I. Product Introduction

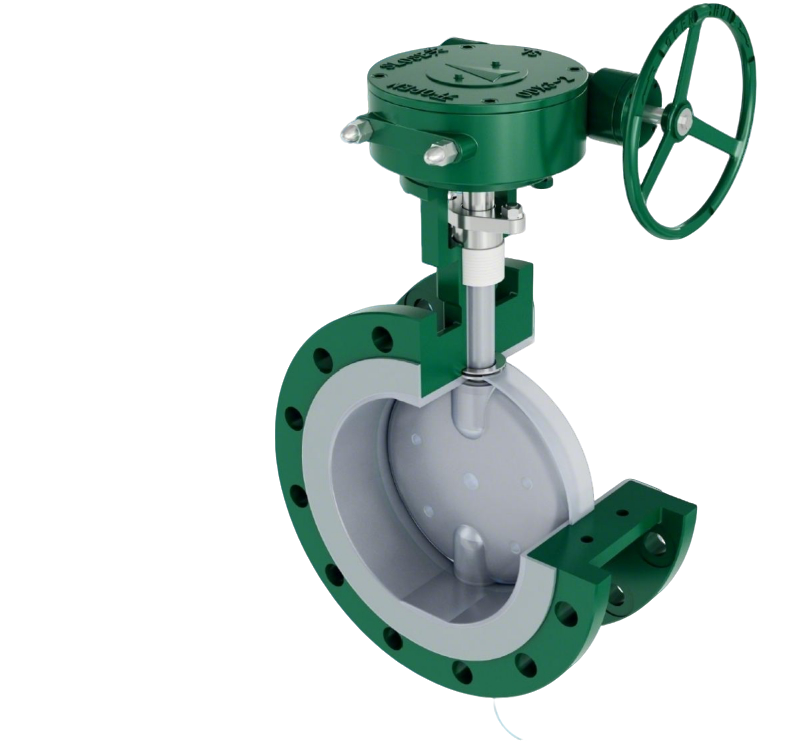

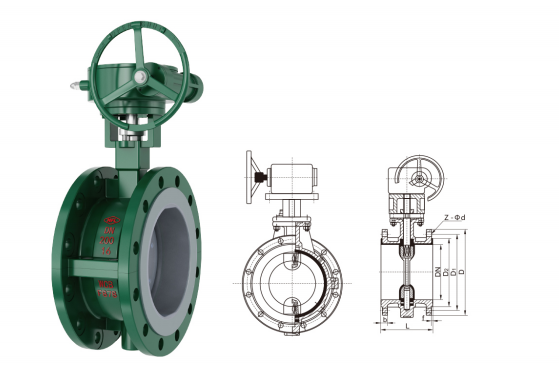

The DA series lined butterfly valve is a high-performance control valve designed for various industrial pipeline systems, mainly used for regulating and cutting off the medium flow. It adopts advanced lining technology and structural design to meet the requirements of different working conditions and medium properties. The series includes two core types: half-lined type (model DA41F4/P) and fully lined type (models DA41F4, DA41F46), which are distinguished by the lining scope of key components.

For the half-lined type (DA41F4/P), the valve body is fully lined, while the butterfly plate and shaft are made of stainless steel without lining, balancing corrosion resistance and structural strength. The fully lined type (DA41F4, DA41F46) features full lining of the valve body, butterfly plate, and butterfly plate shaft; especially, the DA41F46 adopts an integrated structure of the butterfly plate and the shaft, further enhancing the stability and sealing performance of the valve during operation.

The DA series lined butterfly valve supports multiple operation modes, including manual, worm-gear rotation, pneumatic, and electric, to adapt to different automation levels and operation needs of the pipeline system. Its nominal pressure ranges from PN0.6 to 1.6 MPa, and the nominal diameter covers DN40 to 1200 mm, which can be widely applied in chemical, petroleum, pharmaceutical, food, water treatment and other industries, especially suitable for pipelines conveying corrosive media.

II. Product Features

1. Excellent Corrosion Resistance: The core advantage of the DA series lies in its high-quality lining design. The lining/seat of all models adopts corrosion-resistant materials such as F, PFA, and PTFE (packing material is PTFE), which can effectively resist the erosion of various strong corrosive media such as acids, alkalis, and salts. For the fully lined type, the full coverage of the lining ensures that the key flow-passing components are isolated from the medium, maximizing the corrosion resistance and extending the service life of the valve.

