一.Product Introduction

The pneumatic gate valve is a pipeline control device driven by a direct stroke pneumatic actuator, mainly used to switch on/off medium flow in pipelines. It is widely applicable to industries such as petroleum, chemical engineering, water treatment, and general fluid systems.

Its core components (body, lashboard, etc.) offer multiple material options (Stainless Steel 304/316, WCB, etc.) to adapt to different working conditions (corrosive/non-corrosive media). The product is designed, manufactured and inspected in accordance with national standards, and supports customized structural length and connecting flange size based on users’ specific requirements.

二.Product Features

- Diverse material adaptation:Core components (body, lashboard, etc.) can be selected from Stainless Steel 304/316 or WCB, matching both corrosive and non-corrosive medium scenarios.

- Strong compliance:Design, structural dimensions, flange connection and inspection all comply with GB series national standards, ensuring product reliability.

- Flexible customization:Structural length and connecting flange size can be designed and manufactured according to users’ actual needs.

- Reliable sealing performance:Adopts PTFE packing to enhance sealing effect and service life.

- High component compatibility:Unified or matched materials of core parts ensure the overall durability and adaptability of the valve.

三.Technical data

1. Design & Manufacturing Standards

| Item | Specification No. |

|---|---|

| Design Basis | GB |

| Design Standard | GB/T 12234 |

| Face to Face Dimension | GB/T 12221 |

| Flange Connecting | GB/T 9113, HG 20592, JB/T 79, GB/T 12224 |

| Test & Inspection | JB/T 9092, GB/T 26480 |

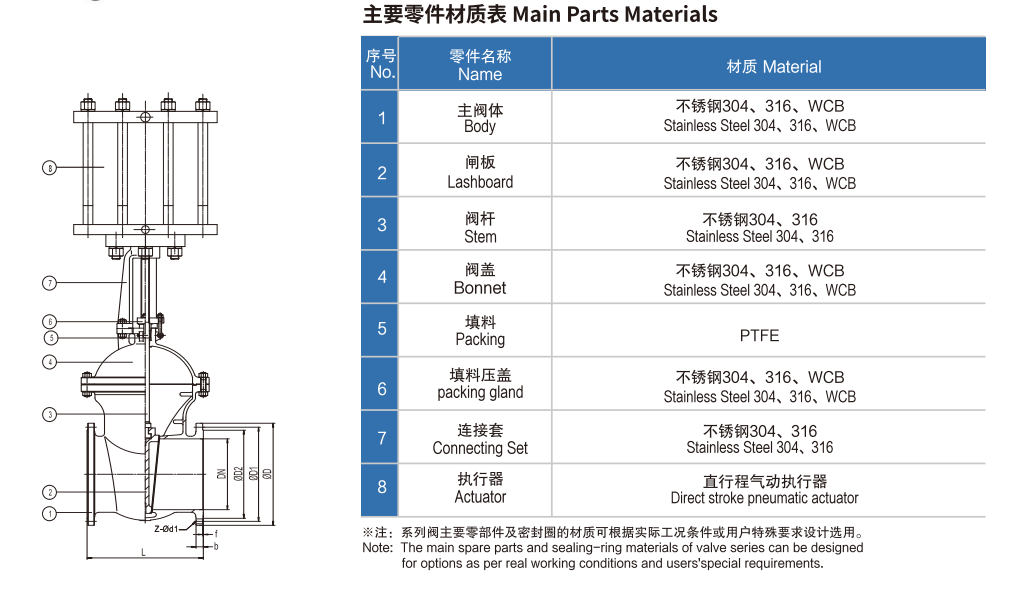

2. Main Parts Materials

| No. | Part Name | Material |

|---|---|---|

| 1 | Body | Stainless Steel 304, 316, WCB |

| 2 | Lashboard | Stainless Steel 304, 316, WCB |

| 3 | Stem | Stainless Steel 304, 316 |

| 4 | Bonnet | Stainless Steel 304, 316, WCB |

| 5 | Packing | PTFE |

| 6 | Packing Gland | Stainless Steel 304, 316, WCB |

| 7 | Connecting Set | Stainless Steel 304, 316 |

| 8 | Actuator | Direct stroke pneumatic actuator |

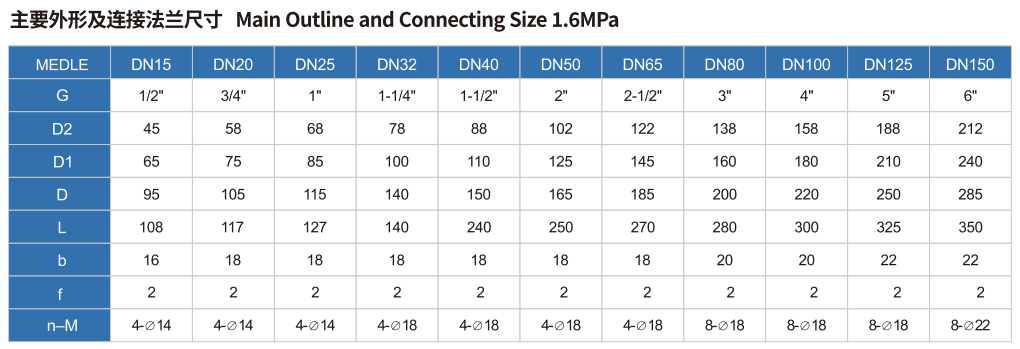

四.The main shape and connection size