I. Product Introduction

The GB Piston-lift Type Check Valve is a high-performance industrial check valve designed and manufactured in strict accordance with national standards. It is specifically engineered to prevent reverse flow of media in pipeline systems, ensuring the safety, stability, and efficiency of industrial processes.

This valve adopts a reliable piston-lift structure, where the piston disc moves vertically along the guide sleeve with the change of medium flow velocity and pressure difference. When the medium flows forward, the piston is lifted by the fluid pressure, allowing unobstructed passage; when the medium tends to reverse, the piston is quickly closed by the reverse flow pressure and its own weight, achieving an instant seal and effectively preventing backflow.

The valve features a standard flange connection design, which is consistent with universal industrial pipeline specifications and facilitates quick installation and maintenance. It is widely used in petroleum, chemical, power generation, metallurgy, water supply and drainage, and other industrial fields, suitable for various media such as water, steam, oil, gas, and chemical solutions. With excellent sealing performance, sturdy structure, and stable operation, the GB Piston-lift Type Check Valve provides a reliable solution for pipeline systems with strict requirements on reverse flow prevention.

II. Product Features

- Reliable Reverse Flow Prevention: Adopting a precision piston-lift structure, the valve disc moves vertically along the guide sleeve, ensuring fast and tight closing when the medium flow reverses. It effectively prevents backflow, water hammer, and other pipeline problems, protecting pumps, compressors, and other key equipment in the system.

- Excellent Sealing Performance: The piston disc and valve seat are made of high-quality materials and processed with precision. The hard-sealed or soft-sealed structure ensures a tight fit between the sealing surfaces, achieving zero leakage under rated working conditions. Even in long-term operation, the sealing performance remains stable, avoiding safety hazards and economic losses caused by medium leakage.

- Smooth Flow Channel & Low Pressure Loss: The internal flow channel of the valve is designed with a streamlined structure, and the piston-lift design ensures that the valve disc is fully lifted when the medium flows forward, minimizing flow resistance and pressure loss. It improves the overall efficiency of the pipeline system and reduces energy consumption.

- Sturdy and Durable Structure: The valve body and bonnet are made of high-quality carbon steel, stainless steel, or alloy steel, which have excellent mechanical properties, corrosion resistance, and high-temperature resistance. The overall structure is reasonably designed, with strong pressure-bearing capacity and impact resistance, capable of adapting to harsh industrial working environments. The internal components are wear-resistant and fatigue-resistant, significantly extending the service life of the valve.

- Easy Installation and Maintenance: The valve adopts a standard flange connection mode, which is consistent with JB/T79 standards and can be quickly installed and connected without special tools. The valve has a simple internal structure, and the piston disc and guide sleeve are easy to disassemble and replace, facilitating later inspection and maintenance, reducing maintenance costs and downtime.

- Wide Application Range: It can be applied to various media, including water, steam, oil, gas, and various chemical solutions. It is suitable for a wide range of nominal pressures and temperatures, meeting the needs of different industrial fields such as petroleum refining, chemical engineering, thermal power generation, water supply and drainage, and metallurgy.

- Strict Compliance with National Standards: The valve is designed, manufactured, and tested in strict accordance with relevant national standards, ensuring stable product quality and reliable performance. It can be perfectly matched with other national standard pipeline components, improving the interchangeability and compatibility of the system.

III. Technical Data

3.1 Standards

| Standard Item | Specification |

|---|---|

| Design and Manufacture | GB/T12235 |

| Face to Face Dimensions | GB/T12221 |

| End Flange Dimension | JB/T79 |

| Pressure Test | JB/T9092 |

3.2 Test Pressure (MPa)

| Nominal Pressure PN (MPa) | Shell Test (Water) | Seal Test (Water) | Back Seal Test (Water) | Air Seal Test (Air) |