2. Diverse Structural Designs for Customized Needs: The series provides half-lined and fully lined options to match different medium corrosion degrees and use scenarios. The half-lined type (DA41F4/P) combines the corrosion resistance of the lined valve body with the high strength of the stainless steel butterfly plate and shaft, suitable for medium-corrosion working conditions; the fully lined type (DA41F4, DA41F46) is designed for strong-corrosion media, and the DA41F46’s integrated butterfly plate and shaft structure avoids potential leakage points caused by assembly, improving sealing reliability.

3. Wide Adaptability of Materials: The main components of the valve can be selected from a variety of materials according to actual needs, including gray iron (HT250), carbon steel (WCB), and stainless steel (CF8, CF8M). This material matching scheme enables the valve to adapt to different pressure levels, temperature ranges, and medium properties, greatly expanding its application scope.

4. Multiple Operation Modes: In addition to the basic manual operation, the series also supports worm-gear rotation, pneumatic, and electric operation modes. The worm-gear rotation mode improves the operation torque and is suitable for large-diameter valves; the pneumatic and electric modes realize automatic control, which can be integrated with the automatic control system of the factory, reducing manual intervention and improving the efficiency and accuracy of pipeline control.

5. Compliance with International Standards: The design, manufacturing, and testing of the valve fully comply with relevant national and international standards (such as GB/T, API, ASME, HG/T), ensuring the consistency of product quality and interchangeability of components. The standardized design also facilitates the maintenance and replacement of the valve in later use.

6. Reasonable Structural Size: The structural length of the valve adopts short-long series design, which is compatible with GB/T 12221 and API 609 standards; the flange size complies with HG/T 20592 and ASME B16.5 standards, ensuring that the valve can be seamlessly connected with various existing pipeline systems, reducing the difficulty of installation and transformation.

III. Technical Data

1. Basic Model Specifications

|

Operation Mode

|

Model

|

Lining Type

|

|---|---|---|

|

Manual

|

D41F/P

|

Half-lined

|

|

DA41F4

|

Fully lined

|

|

|

DA41F46

|

Fully lined

|

|

|

Worm-gear Rotation

|

D341F/P

|

Half-lined

|

|

DA341F4

|

Fully lined

|

|

|

DA341F46

|

Fully lined

|

|

|

Pneumatic

|

D641PFA

|

Half-lined

|

|

DA641F4

|

Fully lined

|

|

|

DA641F46

|

Fully lined

|

|

|

Electric

|

D941PFA

|

Half-lined

|

|

DA941F4

|

Fully lined

|

|

|

DA941F46

|

Fully lined

|

2. Nominal Parameters

-

Nominal Pressure: PN0.6 ~ 1.6 MPa

-

Nominal Diameter: DN40 ~ 1200 mm

3. Main Parts and Components Material

|

Serial Number

|

Part Name

|

Gray Iron

|

Carbon Steel

|

Stainless Steel (Z)

|

Stainless Steel (C)

|

Stainless Steel (P)

|

Stainless Steel (R)

