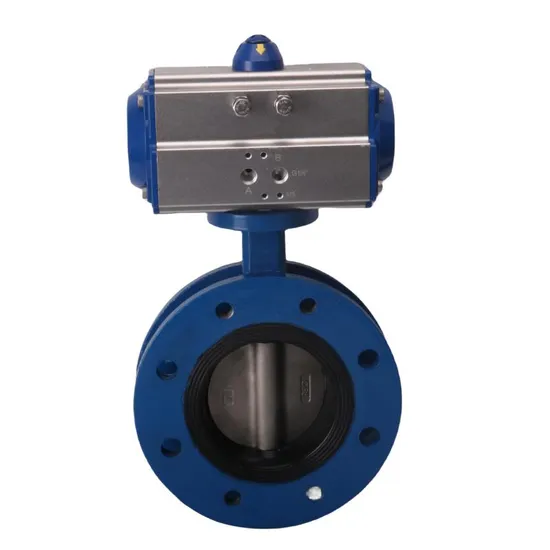

一.Product Introduction

D641W type pneumatic ventilation butterfly valve is made of steel plate welding, which has the characteristics of short structure, light weight and convenient installation. The valve has small driving torque, flexible opening and closing, and convenient operation. The valve body is provided with an oil seal retaining ring, there is no visible gap between the sealing pairs, and the leakage rate is small. The expansion gap between the butterfly plate and the valve body is large, which can effectively prevent the stuck phenomenon caused by thermal expansion and cold contraction

The valve can be equipped with various driving devices, such as manual device, worm gear transmission, pneumatic device, electric device. Ventilation butterfly valves are widely used in metallurgical , petrochemical, electric power, building materials, mining and other industrial pipelines to control or regulate the medium gas.

二.Product Features

1.Simple structure, good interchangeability, and low price.

2.The stem seal is not easily deformed to avoid the normal stem leakage, and the overall support is good, stable and firm.

3.With less seat rubber, there is less potential for expansion and it is easier to control the torque within the proper range.

4.The use of two-piece valve stems with no pin connection, the structure is simple and compact, and maintenance and disassembly are very convenient.

5.The butterfly board has the function of automatic centering, and the butterfly board and valve seat are closely matched.a

6.The phenolic back valve seat has the characteristics of not falling o仔 tensile resistance, leakage prevention

and easy replacement.

7.Surface: Polyester, RAL9006, 100μ

8.Face-to-face: EN558-1

9.Counter flange: DN40-DN300, PN10/16/ANS1150

10.BS10 TABLE D/E JIS 10K 16K

11.DN350 -DN600 PN10 or ANS1150 BS10 TABLE D/E

三.Technical data

| Nominal pressure(MPa) | 0.05MPa | Medium temperature | -30℃~-350℃ |

| Strength test | 0.1MPa | Applicable medium | Cold or hot air, smoke |

| Medium flow rate | 25m/s | Leakage rate | 3% |

| Components | Valve body | Valve plate | Valve shaft |

| Materials | Carbon steel | Carbon steel | Carbon steel, stainless steel |

四.The main shape and connection size

| DN | D | D1 | L | L1 | L2 | n-Фd | b |

| 300 | 405 | 370 | 120 | 716 | 220 | 8-12 | 10 |

| 350 | 455 | 420 | 140 | 786 | 240 | 8-14 | 10 |

| 400 | 505 | 470 | 140 | 924 | 270 | 12-18 | 10 |

| 450 | 570 | 530 | 160 | 999 | 295 | 12-18 | 10 |

| 500 | 620 | 580 | 160 | 1079 | 325 | 12-18 | 10 |

| 600 | 720 | 680 | 180 | 1140 | 380 | 16-18 | 12 |

| 700 | 820 | 780 | 180 | 1240 | 430 | 16-18 | 12 |

| 800 | 920 | 880 | 200 | 1350 | 490 | 16-18 | 12 |

| 900 | 1040 | 990 | 200 | 1450 | 540 | 16-18 | 14 |

| 1000 | 1140 | 1090 | 220 | 1550 | 590 | 20-18 | 14 |

| 1100 | 1240 | 1190 | 220 | 1800 | 640 | 20-18 | 14 |

| 1200 | 1340 | 1290 | 240 | 1900 | 690 | 20-18 | 14 |

| 1300 | 1440 | 1390 | 240 | 2020 | 760 | 20-18 | 16 |

| 1400 | 1540 | 1490 | 260 | 2120 | 810 | 24-18 | 16 |

| 1500 | 1640 | 1590 | 260 | 2220 | 860 | 24-18 | 16 |

| 1600 | 1740 | 1690 | 280 | 2390 | 980 | 24-18 | 16 |

| 1700 | 1840 | 1790 | 280 | 2590 | 1030 | 28-22 | 16 |

| 1800 | 1940 | 1890 | 300 | 2709 | 1096 | 28-22 | 16 |

| 1900 | 2040 | 1990 | 300 | 2826 | 1146 | 32-22 | 16 |

| 2000 | 2150 | 2090 | 320 | 2926 | 1196 | 32-26 | 16 |

| 2200 | 2360 | 2300 | 340 | 3126 | 1296 | 36-26 | 16 |

| 2400 | 2560 | 2500 | 360 | 3326 | 1396 | 36-26 | 18 |

| 2600 | 2760 | 2700 | 380 | 3526 | 1496 | 40-26 | 18 |

| 2800 | 2960 | 2900 | 400 | 3726 | 1596 | 40-26 | 18 |

| 3000 | 3190 | 3110 | 400 | 4098 | 1698 | 44-30 | 18 |

| 3200 | 3390 | 3310 | 440 | 4338 | 1798 | 44-30 | 20 |

| 3400 | 3590 | 3510 | 440 | 4578 | 1898 | 48-30 | 20 |

| 3600 | 3790 | 3710 | 480 | 4780 | 1998 | 48-30 | 20 |

| 3800 | 4000 | 3910 | 480 | 5000 | 2098 | 52-30 | 22 |

| 4000 | 4210 | 4120 | 520 | 5200 | 2210 | 52-30 | 22 |