1. Product Introduction

The PN16~PN160 stainless steel globe valve is a manually operated industrial valve featuring flange connection and straight-through structure. It is specifically engineered for precise fluid control in various industrial systems, with nominal pressure ranging from PN16 to PN160. The valve body and seat sealing surface materials are matched in three categories to adapt to different working conditions: 0Cr18Ni9 series stainless steel , 0Cr17Ni12Mo2 series stainless steel , and 1Cr5Mo chrome-molybdenum steel. With its robust construction and material versatility, this globe valve excels in cutting off, throttling and regulating fluid flow, making it widely applicable in petroleum, chemical, power generation, and other industries that demand high reliability and corrosion resistance.

2. Product Features

-

Superior Material Compatibility: The valve body and seat sealing surface adopt matched high-quality materials (0Cr18Ni9, 0Cr17Ni12Mo2, 1Cr5Mo), providing excellent corrosion resistance, high-temperature resistance and mechanical strength to suit diverse mediums and working environments.

-

Reliable Sealing Performance: The precision-machined stainless steel or chrome-molybdenum steel seat sealing surface ensures tight sealing, effectively preventing medium leakage and maintaining stable performance during long-term operation.

-

Broad Pressure Adaptability: Covering a nominal pressure range of PN16 to PN160, the valve can meet the requirements of both low-pressure and high-pressure fluid systems, offering strong versatility in different industrial scenarios.

-

Stable Manual Operation: Equipped with a manual operation mechanism, the valve enables precise adjustment of opening degree with smooth operation. The flange connection design ensures firm installation and easy disassembly for maintenance.

-

Durable Structural Design: The straight-through structure minimizes fluid resistance and reduces erosion on internal components. The high-strength material selection and rigorous manufacturing process extend the valve’s service life even in harsh working conditions.

3. Technical Data

|

Model Series

|

Operation Mode

|

Connection Type

|

Structure Type

|

Nominal Pressure (PN)

|

Valve Body & Seat Sealing Surface Material

|

|---|---|---|---|---|---|

|

J41W-16P~160P

|

Manual

|

Flange

|

Straight-through

|

16~160

|

0Cr18Ni9 Series Stainless Steel

|

|

J41W-16R~160R

|

Manual

|

Flange

|

Straight-through

|

16~160

|

0Cr17Ni12Mo2 Series Stainless Steel

|

|

J41W-16I~160I

|

Manual

|

Flange

|

Straight-through

|

16~160

|

1Cr5Mo Chrome-molybdenum Steel

|

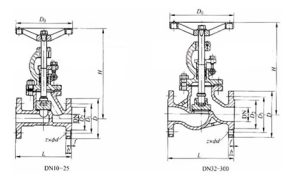

4. The Main Shape and Connection Size

Unit: mm

|

DN

|

L

|

D

|

D1

|

D2

|

b

|

z*Фd

|

H

|

D0

|

Weight (kg)

|

|---|---|---|---|---|---|---|---|---|---|

|

10

|

130

|

90

|

60

|

40

|

14

|

4*Ф14

|

198

|

120

|

5

|

|

15

|

130

|

95

|

65

|

45

|

14

|

4*Ф14

|

200

|

120

|

5.5

|

|

20

|

150

|

105

|

75

|

55

|

14

|

4*Ф14

|

243

|

140

|

7.3

|

|

25

|

160

|

115

|

85

|

65

|

14

|

4*Ф14

|

253

|

160

|

8

|

|

32

|

180

|

135

|

100

|

78

|

15

|

4*Ф18

|

280

|

160

|

12

|

|

40

|

200

|

145

|

110

|

85

|

16

|

4*Ф18

|

312

|

200

|

16

|

|

50

|

230

|

160

|

125

|

100

|

16

|

4*Ф18

|

321

|

200

|

16

|

|

65

|

290

|

180

|

145

|

120

|

18

|

4*Ф18

|

325

|

240

|

22

|

|

80

|

310

|

195

|

160

|

135

|

20

|

4*Ф18

|

355

|

240

|

31

|

|

100

|

350

|

215

|

180

|

155

|

20

|

4*Ф18

|

415

|

280

|

45

|

|

125

|

400

|

245

|

210

|

185

|

22

|

4*Ф18

|

460

|

320

|

80

|

|

150

|

480

|

280

|

240

|

210

|

24

|

8*Ф23

|

510

|

360

|

97

|

|

200

|

600

|

335

|

295

|

265

|

26

|

12*Ф23

|

590

|

360

|

169

|