一.Product Introduction

The electric flange ball valve is an automated flow control device that combines a stainless steel flange ball valve with an electric actuator (the orange component in the figure). It’s widely used in pipelines (e.g., water, oil, gas, chemical media) to remotely or automatically open/close, adjust, and control medium flow. The flange connection ensures tight sealing and easy installation/disassembly, making it suitable for industrial, municipal, and process systems that require efficient, labor-saving flow management.

二.Product Features

- Automated operation: The electric actuator enables remote control (via signals like 4-20mA) or automatic on/off, reducing manual labor and improving control accuracy.

- Reliable sealing: Flange connection + ball valve structure ensures excellent leak-proof performance, even under high pressure/temperature conditions.

- Durable material: Stainless steel valve body resists corrosion, wear, and high temperatures, adapting to various harsh media environments.

- Easy maintenance: Modular design (actuator + valve body) allows quick disassembly for inspection or part replacement, lowering maintenance costs.

- Wide applicability: Compatible with multiple medium types (liquid, gas, low-viscosity fluid) and pipeline pressure grades.

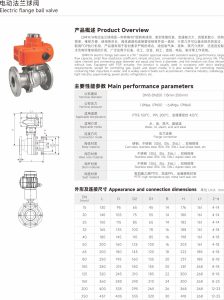

三.Technical data

(Note: Typical specifications; specific parameters vary by model)

- Valve body:

- Material: 304/316 stainless steel

- Connection: Flange (ANSI B16.5, DIN PN16/PN25, GB/T 9113)

- Nominal diameter (DN): DN15 ~ DN200

- Pressure rating: PN16 ~ PN40 (or Class 150 ~ Class 300)

- Temperature range: -20℃ ~ 180℃ (can be extended to -40℃ ~ 300℃ for special materials)

- Electric actuator:

- Power supply: AC220V/380V (or DC24V)

- Control signal: On/off (dry contact) or modulating (4-20mA)

- Protection class: IP65 (dustproof, waterproof)

- Action time: 5 ~ 60s (varies by valve size)

四.The main shape and connection size