|---|---|---|---|---|

| 1.6 | 2.4 | 1.8 | 1.8 | 0.5~0.7 |

| 2.5 | 3.8 | 2.8 | 2.8 | 0.5~0.7 |

| 4.0 | 6.0 | 4.4 | 4.4 | 0.5~0.7 |

| 6.4 | 9.6 | 7.0 | 7.0 | 0.5~0.7 |

| 10.0 | 15.0 | 11.0 | 11.0 | 0.5~0.7 |

| 16.0 | 24.0 | 18.0 | 18.0 | 0.5~0.7 |

3.3 Materials for Main Parts

| Name | Material |

|---|---|

| Body/Bonnet | CF8, CF3, CF8M, CF3M, WCB, LCB, WC6, WC9, C5 |

| Wedge | CF8, CF3, CF8M, CF3M, WCB, LCB, WC6, WC9, C5 |

| Gasket | PTFE, Graphite |

| Bolt | Stainless Steel, 35CrMoA |

| Nut | Stainless Steel, 45, 35CrMoA |

3.4 Basic Technical Parameters

| Item | Specification |

|---|---|

| Valve Model | GB Piston-lift Type Check Valve |

| Valve Type | Piston-lift Check Valve |

| Nominal Diameter (DN) | DN15 – DN300 |

| Nominal Pressure (PN) | 1.6 MPa, 2.5 MPa, 4.0 MPa, 6.4 MPa, 10.0 MPa, 16.0 MPa |

| Body Material | CF8, CF3, CF8M, CF3M, WCB, LCB, WC6, WC9, C5 |

| Trim Material (Wedge) | CF8, CF3, CF8M, CF3M, WCB, LCB, WC6, WC9, C5 |

| Gasket Material | PTFE, Graphite |

| Connection Type | Flange (JB/T79 standard) |

| Working Medium | Water, Steam, Oil, Gas, Chemical Solutions, etc. |

| Working Temperature Range | Depends on body material (up to 600℃ for alloy steel materials) |

