I. Product Introduction

The Pneumatic Discharge Valve is a specialized automatic control valve designed for material discharge, feeding, and shut-off in bulk material handling systems. It integrates a high-reliability pneumatic actuator with a wear-resistant valve body, mainly used to control the on-off and discharge speed of granular, powdery, or small-particle bulk materials such as cement, coal ash, grain, chemical powder, and mineral powder.

Widely applied in industries including building materials, food processing, chemical engineering, mining, power generation, and grain storage, this valve serves as a key component connecting storage equipment (silos, hoppers) and conveying systems (conveyors, pipelines). Its core advantage lies in realizing rapid, automated material discharge control, effectively avoiding material blockage, leakage, or excessive discharge during the material transfer process. The valve features a robust structure and wear-resistant internal components, ensuring stable operation even in harsh working environments with high dust, frequent switching, and abrasive materials, thus improving the efficiency and safety of bulk material handling systems.

II. Product Features

-

Efficient and Rapid Discharge Control: Equipped with a high-thrust pneumatic actuator, the valve achieves quick opening and closing (response time: 1–5 seconds, depending on valve size), enabling timely control of material discharge start and stop. It supports stepless adjustment of discharge flow when matched with a positioner, adapting to different material conveying speed requirements and avoiding material accumulation or waste caused by unstable discharge.

-

Excellent Sealing and Anti-Leakage Performance: Adopts a double-sealing structure (static seal + dynamic seal) to ensure tight sealing when the valve is closed, effectively preventing air from entering the storage equipment (such as silos) and avoiding material caking or moisture absorption caused by air leakage. The sealing surface is made of wear-resistant and pressure-resistant materials (e.g., PTFE, nitrile rubber, or metal seal), which can resist the abrasion of granular materials and maintain long-term sealing reliability.

-

Wear-Resistant and Corrosion-Resistant Construction: The valve body and internal flow passage components are made of high-strength materials such as carbon steel (WCB) with anti-wear coating, stainless steel (304/316), or wear-resistant alloy steel, which can withstand the scouring and abrasion of hard granular materials. For corrosive materials (e.g., chemical powder), corrosion-resistant materials such as 316L stainless steel or Hastelloy can be selected, extending the valve’s service life in harsh working conditions.

-

Anti-Clogging Design: The internal flow passage adopts a streamlined and large-bore design, minimizing material retention dead angles and effectively preventing material bridging or clogging. The valve plate (or rotor) is designed with a special structure that can scrape off the material attached to the inner wall during operation, ensuring smooth material discharge even for viscous or easy-caking materials.

-

Easy Installation and Maintenance: The valve features a compact and lightweight structure, supporting multiple installation methods such as flange connection and clamp connection, which can be easily installed at the discharge port of silos, hoppers, or conveying pipelines. The split-type design of the actuator and valve body allows for convenient disassembly and maintenance without removing the entire valve from the system, reducing downtime. The pneumatic actuator is equipped with NAMUR standard interfaces, facilitating the connection with solenoid valves, limit switches, and positioners to realize automated control and status monitoring.

-

Strong Environmental Adaptability: It can work stably in harsh environments such as high dust, high temperature, and low temperature, with a working temperature range of -40°C to 250°C. The actuator is equipped with a dust-proof and waterproof shell (protection grade up to IP65), which can effectively resist the erosion of dust and moisture and ensure reliable operation in outdoor or dusty workshops.

III. Technical Data

|

Technical Parameter

|

Specification

|

|---|---|

|

Nominal Diameter (DN)

|

DN50 – DN600 (customizable for special requirements such as large-bore discharge)

|

|

Nominal Pressure (PN)

|

PN0.6 – PN2.5 MPa

|

|

Working Temperature Range

|

-40°C – 250°C (varies by material: ordinary seal: -40°C–150°C; high-temperature seal: -20°C–250°C)

|

|

Applicable Material

|

Granular materials (grain, ore particles), powdery materials (cement, coal ash, chemical powder), small-particle bulk materials, etc.

|

|

Valve Body Material

|

Carbon steel (WCB) with anti-wear coating, Stainless steel (304/316/316L), Wear-resistant alloy steel, Hastelloy (for strong corrosion)

|

|

Valve Plate/Rotor Material

|

Stainless steel (304/316), Wear-resistant alloy steel, Ceramic-coated steel

|

|

Seal Material

|

PTFE, Nitrile rubber (NBR), Fluororubber (FKM), High-temperature resistant silicone rubber, Metal seal (304/316)

|

|

Actuator Type

|

Pneumatic double-acting actuator, Pneumatic single-acting actuator (spring return, providing fail-safe protection)

|

|

Actuator Air Supply Pressure

|

0.4 – 0.8 MPa

|

|

Response Time

|

1 – 5 seconds (varies by valve size and actuator model)

