I. Product Introduction

II. Product Features

- Full Lining Corrosion Resistance

The valve body, inner cavity, and sealing surface are fully lined with high-quality materials such as FEP, PCTFE, PFA, and PO. This design completely isolates the metal substrate from the medium, providing superior corrosion and chemical resistance, and adapting to various harsh working conditions.

- Swing-open Structure for Reliable Sealing

Adopting a swing-open flap design, the valve realizes automatic opening and closing relying on the pressure difference of the medium. When the medium flows forward, the flap opens smoothly with low flow resistance; when the medium tends to backflow, the flap closes rapidly under the combined action of backflow pressure and its own weight, ensuring tight sealing and effectively preventing backflow.

- Standard Flange Connection

The valve adopts flange connection in accordance with HG/T 20592 standard (or customized according to customer requirements), which is consistent with the installation dimensions of general industrial pipelines. It features simple and quick installation, strong connection stability, and good sealing performance, effectively avoiding pipeline leakage at the connection.

- Diversified Material Configuration

The main components of the valve can be flexibly configured with different materials, including gray cast iron, carbon steel, stainless steel, and ultra-low carbon stainless steel, to adapt to different working pressures, temperatures, and medium characteristics. Customers can choose the most suitable material combination according to actual application scenarios.

- Low Maintenance Cost

The structural design is simple and reasonable, with few wearing parts. The high-quality lining material and precision-machined components ensure the valve’s long service life. In case of failure, only the lining, flap, or sealing parts need to be replaced, without the need for overall valve replacement, greatly reducing the maintenance cost and downtime of the system.

- Compliance with National Standards

The valve is designed, manufactured, and tested in strict accordance with national standards such as GB/T12236, GB/T 12221, and GB/T 13927, ensuring stable product quality, reliable performance, and strong interchangeability, which is convenient for customers to integrate into existing pipeline systems.

III. Technical Data

1. Basic Parameters

| Parameter | Specification |

|---|---|

| Nominal Pressure | PN0.6~1.6 (MPa) |

| Nominal Diameter | DN15~500 (mm) |

2. Implementation Standards

| Standard Category | Standard Number |

|---|---|

| Design and Manufacturing | GB/T12236 |

| Structure Length | GB/T 12221 (long-short series) |

| Flange Size | HG/T 20592 (or as required by the contract) |

| Pressure Test | GB/T 13927 |

| Symbolization | GB/T 12220 |

| Filling | GB/T 12252 |

3. Main Parts and Components Material Table

| Serial Number | Part Name | Gray Cast Iron (Z) | Carbon Steel (C) | Stainless Steels (P) | Stainless Steels (R) | Ultra-low Carbon Stainless Steel (PL) | Ultra-low Carbon Stainless Steel (RL) |

|---|---|---|---|---|---|---|---|

| 1 | Valve body, valve cover | HT250 | WCB | CF8 | CF8M | CF3 | CF3M |

| 2 | Lining/seat | FEP(F46), PCTFE(F3), PFA(Soluble polytetrafluoroethylene), PO(polyolefin) | FEP(F46), PCTFE(F3), PFA(Soluble polytetrafluoroethylene), PO(polyolefin) | FEP(F46), PCTFE(F3), PFA(Soluble polytetrafluoroethylene), PO(polyolefin) | FEP(F46), PCTFE(F3), PFA(Soluble polytetrafluoroethylene), PO(polyolefin) | FEP(F46), PCTFE(F3), PFA(Soluble polytetrafluoroethylene), PO(polyolefin) | FEP(F46), PCTFE(F3), PFA(Soluble polytetrafluoroethylene), PO(polyolefin) |

| 3 | Shaft, Flap (Plate) | 25 | 25 | 1Cr18Ni9/CF8 | 00Cr17Ni14Mo2/CF3M | 1Cr18Ni9/CF8 | 00Cr17Ni14Mo2/CF3M |

| 4 | Bolt (male component of nut and bolt) | 35 | 35 | 0Cr18Ni9 | 0Cr18Ni9 | 0Cr18Ni9 | 0Cr18Ni9 |

| 5 | Nut (female component of nut and bolt) | 45 | 45 | 0Cr18Ni9 | 0Cr18Ni9 | 0Cr18Ni9 | 0Cr18Ni9 |

