I. Product Introduction

The Pneumatic Wafer Type Three-Eccentric Center Butterfly Valve is a high-performance industrial control valve that integrates the advanced three-eccentric structural design, compact wafer connection, and pneumatic actuation system. It uses compressed air as the power source: the pneumatic actuator drives the butterfly plate to rotate 0–90°, thereby achieving precise on-off or throttling control of pipeline fluids.

The “three-eccentric” design (eccentricity of the valve shaft relative to the valve seat center, eccentricity of the butterfly plate cone vertex relative to the valve shaft, and eccentricity of the butterfly plate sealing surface cone) eliminates friction between the butterfly plate and valve seat during opening/closing (a pain point of traditional butterfly valves). Paired with the wafer connection (clamped between pipeline flanges), it balances sealing reliability and space-saving installation, making it ideal for high-pressure, high-temperature, and space-constrained industrial scenarios.

This valve is widely used in petrochemical, thermal power, metallurgy, coal chemical, municipal water treatment, and other industries. It is suitable for controlling media such as steam, superheated steam, high-temperature oil, natural gas, coal gas, and corrosive liquids—especially for pipeline systems requiring high sealing performance, long service life, and automatic control, providing safe, efficient, and stable fluid control solutions.

II. Product Features

- Three-Eccentric Zero-Leakage Sealing: The three-eccentric structure ensures the butterfly plate fully separates from the valve seat during rotation, avoiding sealing pair scratches. With metal hard seals (or metal+PTFE composite seals), it achieves ANSI/FCI 70-2 Class VI zero leakage—maintaining excellent sealing even under high temperature, high pressure, or large pressure differences, preventing medium leakage and environmental pollution.

- Compact Wafer Connection: Clamped between pipeline flanges (complying with GB/T 12224, ANSI B16.22, DIN EN 1092 standards), it saves 30%+ installation space compared to flange valves. No independent flange gaskets are needed (integrated sealing), simplifying assembly and reducing pipeline weight.

- Efficient Pneumatic Actuation: Equipped with high-torque double-acting/single-acting (spring return) actuators:

- Double-acting type: Opens/closes in 3–15 seconds (DN50–DN600), improving system response efficiency.

- Single-acting type: Automatically resets to a safe position (fail-open/fail-close) when air supply is interrupted, ensuring pipeline safety.

- High Temp/Pressure Resistance: Valve body/butterfly plate use carbon steel (WCB), stainless steel (304/316/316L), or alloy steel (WC6/WC9). After precision machining/heat treatment, they withstand medium temperatures up to 450℃ and pressures up to PN6.4 MPa, adapting to harsh working conditions.

- Low Flow Resistance & Energy Saving: The streamlined butterfly plate design has a large flow area and low resistance (high Cv value), reducing pipeline pressure loss and energy consumption—suitable for both on-off control and throttling regulation.

- Long Life & Low Maintenance: Sealing pairs have minimal wear; key components (actuator, valve stem, bearings) use wear/corrosion-resistant materials, achieving ≥100,000 opening/closing cycles. Vulnerable parts are easy to replace, cutting maintenance costs/workload.

- Intelligent Configuration Flexibility: Compatible with optional accessories (pneumatic positioners, limit switches, solenoid valves, air filter regulators), enabling remote control, status monitoring, and signal feedback—seamlessly integrating with PLC/DCS systems for intelligent production.

- Harsh Condition Adaptability: Customizable materials/sealing structures for media (strong corrosion, high viscosity, solid particles) adapt to high-temperature, high-pressure, corrosive, or dusty environments.

III. Technical Data

| Technical Parameter | Specification |

|---|---|

| Valve Type | Pneumatic Wafer Type Three-Eccentric Center Butterfly Valve |

| Nominal Diameter (DN) | DN50 – DN600 (2″ – 24″) |

| Nominal Pressure (PN) | PN1.6, PN2.5, PN4.0, PN6.4 MPa; ANSI Class 150, 300, 600 |

| Valve Body Material | Carbon Steel (WCB), Stainless Steel (304/316/316L), Alloy Steel (WC6/WC9) |

| Butterfly Plate Material | Stainless Steel (304/316/316L), Alloy Steel (1Cr13/2Cr13), Duplex Stainless Steel (2205) |

| Sealing Type & Material | Metal Hard Seal (PTC/Inconel alloy); Metal + PTFE Composite Seal |

| Sealing Grade | ANSI/FCI 70-2 Class VI (Zero Leakage) |

| Medium Temperature Range | -40℃ – 450℃ (varies with material) |

| Medium Compatibility | Steam, superheated steam, high-temperature oil, natural gas, corrosive liquids, etc. |

| Actuator Type | Double-Acting / Single-Acting (Spring Return) |

| Actuator Air Pressure | 0.4 – 0.8 MPa (Compressed Air) |

| Opening/Closing Time | 3 – 15 seconds (DN50 – DN500); 10 – 20 seconds (DN600) |

| Connection Standard | Wafer Type (GB/T 12224, ANSI B16.22, DIN EN 1092) |

| Actuator Protection Grade | IP65 (Standard); IP67 (Optional) |

| Optional Accessories | Pneumatic Positioner (4-20mA), Limit Switch, Solenoid Valve, Manual Override |

| Service Life | ≥ 100,000 Opening-Closing Cycles |

| Working Env Temperature | -20℃ – 60℃ (Outdoor: Rainproof Cover Required) |

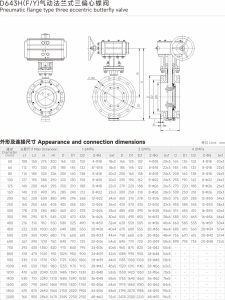

Ⅳ.The main shape and connection size