一.Product Introduction

Q941Y type PN16~PN63 floating hard-sealed electric ball valve: electric drive, flange connection form, floating ball straight-through type, sealing form adopts hard seal, seat sealing surface material is cemented carbide, nominal pressure PN16~PN63, nominal size DN15~DN200, applicable temperature is -28~500℃, valve body material is carbon steel or stainless steel.Due to the use of hard seals (metal seals), this kind of valve is particularly suitable for high-temperature and high-pressure pipelines with granular, solid, slurry and other media.

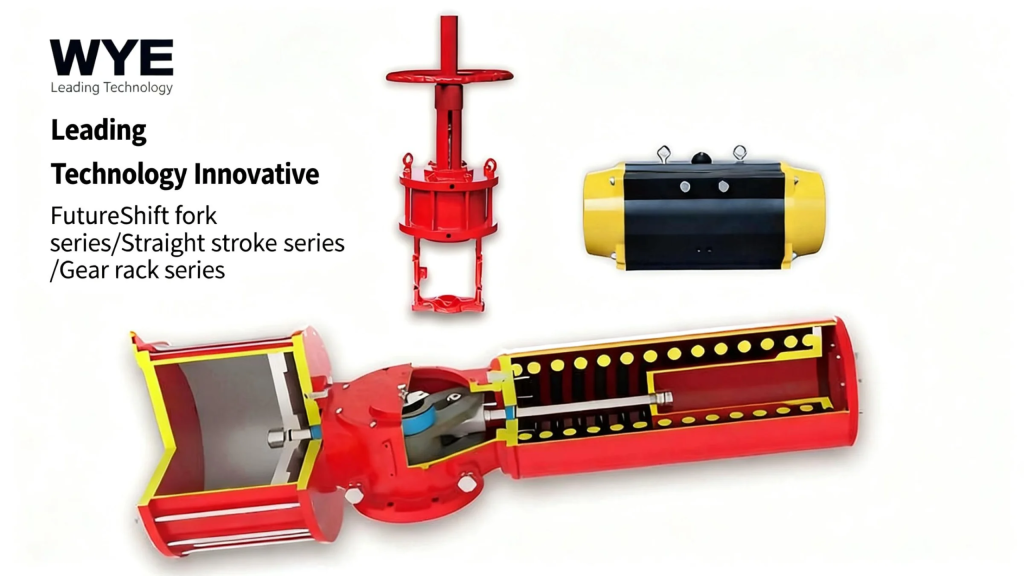

Q941Y type PN16~PN63 floating hard seal electric ball valve is suitable for two-position cutting and adjustment occasions.The connection between the valve and the actuator adopts a direct connection method, which consists of DCL series precision small electric actuators (different types of electronic electric actuators or gas piston actuators can also be configured according to user requirements) and ultra-short ball valves.The electric actuator has a built-in servo system, no need to be equipped with a servo amplifier, and the operation can be controlled by entering a 4-20mA signal and a 220V AC power supply.Compared with ordinary electric ball valves, it has the characteristics of compact structure, small size, light weight, close distance between the valve seat and the end flange, less material retention, and superior sealing performance.

二.Product Features

-

- Actuation and Connection: Features electric drive and flange connection for convenient integration into piping systems.

- Structure and Sealing: Adopts a floating ball straight – through structure with hard seal. The seat sealing surface material is cemented carbide, ensuring reliable sealing performance.

- Pressure and Size Range: Has a nominal pressure of PN16 – PN63 and a nominal size of DN15 – DN200, suitable for various pipeline specifications and pressure requirements.

- Temperature Adaptability: Applicable temperature ranges from -28°C to 500°C, making it viable for high – temperature working conditions.

- Material Options: Valve body material can be carbon steel or stainless steel, providing flexibility to meet different corrosion and strength needs.

- Media Compatibility: Especially suitable for high – temperature and high – pressure pipelines with granular, solid, slurry and other media due to the use of hard (metal) seals.

三.Technical data

| Q941Y – 16C | 16 | 1.6 | -28 – 425 | Water, steam, oil, etc. |

| Q941Y – 25 | 25 | 2.5 | -28 – 425 | Water, steam, oil, etc. |

| Q941Y – 40 | 40 | 4.0 | -28 – 425 | Water, steam, oil, etc. |

| Q941Y – 63 | 63 | 6.3 | -28 – 425 | Water, steam, oil, etc. |

| Q941Y – 16P | 16 | 1.6 | -28 – 500 | Corrosive media such as nitric acid |

| Q941Y – 25P | 25 | 2.5 | -28 – 500 | Corrosive media such as nitric acid |

| Q941Y – 40P | 40 | 4.0 | -28 – 500 | Corrosive media such as nitric acid |

| Q941Y – 63P | 63 | 6.3 | -28 – 500 | Corrosive media such as nitric acid |

| Q941Y – 16R | 16 | 1.6 | -28 – 500 | Corrosive media such as nitric acid |

| Q941Y – 25R | 25 | 2.5 | -28 – 500 | Corrosive media such as nitric acid |

| Q941Y – 40R | 40 | 4.0 | -28 – 500 | Corrosive media such as nitric acid |

| Q941Y – 63R | 63 | 6.3 | -28 – 500 | Corrosive media such as nitric acid |

四.The main shape and connection size

Q941Y type (PN16) flange connection floating hard seal electric ball valve shape and structure size (mm)