|

|---|---|---|---|---|---|---|---|

|

1

|

Upper and Lower Valve Body

|

HT250

|

WCB

|

CF8

|

CF8

|

CF8

|

CF8M

|

|

2

|

Lining/Seat

|

F, PFA, F

|

F, PFA, F

|

F, PFA, F

|

F, PFA, F

|

F, PFA, F

|

F, PFA, F

|

|

3

|

Butterfly Plate/Stem

|

WCB

|

WCB

|

CF8

|

CF8

|

CF8

|

CF8M

|

|

4

|

Packing Gland

|

WCB

|

WCB

|

CF8

|

CF8

|

CF8

|

CF8M

|

|

5

|

Packing Material

|

PTFE

|

PTFE

|

PTFE

|

PTFE

|

PTFE

|

PTFE

|

4. Implementation Standards

-

Design and Manufacturing: GB/T 12238 (Median Line) / API 609

-

Structure Length: GB/T 12221 (Short-Long Series) / API 609

-

Flange Size: HG/T 20592 / ASME B16.5

-

Pressure Test: GB/T 13927 / API 598

-

Symbolize: GB/T 12220

-

Fill: JB/T 7928

Ⅳ.The main shape and connection size

Main connection dimensions and weight

| Nominal diameter | standard value | reference point | |||||||||

| DN (mm) |

NPS (inch) |

L | D | D1 | D2 | f | b | Z-Φd | Do | H | W(kg) |

| PN0.6(MPa) | |||||||||||

| 40 | 11/2 | 106 | 130 | 100 | 80 | 3 | 14 | 4-Φ14 | 160 | 140 | 10 |

| 50 | 2 | 108 | 140 | 110 | 90 | 3 | 14 | 4-Φ14 | 200 | 160 | 12 |

| 65 | 21/2 | 112 | 160 | 130 | 110 | 3 | 14 | 4-Φ14 | 250 | 160 | 13 |

| 80 | 3 | 114 | 190 | 150 | 128 | 3 | 16 | 4-Φ18 | 250 | 170 | 14 |

| 100 | 4 | 127 | 210 | 170 | 148 | 3 | 16 | 4-Φ18 | 300 | 180 | 16 |

| 125 | 5 | 140 | 240 | 200 | 178 | 3 | 18 | 8-Φ18 | 300 | 275 | 18 |

| 150 | 8 | 140 | 265 | 225 | 202 | 3 | 18 | 8-Φ18 | 200* | 295 | 38 |

| 200 | 10 | 152 | 320 | 280 | 258 | 3 | 20 | 8-Φ18 | 200* | 320 | 74 |

| 250 | 12 | 165/250 | 375 | 335 | 312 | 3 | 22 | 12-Φ18 | 240* | 385 | 105 |

| 300 | 14 | 178/270 | 440 | 395 | 365 | 4 | 22 | 12-Φ22 | 240* | 390 | 142 |

| 350 | 16 | 190/290 | 490 | 445 | 415 | 4 | 22 | 12-Φ22 | 240* | 460 | 179 |

| 400 | 6 | 216/310 | 540 | 495 | 465 | 4 | 22 | 16-Φ22 | 280* | 510 | 220 |

| 450 | 18 | 222/330 | 595 | 550 | 520 | 4 | 22 | 16-Φ22 | 280* | 540 | 268 |

| 500 | 20 | 229/350 | 645 | 600 | 570 | 4 | 24 | 20-Φ22 | 320* | 570 | 378 |

| 600 | 24 | 267/390 | 755 | 705 | 670 | 6 | 30 | 20-Φ26 | 320* | 660 | 608 |

| 700 | 28 | 292/430 | 860 | 810 | 775 | 6 | 24 | 24-Φ26 | 360* | 710 | 1050 |

| 800 | 32 | 318/470 | 975 | 920 | 880 | 6 | 24 | 24-Φ30 | 360* | 780 | 1320 |

| 900 | 36 | 330/510 | 1075 | 1020 | 980 | 6 | 26 | 24-Φ30 | 380* | 885 | 1795 |

