一.Product Introduction

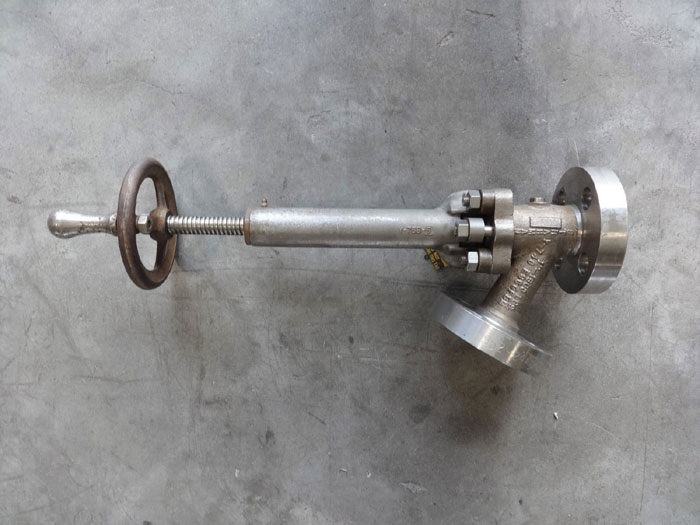

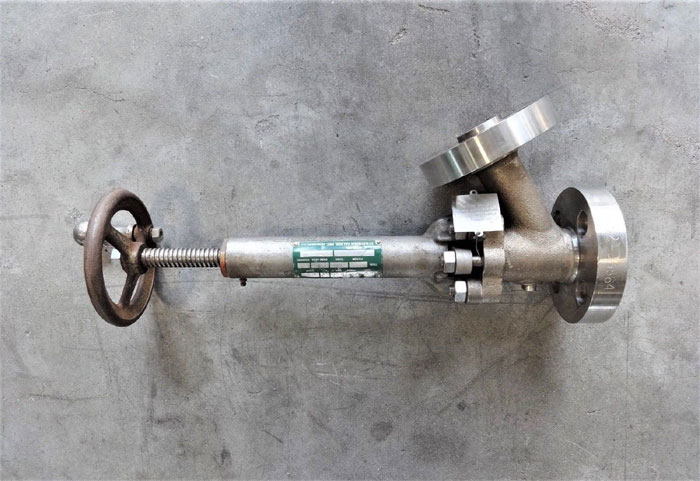

The plunger sampling valve is a V-type plug shut-off valve. Its structure adopts a double-sealing plunger-type sampling form. This plunger sampling valve is produced by some manufacturers referencing foreign samples. It is mainly suitable for sampling, inspection, and sampling of easy-to-crystallize media in chemical plant reactors, and is specially designed for extracting a certain amount of materials in production to check whether they meet the requirements. Some manufacturers use ball valves instead, but the ball valve structure has dead zones and often clogs, which is very troublesome. The stainless steel plunger sampling valve overcomes this shortcoming of the ball valve. Its principle is based on the plunger valve, with a true double-sealing system, combining the structure of the Y-type shut-off valve and the top-mounted discharge valve. There is no dead zone, no residue, and leakage can be avoided.

二.Product Features

- Plunger Structure: Cylindrical cone with a conical tip to prevent process media caking and precipitation at the feed port.

- Discharge & Cleaning: Plunger valve core fully leaves the discharge channel for complete discharge; valve cavity stays clean without affecting process medium flow.

- Custom Design: External plug length can be designed to avoid blockage by high-viscosity materials at the container sampling port.

- Sealing & Temperature: Soft sealing up to 280°C, hard sealing up to 550°C; jacketed insulation shell can be customized.

- Application: Ideal for sampling high-viscosity or easy-crystallization media, with no dead material in pipelines.

三.Technical data

| Item | Specifications |

|---|---|

| Valve Types | Dual-Opening Valve, Flange Clip Valve, Sampling Valve with Insulation Jacket |

| Control Method | Manual (handwheel operation, sequential valve control) |

| Nominal Diameter | DN15~DN200 |

| Maximum Operating Temperature | Up to 200°C |

| Lining Option | Corrosion-resistant lining available (for corrosive media) |

| Sealing Structure | Dual-Opening Valve: Ball valve sealing; Flange Clip Valve: Cone-tapered hole sealing |

| Core Functions | Online sampling (no shutdown required), purge function (residue removal), puncture-type sealed sampling, limit protection (prevents over-operation) |

| Configuration Options | Push-type reset, handwheel switch, handwheel reset |

| Applicable Media | Asphalt, chemical media, petrochemical high-temperature/high-pressure media, pharmaceutical-grade clean media, hazardous chemicals, etc. |

| Design Features | Insulation jacket (for crystalline media), residue-free flow channel, stable structural design |

| Industry Standards | Complies with industrial hydraulic pipeline system application requirements (adaptable to thermal power, chemical, pharmaceutical, food, etc.) |