve |

| DN 6 | 1/8 | BSPP/NPT | Working Pressure | 400 bar | 400 bar |

| DN 8 | 1/4 | BSPP/NPT | Working Pressure | 400 bar | 400 bar |

| DN 10 | 3/8 | BSPP/NPT | Working Pressure | 400 bar | 400 bar |

| DN 12 | 1/2 | BSPP/NPT | Working Pressure | 400 bar | 400 bar |

| DN 16 | 3/4 | BSPP/NPT | Working Pressure | 400 bar | 400 bar |

| DN 20 | 1 | BSPP/NPT | Working Pressure | 350 bar | 350 bar |