| 1000 | 40 | 410/550 | 1175 | 1120 | 1080 | 6 | 26 | 28-Φ30 | 400* | 990 | 1900 |

| 1200 | 48 | 470/630 | 1405 | 1340 | 1295 | 6 | 28 | 32-Φ33 | 400* | 1170 | 2110 |

| 1400 | 56 | 390 | 1630 | 1560 | 1510 | 6 | 32 | 36-Φ36 | 450* | 1365 | – |

| 1600 | 64 | 440 | 1830 | 1760 | 1710 | 6 | 34 | 40-Φ36 | 500* | 1475 | – |

| 1800 | 72 | 490 | 2045 | 1970 | 1920 | 6 | 36 | 44-Φ39 | 550* | 1515 | – |

Main connection dimensions and weight

| Nominal diameter | standard value | reference point | |||||||||

| DN (mm) |

NPS (inch) |

L | D | D1 | D2 | f | b | Z-Φd | Do | H | W(kg) |

| PN1.0(MPa) | |||||||||||

| 40 | 11/2 | 106 | 150 | 110 | 88 | 3 | 18 | 4-Φ18 | 160 | 140 | 10 |

| 50 | 2 | 108 | 165 | 125 | 102 | 3 | 18 | 4-Φ18 | 200 | 160 | 12 |

| 65 | 21/2 | 112 | 185 | 145 | 122 | 3 | 18 | 8-Φ18 | 250 | 165 | 13 |

| 80 | 3 | 114 | 200 | 160 | 138 | 3 | 20 | 8-Φ18 | 250 | 170 | 14 |

| 100 | 4 | 127 | 220 | 180 | 158 | 3 | 20 | 8-Φ18 | 300 | 180 | 16 |

| 125 | 5 | 140 | 250 | 210 | 188 | 3 | 22 | 8-Φ18 | 300 | 275 | 18 |

| 150 | 6 | 140 | 285 | 240 | 212 | 3 | 22 | 8-Φ22 | 200* | 295 | 38 |

| 200 | 8 | 152 | 340 | 295 | 268 | 3 | 24 | 8-Φ22 | 200* | 320 | 74 |

| 250 | 10 | 165/250 | 395 | 350 | 320 | 3 | 26 | 12-Φ22 | 240* | 385 | 105 |

| 300 | 12 | 178/270 | 445 | 400 | 370 | 4 | 26 | 12-Φ22 | 240* | 390 | 142 |

| 350 | 14 | 190/290 | 505 | 460 | 430 | 4 | 26 | 16-Φ22 | 240* | 460 | 179 |

| 400 | 16 | 216/310 | 565 | 515 | 482 | 4 | 26 | 16-Φ26 | 280* | 510 | 220 |

| 450 | 18 | 222/330 | 615 | 565 | 532 | 4 | 28 | 20-Φ26 | 280* | 540 | 268 |

| 500 | 20 | 229/350 | 670 | 620 | 585 | 4 | 28 | 20-Φ26 | 320* | 570 | 378 |

| 600 | 24 | 267/390 | 780 | 725 | 685 | 6 | 34 | 20-Φ30 | 320* | 660 | 608 |

| 700 | 28 | 292/430 | 895 | 840 | 800 | 6 | 34 | 24-Φ30 | 360* | 710 | 1050 |

| 800 | 32 | 318/470 | 1015 | 950 | 905 | 6 | 36 | 24-Φ33 | 360* | 780 | 1320 |

| 900 | 36 | 330/510 | 1115 | 1050 | 1005 | 6 | 38 | 28-Φ33 | 380* | 885 | 1795 |

| 1000 | 40 | 410/550 | 1230 | 1160 | 1110 | 6 | 38 | 28-Φ36 | 400* | 990 | 1900 |

| 1200 | 48 | 470/630 | 1455 | 1380 | 1330 | 6 | 44 | 32-Φ39 | 400* | 1200 | 2150 |

| 1400 | 56 | 390 | 1675 | 1590 | 1535 | 6 | 48 | 36-Φ42 | 450* | 1365 | – |

| 1600 | 56 | 440 | 1915 | 1820 | 1760 | 6 | 52 | 40-Φ48 | 500* | 1475 | – |

*Flange size PN1.0MPa, PN1.6MPa, DN65 The number of bolt holes adopts 4 holes, please note if you have other requirements.