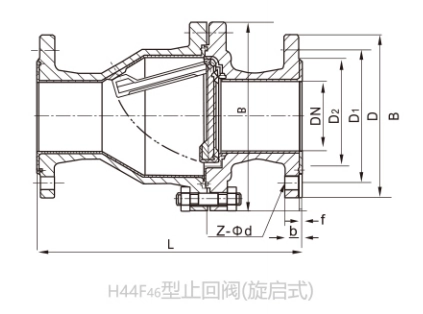

Ⅳ.The main shape and connection size

Main connection dimensions and weight (H44F46)

| Nominal diameter

DN(mm |

Standard value (unit: mm) | reference point | |||||||

| L | D | D1 | D2 | f | b | Z-Φd | H | W(kg) | |

| PN0.6(MPa) | |||||||||

| 15 | 150 | 80 | 55 | 40 | 3 | 12 | 4-Φ11 | 55 | 4 |

| 20 | 150 | 90 | 65 | 50 | 3 | 14 | 4-Φ11 | 58 | 5 |

| 25 | 160 | 100 | 75 | 60 | 3.5 | 14 | 4-Φ11 | 60 | 6 |

| 32 | 180 | 120 | 90 | 70 | 3.5 | 14 | 4-Φ14 | 75 | 7 |

| 40 | 200 | 130 | 100 | 80 | 3.5 | 14 | 4-Φ14 | 82 | 8 |

| 50 | 230 | 140 | 110 | 90 | 4 | 14 | 4-Φ14 | 95 | 10 |

| 65 | 290 | 160 | 130 | 110 | 4 | 14 | 4-Φ14 | 105 | 20 |

| 80 | 310 | 190 | 150 | 128 | 4 | 16 | 4-Φ18 | 120 | 25 |

| 100 | 350 | 210 | 170 | 148 | 4.5 | 16 | 4-Φ18 | 135 | 30 |

| 125 | 400 | 240 | 200 | 178 | 4.5 | 18 | 8-Φ18 | 158 | 50 |

| 150 | 480 | 265 | 225 | 202 | 4.5 | 18 | 8-Φ18 | 180 | 65 |

| 200 | 495 | 320 | 280 | 258 | 5 | 20 | 8-Φ18 | 215 | 137 |

| 250 | 622 | 375 | 335 | 312 | 5 | 22 | 12-Φ18 | 240 | 150 |

| 300 | 698 | 440 | 395 | 365 | 5 | 22 | 12-Φ22 | 265 | 185 |

| 350 | 787 | 490 | 445 | 415 | 5 | 22 | 12-Φ22 | 300 | 215 |

| 400 | 914 | 540 | 495 | 465 | 6 | 22 | 16-Φ22 | 360 | 244 |

| 450 | 978 | 595 | 550 | 520 | 6 | 22 | 16-Φ22 | 385 | 276 |

| 500 | 978 | 645 | 600 | 570 | 6 | 24 | 20-Φ22 | 415 | 315 |

| 600 | 1295 | 755 | 705 | 670 | 6 | 30 | 20-Φ26 | 540 | 410 |

Main connection dimensions and weight (H44F46)

