I. Product Introduction

The Pneumatic Air Soft Seal Butterfly Valve is a high-performance industrial control valve integrated with a pneumatic actuator and a soft-seal butterfly valve core. It is specifically designed for fluid control systems requiring rapid response, reliable sealing, and convenient operation. Relying on compressed air as the power source, the valve drives the butterfly plate to rotate (usually 0-90 degrees of quarter-turn movement) to realize the opening, closing, or throttling regulation of pipelines.

Widely used in water supply and drainage, HVAC (heating, ventilation, and air conditioning), petrochemical, food and beverage, pharmaceutical, textile, and environmental protection industries, this product is suitable for controlling media such as clean water, sewage, air, natural gas, oil, and weak corrosive chemicals. Its core advantage lies in the combination of the pneumatic actuator’s high efficiency and the soft seal’s excellent sealing performance, which not only ensures zero leakage of the medium during shutdown but also meets the requirements of energy saving, environmental protection, and long-term stable operation in industrial production.

Whether in large-scale pipeline networks or precision control systems, the Pneumatic Air Soft Seal Butterfly Valve can adapt to different working conditions through flexible configuration (such as single-acting/bouble-acting actuators, positioners, limit switches, etc.), providing users with safe, efficient, and cost-effective fluid control solutions.

II. Product Features

- Superior Sealing Performance: Adopts high-quality soft seal materials (such as EPDM, NBR, PTFE, etc.) that are resistant to aging, corrosion, and high/low temperatures. The seal ring is closely fitted with the butterfly plate and valve seat, achieving bubble-tight sealing (zero leakage) under normal working conditions, effectively preventing medium loss and environmental pollution.

- Rapid Pneumatic Actuation: Equipped with a high-torque pneumatic actuator (single-acting or double-acting optional). The single-acting type has a spring return function, which can automatically reset to the safe position (open or closed) in case of air supply failure, ensuring system safety; the double-acting type features fast opening and closing speed (generally 3-15 seconds), improving production efficiency and emergency response capabilities.

- Efficient Flow Capacity: The butterfly plate adopts an optimized streamline design with a large flow area and low flow resistance (low CV value loss). It can reduce energy consumption of the pipeline system while ensuring large flow throughput, making it suitable for both on-off control and throttling regulation.

- Durable and Wear-Resistant Structure: The valve body is made of high-quality materials such as cast iron, cast steel, or stainless steel, with high mechanical strength, corrosion resistance, and pressure-bearing capacity. The butterfly plate is treated with precision machining and surface anti-corrosion (such as electroplating, spraying), enhancing wear resistance and extending the service life (average service life of over 10,000 cycles).

- Easy Installation and Maintenance: The valve structure is compact, lightweight, and small in size, which is convenient for on-site installation, disassembly, and transportation. The soft seal ring is designed for quick replacement, and the internal components have good interchangeability, reducing maintenance time and costs.

- Flexible Control Configuration: Supports matching with accessories such as positioners, limit switches, solenoid valves, and air filters. It can realize automatic control, remote monitoring, and signal feedback, seamlessly integrating with PLC, DCS, and other industrial control systems to meet the needs of intelligent production.

- Wide Medium Adaptability: The soft seal material can be customized according to the medium characteristics (such as high temperature resistance, acid and alkali resistance, oil resistance, etc.). It is suitable for various media from ordinary water and air to weak corrosive chemicals, with strong environmental adaptability.

III. Technical Data

| Technical Parameter | Specification |

|---|---|

| Valve Size (DN) | DN40 – DN600 (1.5″ – 24″) |

| Nominal Pressure (PN) | PN1.0 MPa, PN1.6 MPa; ANSI Class 150 |

| Valve Body Material | Cast Iron (HT200), Cast Steel (WCB), Stainless Steel (304/316/316L) |

| Butterfly Plate Material | Carbon Steel, Stainless Steel (304/316/316L), Alloy Steel |

| Soft Seal Material | EPDM (temperature range: -20℃ ~ 120℃), NBR (temperature range: -10℃ ~ 80℃), PTFE (temperature range: -40℃ ~ 180℃) |

| Pneumatic Actuator Type | Double-Acting, Single-Acting (Spring Return) |

| Operating Pressure of Actuator | 0.4 – 0.8 MPa (compressed air) |

| Opening/Closing Time | 3 – 15 seconds (depending on valve size and actuator type) |

| Medium Temperature Range | -40℃ ~ 180℃ (varies with seal material) |

| Medium Compatibility | Clean water, sewage, air, natural gas, gasoline, diesel, weak acid/alkali solutions, food-grade media, etc. |

| Sealing Grade | ANSI/FCI 70-2 Class VI (bubble-tight sealing) |

| Connection Type | Flanged (GB/T 9113, ANSI B16.5, DIN EN 1092), Wafer (GB/T 12224, ANSI B16.22), Lug (optional) |

| Actuator Protection Grade | IP65 (standard), IP67 (optional) |

| Control Signal (with positioner) | 4-20 mA DC (analog signal), ON/OFF signal (digital signal) |

| Accessories (Optional) | Pneumatic positioner, limit switch, solenoid valve, air filter pressure reducer, manual override device |

| Working Environment Temperature | -20℃ ~ 60℃ (outdoor use requires rainproof cover) |

| Vibration Resistance | Meets IEC 60068-2-6 standard |

| Service Life | ≥ 10,000 operating cycles (under normal working conditions) |

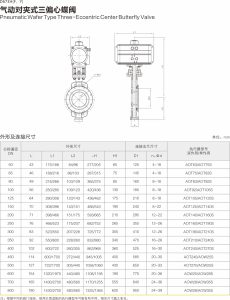

Ⅳ.The main shape and connection size