Main connection dimensions and weight

| Nominal diameter | standard value | reference point | |||||||||

| DN (mm) |

NPS (inch) |

L | D | D1 | D2 | f | b | Z-Φd | Do | H | W(kg) |

| PN1.6(MPa) | |||||||||||

| 40 | 11/2 | 106 | 150 | 110 | 88 | 3 | 18 | 4-Φ18 | 160 | 140 | 10 |

| 50 | 2 | 108 | 165 | 125 | 102 | 3 | 18 | 4-Φ18 | 200 | 160 | 12 |

| 65 | 21/2 | 112 | 185 | 145 | 122 | 3 | 18 | 8-Φ18 | 250 | 165 | 13 |

| 80 | 3 | 114 | 200 | 160 | 138 | 3 | 20 | 8-Φ18 | 260 | 170 | 14 |

| 100 | 4 | 127 | 220 | 180 | 158 | 3 | 20 | 8-Φ18 | 300 | 180 | 16 |

| 125 | 5 | 140 | 250 | 210 | 188 | 3 | 22 | 8-Φ18 | 300 | 275 | 18 |

| 150 | 6 | 140 | 285 | 240 | 212 | 3 | 22 | 8-Φ22 | 200* | 295 | 42 |

| 200 | 8 | 152 | 340 | 295 | 268 | 3 | 24 | 12-Φ22 | 200* | 320 | 78 |

| 250 | 10 | 165/250 | 405 | 355 | 320 | 3 | 26 | 12-Φ26 | 240* | 385 | 120 |

| 300 | 12 | 178/270 | 460 | 410 | 378 | 4 | 28 | 12-Φ26 | 240* | 390 | 145 |

| 350 | 14 | 190/290 | 520 | 470 | 428 | 4 | 30 | 16-Φ26 | 240* | 460 | 202 |

| 400 | 16 | 216/310 | 580 | 525 | 490 | 4 | 32 | 16-Φ30 | 280* | 510 | 235 |

| 450 | 18 | 222/330 | 640 | 585 | 550 | 4 | 34* | 20-Φ30 | 280* | 540 | 368 |

| 500 | 20 | 229/350 | 715 | 650 | 610 | 4 | 34* | 20-Φ33 | 320* | 570 | 420 |

| 600 | 24 | 267/390 | 840 | 770 | 725 | 6 | 36* | 20-Φ36 | 320* | 660 | 750 |

| 700 | 28 | 292/430 | 910 | 840 | 795 | 6 | 42 | 24-Φ36 | 360* | 710 | 1028 |

| 800 | 32 | 318/470 | 1025 | 950 | 900 | 6 | 42 | 24-Φ39 | 380* | 780 | 1690 |

| 900 | 36 | 330/510 | 1125 | 1050 | 1000 | 6 | 44 | 28-Φ39 | 400* | 885 | 1815 |

| 1000 | 40 | 410/550 | 1255 | 1170 | 1115 | 6 | 46 | 28-Φ42 | 500* | 990 | 2050 |

Main connection dimensions and weight

| Nominal diameter | standard value | reference point | |||||||||

| DN (mm) |

NPS (inch) |

L | D | D1 | D₂ | f | b | Z-Φd | Do | H | W(kg) |

| PN2.5(MPa) | |||||||||||

| 40 | 11/2 | 106 | 150 | 110 | 88 | 3 | 18 | 4-Φ18 | 200 | 140 | 11 |

| 50 | 2 | 108 | 165 | 125 | 102 | 3 | 20 | 4-Φ18 | 200 | 160 | 13 |

| 65 | 21/2 | 112 | 185 | 145 | 122 | 3 | 22 | 8-Φ18 | 250 | 165 | 14 |

| 80 | 3 | 114 | 200 | 160 | 138 | 3 | 24 | 8-Φ18 | 250 | 170 | 16 |

| 100 | 4 | 127 | 235 | 190 | 162 | 3 | 24 | 8-Φ22 | 300 | 180 | 18 |

| 125 | 5 | 140 | 270 | 220 | 188 | 3 | 26 | 8-Φ26 | 300 | 275 | 20 |

| 150 | 6 | 140 | 300 | 250 | 218 | 3 | 28 | 8-Φ26 | 240* | 295 | 48 |

| 200 | 8 | 152 | 360 | 310 | 278 | 3 | 30 | 12-Φ26 | 240* | 320 | 88 |

| 250 | 10 | 165/250 | 425 | 370 | 335 | 3 | 32 | 12-Φ30 | 280* | 385 | 145 |

| 300 | 12 | 178/270 | 485 | 430 | 395 | 4 | 34 | 16-Φ30 | 280* | 390 | 157 |

| 350 | 14 | 190/290 | 555 | 490 | 450 | 4 | 38 | 16-Φ33 | 320* | 460 | 222 |