| Nominal diameter

DN(mm) |

Standard value (unit: mm) | reference point | |||||||

| L | D | D1 | D2 | f | b | Z-Φd | H | W(kg) | |

| PN1.0(MPa) | |||||||||

| 15 | 130 | 95 | 65 | 45 | 3 | 16 | 4-Φ14 | 55 | 5 |

| 20 | 150 | 105 | 75 | 58 | 3 | 18 | 4-Φ14 | 58 | 7 |

| 25 | 160 | 115 | 85 | 68 | 3.5 | 18 | 4-Φ14 | 60 | 9 |

| 32 | 180 | 140 | 100 | 78 | 3.5 | 18 | 4-Φ18 | 75 | 11 |

| 40 | 200 | 150 | 110 | 88 | 3.5 | 18 | 4-Φ18 | 82 | 13.5 |

| 50 | 230 | 165 | 125 | 102 | 4 | 18 | 4-Φ18 | 95 | 18 |

| 65 | 290 | 185 | 145 | 122 | 4 | 18 | 8-Φ18 | 105 | 22 |

| 80 | 310 | 200 | 160 | 138 | 4 | 20 | 8-Φ18 | 120 | 28 |

| 100 | 350 | 220 | 180 | 158 | 4.5 | 20 | 8-Φ18 | 135 | 34 |

| 125 | 400 | 250 | 210 | 188 | 4.5 | 22 | 8-Φ18 | 158 | 58 |

| 150 | 480 | 285 | 240 | 212 | 4.5 | 22 | 8-Φ22 | 180 | 72 |

| 200 | 495 | 340 | 295 | 268 | 5 | 24 | 8-Φ22 | 215 | 150 |

| 250 | 622 | 395 | 350 | 320 | 5 | 26 | 12-Φ22 | 240 | 165 |

| 300 | 698 | 445 | 400 | 370 | 5 | 26 | 12-Φ22 | 265 | 190 |

| 350 | 787 | 505 | 460 | 430 | 5 | 26 | 16-Φ22 | 300 | 225 |

| 400 | 914 | 565 | 515 | 482 | 5 | 26 | 16-Φ26 | 360 | 254 |

| 450 | 978 | 615 | 565 | 532 | 6 | 28 | 20-Φ26 | 385 | 285 |

| 500 | 978 | 670 | 620 | 585 | 6 | 28 | 20-Φ26 | 415 | 333 |

| 600 | 1295 | 780 | 725 | 685 | 6 | 34 | 20-Φ30 | 540 | 410 |

Main connection dimensions and weight (H44F46)

| Nominal diameter

DN(mm) |

Standard value (unit: mm) | reference point | |||||||

| L | D | D1 | D2 | f | b | Z-Φd | H | W(kg) | |

| PN1.6(MPa) | |||||||||

| 15 | 130 | 95 | 65 | 45 | 3 | 16 | 4-Φ14 | 55 | 6 |

| 20 | 150 | 105 | 75 | 58 | 3 | 18 | 4-Φ14 | 58 | 7.8 |

| 25 | 160 | 115 | 85 | 68 | 3.5 | 18 | 4-Φ14 | 60 | 10 |

| 32 | 180 | 140 | 100 | 78 | 3.5 | 18 | 4-Φ18 | 75 | 12.5 |

| 40 | 200 | 150 | 110 | 88 | 3.5 | 18 | 4-Φ18 | 82 | 14.5 |

| 50 | 230 | 165 | 125 | 102 | 4 | 18 | 4-Φ18 | 95 | 19.5 |

| 65 | 290 | 185 | 145 | 122 | 4 | 18 | 8-Φ18 | 105 | 25.5 |

| 80 | 310 | 200 | 160 | 138 | 4 | 20 | 8-Φ18 | 120 | 30 |

| 100 | 350 | 220 | 180 | 158 | 4.5 | 20 | 8-Φ18 | 135 | 36 |

| 125 | 400 | 250 | 210 | 188 | 4.5 | 22 | 8-Φ18 | 158 | 62 |

| 150 | 480 | 285 | 240 | 212 | 4.5 | 22 | 8-Φ22 | 180 | 78 |

| 200 | 495 | 340 | 295 | 268 | 5 | 24 | 12-Φ22 | 215 | 156 |

| 250 | 622 | 405 | 355 | 320 | 5 | 26 | 12-Φ26 | 240 | 172 |

| 300 | 698 | 460 | 410 | 378 | 5 | 28 | 12-Φ26 | 265 | 240 |

| 350 | 787 | 520 | 470 | 428 | 5 | 30 | 16-Φ26 | 300 | 208 |

| 400 | 914 | 580 | 525 | 490 | 5 | 32 | 16-Φ30 | 350 | 265 |

| 450 | 978 | 640 | 585 | 550 | 4 | 34 | 20-Φ30 | 385 | 285 |

| 500 | 978 | 715 | 650 | 610 | 4 | 34 | 20-Φ33 | 415 | 333 |

| 600 | 1295 | 840 | 770 | 725 | 6 | 36 | 20-Φ36 | 540 | 410 |