I. Product Introduction

The Pipe Flame Arrestor is a critical safety device designed to prevent the propagation of flames from one section of a pipeline to another in systems involving flammable gases, vapors, or liquids. It plays a vital role in protecting industrial equipment, storage tanks, and personnel by interrupting the flame front and dissipating the heat generated during combustion. Widely used in petroleum, chemical, pharmaceutical, food processing, and other industries, this device is engineered to meet strict safety standards and adapt to various harsh working environments. It effectively inhibits deflagration and detonation, ensuring the stable and safe operation of the entire pipeline system.

II. Product Features

-

Excellent Flame Arresting Performance: Adopts high-quality stainless steel fire resistance layer, which can quickly quench the flame and prevent flame propagation, with reliable fire resistance effect.

-

Diversified Material Options: The shell is available in carbon steel and stainless steel, which can be selected according to different working media and environmental requirements to ensure corrosion resistance and service life.

-

Flexible Connection Methods: Supports flange and thread connection modes, which are convenient for installation and disassembly, and can be perfectly matched with various pipeline systems.

-

Wide Pressure Adaptability: The flange pressure ranges from 0.25-4.0MPa to 150-300LB, which can meet the working pressure requirements of different industrial scenarios.

-

Standard Sealing Surface: Equipped with FF, RF, MFM standard flange sealing surfaces, ensuring good sealing performance and avoiding medium leakage.

III. Technical Data

Pipe Flame Arrestor Options Table

|

Technical Parameter

|

Specification

|

|---|---|

|

Nominal Diameter (DN)

|

20-600 (see Parameter Table)

|

|

Shell Material

|

Carbon steel, stainless steel

|

|

Fire Resistance Layer Material

|

Stainless steel

|

|

Connection Mode

|

Flange, thread

|

|

Flange Pressure

|

0.25-4.0MPa、150-300LB

|

|

Flange Sealing Surface

|

FF、RF、MFM

|

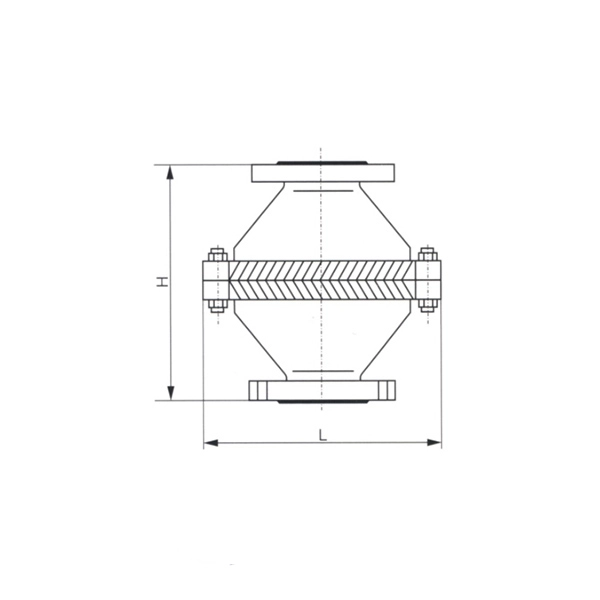

Ⅳ.The main shape and connection size

| DN | L | H |

| 20 | 195 | 200 |

| 25 | 195 | 200 |

| 40 | 245 | 240 |

| 50 | 245 | 240 |

| 80 | 280 | 250 |

| 100 | 335 | 260 |

| 150 | 460 | 360 |

| 200 | 520 | 420 |

| 250 | 580 | 430 |

| 300 | 705 | 450 |

| 600 | 1120 | 580 |