一.Product Introduction

The Pneumatic fixed ball valve (model: Q647F(N/P/H/Y)) is an automated fluid control device driven by a pneumatic actuator, featuring a fixed ball structure. It covers a wide range of specifications: with a nominal diameter of DN25-600mm and pressure ratings including 1.6-6.4MPa, 150LB-600LB, 10K-20K.

It supports multiple standards (national, American, Japanese) for structural design, and its valve body & internal parts can be made of materials like carbon steel, stainless steel, etc. The sealing components are available in PTFE, PPL, alloy, etc., to adapt to different media and working conditions. Equipped with double-acting/single-acting pneumatic actuators, it can realize on-off control, and can be matched with accessories like limit switches for precise regulation. Its structural length and flange size can also be customized according to user requirements.

二.Product Features

- Fixed ball structure: Ensures stable operation and reliable sealing performance during fluid control.

- Flexible actuator options: Supports double-acting/single-acting pneumatic actuators, adapting to different automatic control needs (e.g., spring return for fail-safe).

- Rich accessory matching: Compatible with limit switches, air source treatment triplets, manual mechanisms, etc., to meet diverse control and operation requirements.

- Diversified material selection: Valve body and internal parts can be tailored (carbon steel, stainless steel, etc.) to adapt to corrosive, high-pressure and other harsh working conditions.

- Standard compliance & customization: Conforms to national standards (GB) for design, testing, etc., and supports customized structural length/flange size to fit specific pipeline systems.

三.Technical data

1. Performance Specifications

| Item | Parameter |

|---|---|

| Model | Q647F(N/P/H/Y) |

| Nominal Diameter | DN25-600mm |

| Pressure Rating | 1.6/2.5/4.0/6.4MPa; 150LB/300LB/600LB; 10K/20K |

| Structure Standard | National, American, Japanese standard |

| Valve Body Material | Carbon steel (WCB), stainless steel (CF8, CF8M, etc.) |

| Sealing Material | PTFE, PPL, alloy (Y), etc. |

| Actuator Type | Double-acting, single-acting (spring return) |

| Control Mode | On-off, adjustment (with matching accessories) |

2. Executive Standards

| Item | GB Standard No. |

|---|---|

| Design Basis | GB/T12237 |

| Structure Length (Flange Connection) | GB/T12221 |

| Connecting Flange Size | GB/T9113, JB/T79 |

| Testing and Inspection | GB/T13927, JB/T7902 |

3. List of Main Parts and Materials

| Serial No. | Part Name | Material (C) | Material (P) | Material (R) |

|---|---|---|---|---|

| 1 | Right Valve Body | WCB | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti |

| 2 | Ball | 35# | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 3 | Spring | 60Si2Mn | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 4 | Valve Seat | 25#Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 5 | Sealing Ring | PTFE/PPL | PPL/alloy | PPL/alloy |

| 6 | O-Ring | Rubber/fluororubber | Rubber/fluororubber | Rubber/fluororubber |

| 7 | Gasket | PTFE/graphite metal | Graphite metal pad | Graphite metal pad |

| 8 | Flange | WCB | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

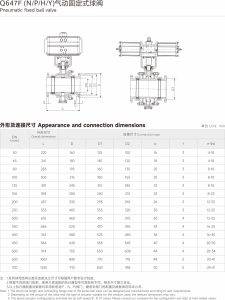

四.The main shape and connection size