| Sealing Performance | Leakage-free under rated seal test pressure |

| Test Standard | JB/T9092 |

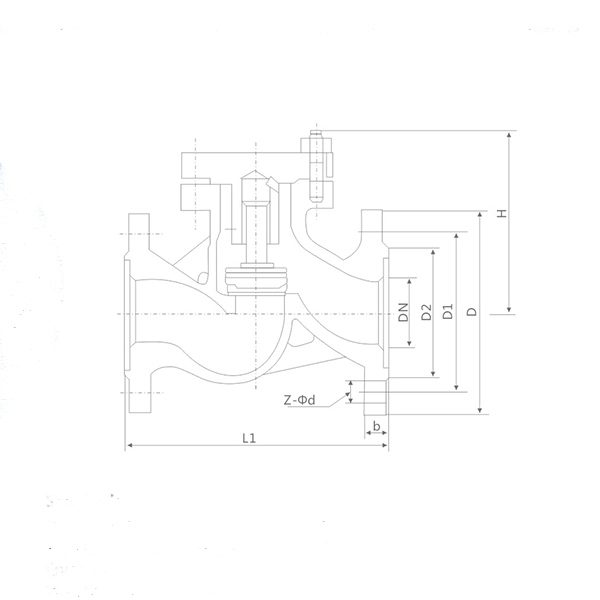

Ⅳ.The main shape and connection size

| Type | DN(mm) | Dimension(mm) | ||||||||

| L | D | D1 | D2 | D6 | b-f | f1 | z- Φd | H | ||

| H

H41W-16 Y |

15 | 130 | 95 | 65 | 45 | 14-2 | 4- Φ14 | 90 | ||

| 20 | 150 | 105 | 75 | 55 | 14-2 | 4-Φ14 | 105 | |||

| 25 | 160 | 115 | 85 | 65 | 14-2 | 4- Φ14 | 115 | |||

| 32 | 180 | 135 | 100 | 78 | 16-2 | 4- Φ18 | 120 | |||

| 40 | 200 | 145 | 110 | 85 | 16-3 | 4- Φ18 | 130 | |||

| 50 | 230 | 160 | 125 | 100 | 16-3 | 4- Φ18 | 140 | |||

| 65 | 290 | 180 | 145 | 120 | 18-3 | 4- Φ18 | 150 | |||

| 80 | 310 | 195 | 160 | 135 | 20-3 | 8- Φ18 | 170 | |||

| 100 | 350 | 215 | 180 | 155 | 20-3 | 8- Φ18 | 185 | |||

| 125 | 400 | 245 | 210 | 185 | 22-3 | 8- Φ18 | 195 | |||

| 150 | 480 | 280 | 240 | 210 | 24-3 | 8- Φ23 | 225 | |||

| 200 | 600 | 335 | 295 | 265 | 26-3 | 12- Φ23 | 250 | |||

| 250 | 650 | 405 | 355 | 320 | 30-3 | 12- Φ25 | 270 | |||

| 300 | 750 | 460 | 410 | 375 | 30-3 | 12- Φ25 | 300 | |||

| H

H41W-25 Y |

15 | 130 | 95 | 65 | 45 | 16-2 | 4-Φ14 | 90 | ||

| 20 | 150 | 105 | 75 | 55 | 16-2 | 4-Φ14 | 105 | |||

| 25 | 160 | 115 | 85 | 65 | 16-2 | 4-Φ14 | 115 | |||

| 32 | 180 | 135 | 100 | 78 | 18-2 | 4- Φ18 | 120 | |||

| 40 | 200 | 145 | 110 | 85 | 18-3 | 4- Φ18 | 130 | |||

| 50 | 230 | 160 | 125 | 100 | 20-3 | 4- Φ18 | 140 | |||

| 65 | 290 | 180 | 145 | 120 | 22-3 | 8- Φ18 | 150 | |||

| 80 | 310 | 195 | 160 | 135 | 22-3 | 8- Φ18 | 170 | |||

| 100 | 350 | 230 | 190 | 160 | 24-3 | 8- Φ23 | 185 | |||

| 125 | 400 | 270 | 220 | 188 | 28-3 | 8- Φ25 | 195 | |||

| 150 | 480 | 300 | 250 | 218 | 30-3 | 8- Φ25 | 225 | |||

| 200 | 600 | 360 | 310 | 278 | 34-3 | 12- Φ25 | 250 | |||

| 250 | 650 | 425 | 370 | 335 | 36-3 | 12- Φ30 | 270 | |||

| 300 | 750 | 485 | 430 | 390 | 40-4 | 16- Φ30 | 300 | |||

| H

H41W-40 Y

|

25 | 160 | 115 | 85 | 65 | 58 | 16-2 | 4 | 4- Φ14 | 115 |

| 32 | 180 | 135 | 100 | 78 | 66 | 18-2 | 4 | 4- Φ18 | 120 | |

| 40 | 200 | 145 | 110 | 85 | 76 | 18-3 | 4 | 4- Φ18 | 130 | |

| 50 | 230 | 160 | 125 | 100 | 88 | 20-3 | 4 | 4- Φ18 | 140 | |

| 65 | 290 | 180 | 145 | 120 | 110 | 22-3 | 4 | 8- Φ18 | 150 | |

| 80 | 310 | 495 | 160 | 135 | 121 | 22-3 | 4 | 8- Φ18 | 170 | |

| 100 | 350 | 230 | 190 | 160 | 150 | 24-3 | 4.5 | 8- Φ23 | 185 | |

| 125 | 400 | 270 | 220 | 188 | 176 | 28-3 | 4.5 | 8- Φ25 | 195 | |

| 150 | 480 | 300 | 250 | 218 | 204 | 30-3 | 4.5 | 8- Φ25 | 225 | |

| 200 | 600 | 375 | 320 | 282 | 260 | 38-3 | 4.5 | 12- Φ30 | 250 | |

| H

H41W-64 Y |

15 | 170 | 105 | 75 | 55 | 40 | 18-2 | 4 | 4- Φ14 | 110 |

| 20 | 190 | 125 | 90 | 68 | 51 | 20-2 | 4 | 4- Φ18 | 125 | |

| 25 | 210 | 135 | 100 | 78 | 58 | 22-2 | 4 | 4- Φ18 | 152 | |

| 32 | 230 | 150 | 110 | 82 | 66 | 24-2 | 4 | 4- Φ23 | 168 | |

| 40 | 260 | 165 | 125 | 95 | 76 | 24-3 | 4 | 4- Φ23 | 170 | |

| 50 | 300 | 175 | 135 | 105 | 88 | 26-3 | 4 | 4- Φ23 | 188 | |

| 65 | 340 | 200 | 160 | 130 | 110 | 28-3 | 4 | 8- Φ23 | 205 | |

| 80 | 380 | 210 | 170 | 140 | 121 | 30-3 | 4 | 8- Φ23 | 230 | |

| 100 | 430 | 250 | 200 | 168 | 150 | 32-3 | 4.5 | 8- Φ25 | 280 | |

| 125 | 500 | 295 | 240 | 202 | 176 | 36-3 | 4.5 | 8- Φ30 | 300 | |

| 150 | 550 | 340 | 280 | 240 | 204 | 38-3 | 4.5 | 8- Φ34 | 350 | |

| 200 | 650 | 405 | 345 | 300 | 260 | 44-3 | 4.5 | 12- Φ34 | 400 | |