I. Product Introduction

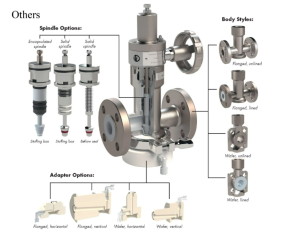

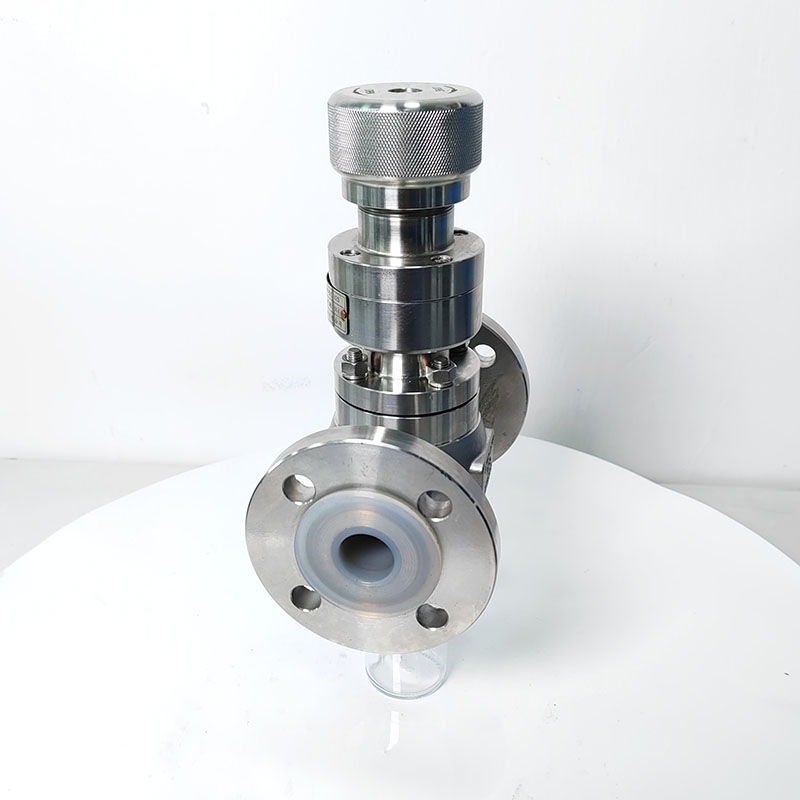

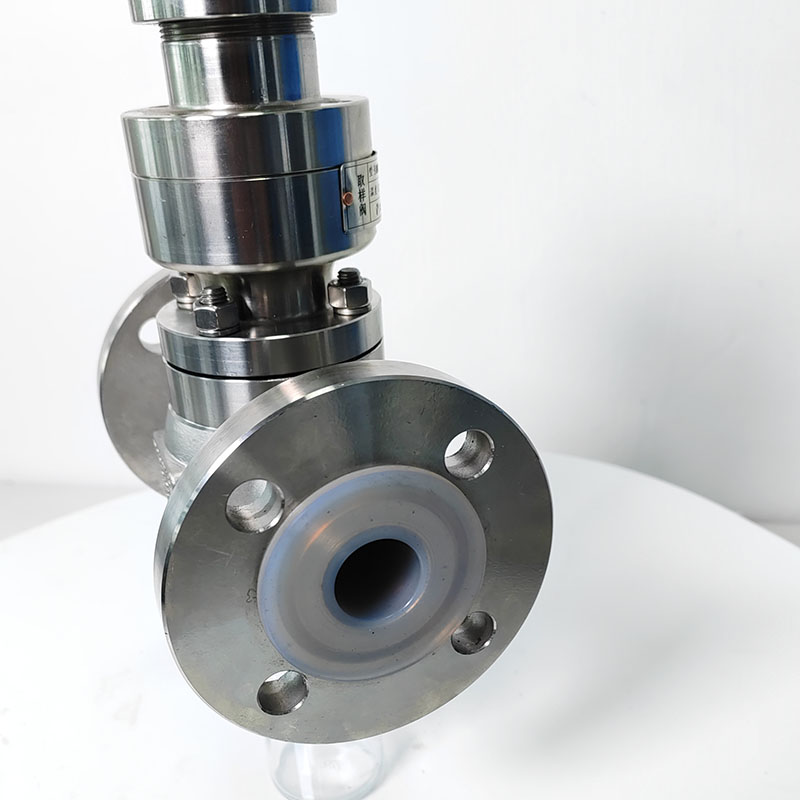

A sampling valve is a specialized valve designed to extract representative samples from pipelines, storage tanks, or other fluid-conveying systems. It enables operators to safely and accurately obtain fluid samples for analysis, thereby ensuring the quality, composition, and compliance of the medium with relevant standards. In industries such as pharmaceuticals, food and beverage, chemical engineering, and petrochemical engineering, sampling valves play a vital role in quality control, process monitoring, and research and development. The sampling valve illustrated in the figure is typically made of high-quality stainless steel, featuring a robust structure that can withstand various operating conditions and media. It is also equipped with components such as flanges for easy integration into existing systems.

II. Product Features

-

Premium Material QualityThese sampling valves are manufactured from high-quality stainless steel, offering excellent corrosion resistance. They are suitable for handling a wide range of corrosive and non-corrosive media, including chemicals, pharmaceuticals, and food-grade liquids.

-

Precise Sampling ControlEquipped with accurate control mechanisms (e.g., handwheels), these valves allow operators to precisely adjust sample flow rates. This ensures that the collected samples are representative and free from contamination or dilution.

-

Hygienic DesignParticularly suitable for pharmaceutical and food industries, these valves comply with stringent hygiene standards. Their smooth surfaces and easy-to-clean structures prevent residue buildup, thus safeguarding the purity of both samples and media.

-

Durable and Robust ConstructionWith a sturdy structure, the valves can withstand high pressure and high temperature commonly encountered in industrial processes. This durability ensures an extended service life and reliable performance.

-

Easy Installation and MaintenanceFeaturing flange connections and a modular design, these sampling valves can be effortlessly installed into existing pipeline systems. Additionally, their simple structure facilitates convenient maintenance and component replacement.

III. Technical Specifications

| Scope | Specifications |

|---|---|

| Material | Stainless steel (e.g., 304, 316, 316L) |

| Connection Type | Flange connection (compliant with relevant industry standards) |

| Nominal Diameter (DN) | Varies by model (e.g., DN10, DN15, DN20, etc.) |

| Pressure Rating | Up to PN16 or higher, suitable for different pressure-bearing requirements |

| Temperature Range | -20℃ to +200℃ (varies by material and model; capable of withstanding low and high temperatures) |

| Sampling Flow Control | Precise manual control via handwheel or other actuators |

| Hygiene Standards | Compliant with FDA, GMP, and other standards for food and pharmaceutical applications |

| Corrosion Resistance | High resistance to acids, alkalis, and other corrosive media |

Ⅳ. Main Shape and Connection Dimensions