|

|

Leakage Rate

|

Elastomer seal: ≤ 0.1% of nominal flow; Metal seal: ≤ 1% of nominal flow

|

|

Connection Type

|

Flange connection (GB/T, DIN, ANSI, JIS), Clamp connection, Threaded connection (small diameter)

|

|

Control Signal (Optional)

|

4–20 mA DC (with positioner for proportional flow control)

|

|

Protection Grade

|

Actuator: IP54 – IP65; Valve body: IP65 (dust-proof and waterproof)

|

|

Service Life

|

≥ 80,000 cycles (normal working conditions for non-abrasive materials); ≥ 50,000 cycles (abrasive materials)

|

|

Maximum Material Particle Size

|

≤ 50 mm (customizable for larger particles)

|

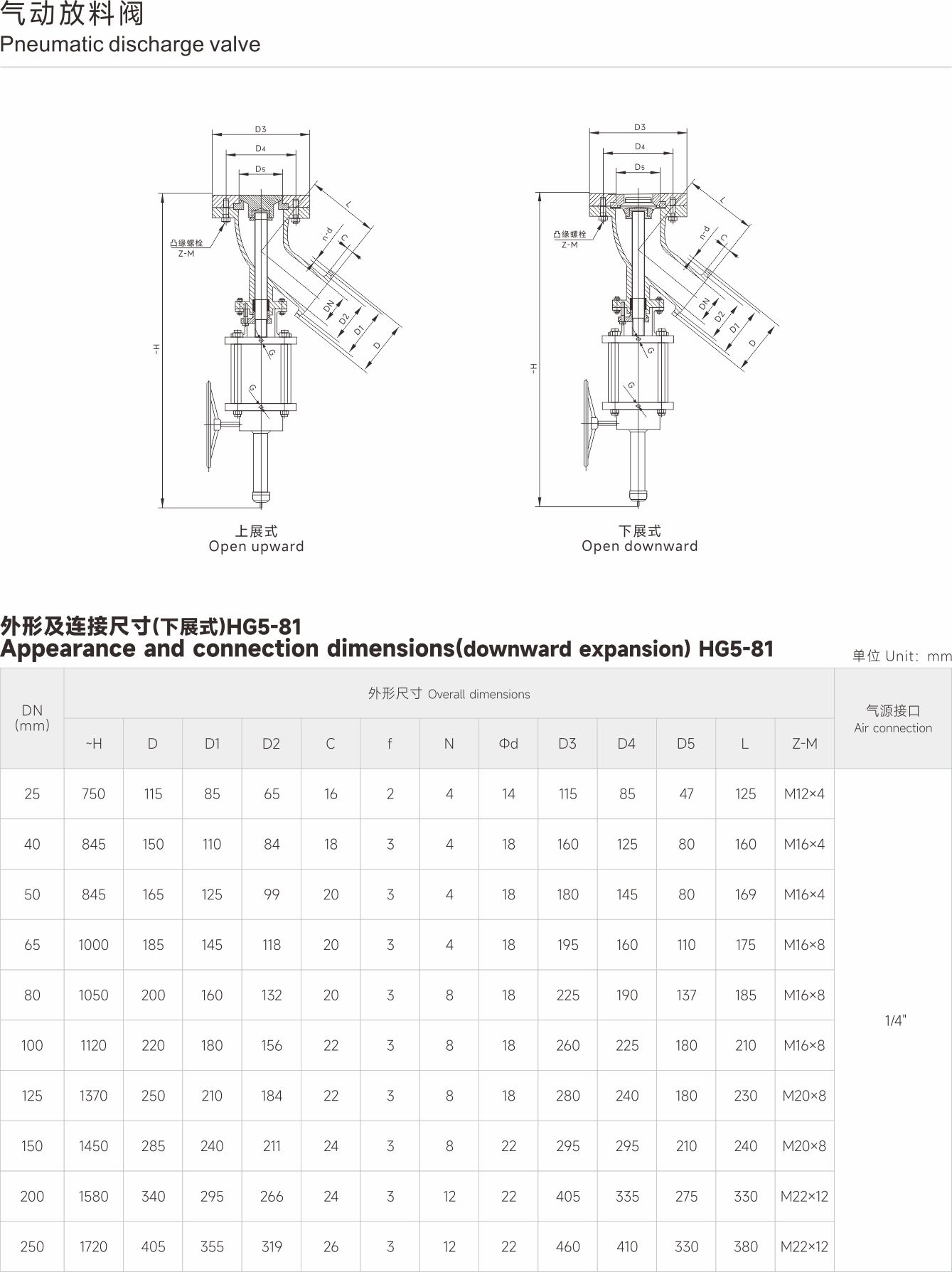

Ⅳ.The main shape and connection size