| 400 | 16 | 216/310 | 620 | 550 | 505 | 4 | 40 | 16-Φ36 | 320* | 510 | 353 |

| 450 | 18 | 222/330 | 670 | 600 | 555 | 4 | 46 | 20-Φ36 | 360* | 540 | 405 |

| 500 | 20 | 229/350 | 730 | 660 | 615 | 4 | 48 | 20-Φ36 | 360* | 570 | 448 |

| 600 | 24 | 267/390 | 845 | 770 | 720 | 6 | 48* | 20-Φ39 | 380* | 660 | 795 |

Main connection dimensions and weight

| Nominal diameter | standard value | reference point | |||||||||

| DN (mm) |

NPS (inch) |

L | D | D1 | D₂ | f | b | Z-Φd | Do | H | W(kg) |

| Class 150Lb | |||||||||||

| 80 | 3 | 114 | 190 | 152.5 | 127 | 3.5 | 24.3 | 4-Φ19 | 250 | 170 | 14 |

| 100 | 4 | 127 | 230 | 190.5 | 157.2 | 3.5 | 24.3 | 8-Φ19 | 300 | 180 | 16 |

| 125 | 5 | 140 | 255 | 215.9 | 185.7 | 3.5 | 24.3 | 8-Φ22 | 300 | 275 | 18 |

| 150 | 6 | 140 | 280 | 241.3 | 215.9 | 3.5 | 25.9 | 8-Φ22 | 200* | 295 | 42 |

| 200 | 8 | 152 | 345 | 298.5 | 269.9 | 3.5 | 29 | 8-Φ22 | 200* | 320 | 78 |

| 250 | 10 | 165 | 405 | 362 | 323.8 | 4 | 30.6 | 12-Φ25.4 | 240* | 385 | 120 |

| 300 | 12 | 178 | 485 | 431.8 | 381 | 4 | 32.2 | 12-Φ25.4 | 240* | 390 | 145 |

| 350 | 14 | 190 | 535 | 476.3 | 412.8 | 4 | 35.4 | 12-Φ28.6 | 280* | 460 | 202 |

| 400 | 16 | 216 | 595 | 539.8 | 469.9 | 4 | 37 | 16-Φ28.6 | 280* | 510 | 235 |

| 450 | 18 | 222 | 635 | 577.9 | 533.4 | 4 | 40.1 | 16-Φ31.8 | 320* | 540 | 368 |

| 500 | 20 | 229 | 700 | 635 | 584.2 | 4 | 43.3 | 20-Φ31.8 | 320* | 570 | 420 |

| 600 | 24 | 267 | 815 | 749.3 | 692.2 | 6 | 48.1 | 20-Φ34.9 | 360* | 660 | 750 |

Main connection dimensions and weight

| Nominal diameter | standard value | reference point | |||||||||

| DN (mm) |

NPS (inch) |

L | D | D1 | D₂ | f | b | Z-Φd | Do | H | W(kg) |

| Class 300Lb | |||||||||||

| 80 | 3 | 180 | 210 | 168.3 | 127 | 3.5 | 29 | 8-Φ22.2 | 250 | 170 | 16 |

| 100 | 4 | 190 | 255 | 200 | 157.2 | 3.5 | 32.2 | 8-Φ22.2 | 300 | 180 | 18 |

| 125 | 5 | 200 | 280 | 235 | 185.7 | 3.5 | 35.4 | 8-Φ22.2 | 300 | 275 | 20 |

| 150 | 6 | 210 | 320 | 269.9 | 215.9 | 3.5 | 37 | 12-Φ22.2 | 240* | 295 | 48 |

| 200 | 8 | 230 | 380 | 330.2 | 269.9 | 4 | 41.7 | 12-Φ25.4 | 240* | 320 | 88 |

| 250 | 10 | 250 | 445 | 387.4 | 323.8 | 4 | 48.1 | 16-Φ28.6 | 280* | 385 | 145 |

| 300 | 12 | 270 | 520 | 450.8 | 381 | 4.5 | 51.3 | 16-Φ31.8 | 280* | 390 | 157 |

| 350 | 14 | 290 | 585 | 514.4 | 412.8 | 4.5 | 54.4 | 20-Φ31.8 | 320* | 460 | 222 |

| 400 | 16 | 310 | 650 | 571.5 | 469.9 | 5 | 57.6 | 20-Φ34.9 | 320* | 510 | 353 |

| 450 | 18 | 330 | 710 | 628.6 | 533.4 | 5 | 60.8 | 24-Φ34.9 | 360* | 540 | 405 |

| 500 | 20 | 350 | 775 | 685.8 | 584.2 | 6 | 64 | 24-Φ34.9 | 360* | 570 | 450 |

| 600 | 24 | 390 | 915 | 812.8 | 692.2 | 6 | 70.3 | 24-Φ41.3 | 360* | 660 | 765 |