| DN | L | D | D₁ | D₂ | b | z×∅d |

| 15 | 130 | 95 | 65 | 45 | 14 | 4×∅14 |

| 20 | 140 | 105 | 75 | 55 | 14 | 4×∅14 |

| 25 | 150 | 115 | 85 | 65 | 14 | 4×∅14 |

| 32 | 165 | 135 | 100 | 78 | 16 | 4×∅18 |

| 40 | 180 | 145 | 110 | 85 | 16 | 4×∅18 |

| 50 | 200 | 160 | 125 | 100 | 16 | 4×∅18 |

| 65 | 220 | 180 | 145 | 120 | 18 | 4×∅18 |

| 80 | 250 | 195 | 160 | 135 | 20 | 8×∅18 |

| 100 | 280 | 215 | 180 | 155 | 20 | 8×∅18 |

| 125 | 320 | 245 | 210 | 185 | 22 | 8×∅18 |

| 150 | 360 | 280 | 240 | 210 | 24 | 8×∅23 |

| 200 | 400 | 335 | 295 | 265 | 26 | 12×∅23 |

Q941Y type (PN25) flange connection floating hard seal electric ball valve shape and structure size (mm)

| DN | L | D | D₁ | D₂ | b | z×∅d |

| 15 | 130 | 95 | 65 | 45 | 16 | 4×∅14 |

| 20 | 140 | 105 | 75 | 55 | 16 | 4×∅14 |

| 25 | 150 | 115 | 85 | 65 | 16 | 4×∅14 |

| 32 | 165 | 135 | 100 | 78 | 18 | 4×∅18 |

| 40 | 180 | 145 | 110 | 85 | 18 | 4×∅18 |

| 50 | 200 | 160 | 125 | 100 | 20 | 4×∅18 |

| 65 | 220 | 180 | 145 | 120 | 22 | 8×∅18 |

| 80 | 250 | 195 | 160 | 135 | 22 | 8×∅18 |

| 100 | 280 | 230 | 190 | 160 | 24 | 8×∅23 |

| 125 | 320 | 270 | 220 | 188 | 28 | 8×∅25 |

| 150 | 360 | 300 | 250 | 218 | 30 | 8×∅25 |

| 200 | 400 | 360 | 310 | 278 | 34 | 12×∅25 |

Q941Y type (PN40) flange connection floating hard seal electric ball valve shape and structure size (mm)

| DN | L | D | D₁ | D₂ | b | z×∅d |

| 15 | 130 | 95 | 65 | 45 | 16 | 4×∅14 |

| 20 | 140 | 105 | 75 | 55 | 16 | 4×∅14 |

| 25 | 150 | 115 | 85 | 65 | 16 | 4×∅14 |

| 32 | 180 | 135 | 100 | 78 | 18 | 4×∅18 |

| 40 | 200 | 145 | 110 | 85 | 18 | 4×∅18 |

| 50 | 220 | 160 | 125 | 100 | 20 | 4×∅18 |

| 65 | 250 | 180 | 145 | 120 | 22 | 8×∅18 |

| 80 | 280 | 195 | 160 | 135 | 22 | 8×∅18 |

| 100 | 320 | 230 | 190 | 160 | 24 | 8×∅23 |

| 125 | 400 | 270 | 220 | 188 | 28 | 8×∅25 |

| 150 | 400 | 300 | 250 | 218 | 30 | 8×∅25 |

| 200 | 502 | 375 | 320 | 282 | 38 | 12×∅30 |

Q941Y type (PN63) flange connection floating hard seal electric ball valve shape and structure size (mm)

| DN | L | D | D₁ | D₂ | b | z×∅d |

| 15 | 140 | 105 | 75 | 55 | 18 | 4×∅14 |

| 20 | 152 | 125 | 90 | 68 | 20 | 4×∅18 |

| 25 | 180 | 135 | 100 | 78 | 22 | 4×∅18 |

| 32 | 200 | 150 | 110 | 82 | 24 | 4×∅23 |

| 40 | 220 | 165 | 125 | 95 | 24 | 4×∅23 |

| 50 | 250 | 175 | 135 | 105 | 26 | 4×∅23 |

| 65 | 280 | 200 | 160 | 130 | 28 | 8×∅23 |

| 80 | 320 | 210 | 170 | 140 | 30 | 8×∅23 |

| 100 | 360 | 250 | 200 | 168 | 32 | 8×∅25 |

| 125 | 381 | 295 | 240 | 202 | 36 | 8×∅34 |

| 150 | 403 | 340 | 280 | 240 | 38 | 12×∅34 |