1. Product Introduction

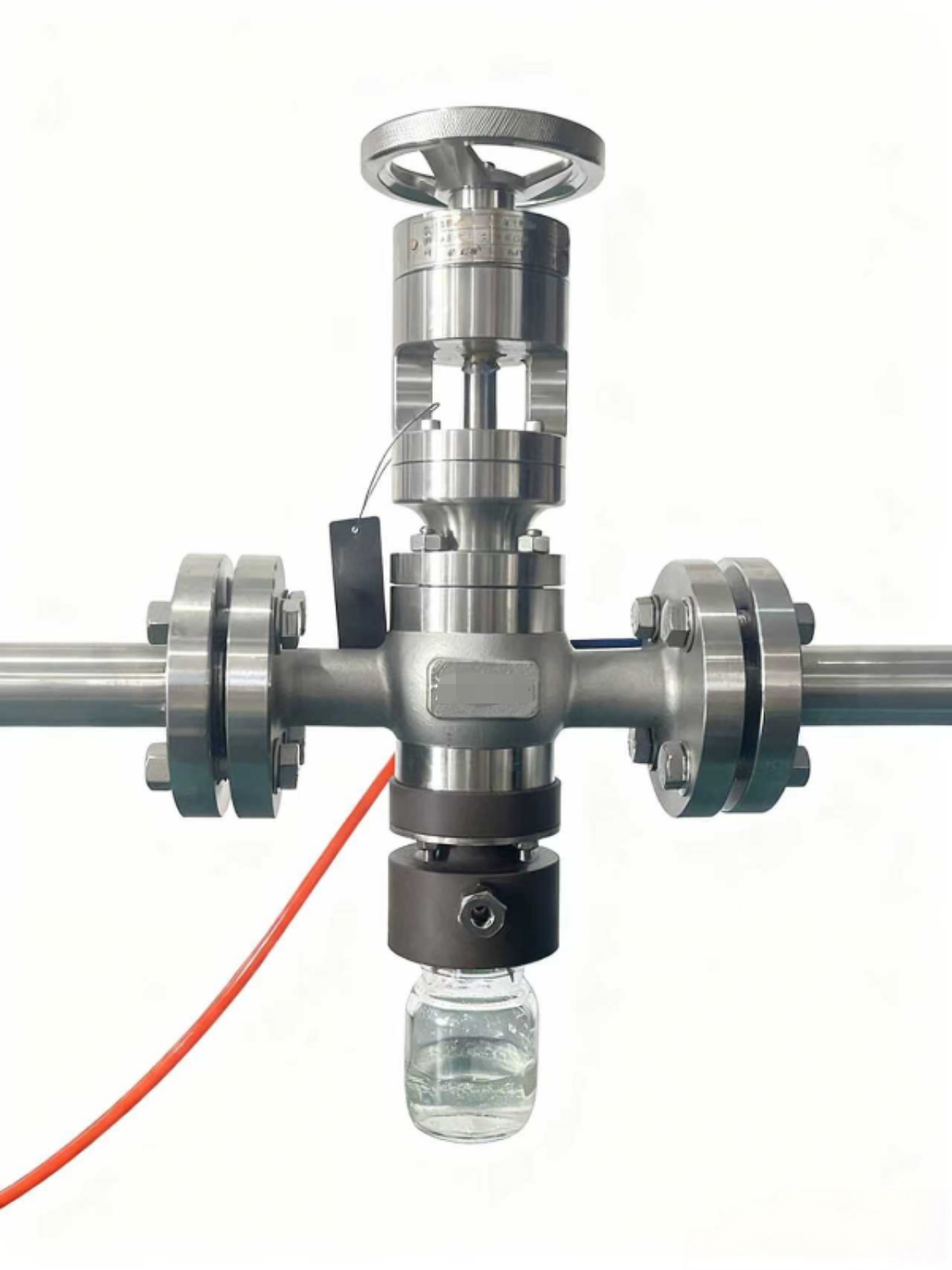

Stainless steel sample valves are specialized fluid control components designed for safe, precise extraction and sampling of media from pipelines, tanks, or industrial systems. Crafted from high-quality stainless steel (e.g., 304, 316L), they excel in resisting corrosion, high/low temperatures, and chemical erosion—making them ideal for industries like petrochemicals, pharmaceuticals, food & beverage, and water treatment. Their core function is to obtain representative media samples without disrupting system operation, ensuring accurate quality testing, compliance monitoring, and process optimization. Unlike ordinary valves, they prioritize sample purity (avoiding cross-contamination) and operational safety (preventing leakage of hazardous media).

2. Product Features

- Superior Corrosion Resistance: Stainless steel material (especially 316L with molybdenum) resists acid, alkali, salt solutions, and organic solvents, adapting to harsh media like crude oil, pharmaceutical intermediates, and food additives.

- High Purity & No Contamination: Smooth internal cavity (polished to Ra ≤ 0.8μm for sanitary scenarios) minimizes media residue; sealed structures (e.g., PTFE, EPDM gaskets) prevent external impurities from mixing into samples, meeting GMP standards for pharmaceuticals/food.

- Stable High/Low Temperature Performance: Withstands temperature ranges typically from -20℃ to 200℃ (customizable to -40℃ to 300℃ for special grades), suitable for both cryogenic liquid sampling and high-temperature steam systems.

- Precise Sampling Control: Equipped with fine-tuning handwheels or lever handles, enabling micro-flow adjustment to obtain representative samples without media waste or system pressure fluctuations.

- Reliable Sealing Performance: Adopts multi-layer sealing structures (e.g., metal-to-metal + soft sealing) to ensure zero leakage, critical for toxic, flammable, or volatile media.

- Durable & Low Maintenance: Stainless steel body resists wear and oxidation; simple structure allows easy disassembly and cleaning, reducing maintenance frequency and costs.

- Versatile Installation: Supports threaded, flanged, or welded connections; available in straight-through, angle, or three-way structures to fit different pipeline layouts and sampling angles.

3. Technical Data

| Item | Specification | Note |

|---|---|---|

| Material | Body: 304/316L stainless steel; Trim: 304/316L; Sealing: PTFE/EPDM/Viton | 316L for stronger corrosion resistance |

| Nominal Diameter (DN) | DN6-DN50 | Common sizes: DN10, DN15, DN20 |

| Nominal Pressure (PN) | PN1.6MPa-PN16MPa | Customizable to PN25MPa for high-pressure systems |

| Temperature Range | -20℃~200℃ (standard); -40℃~300℃ (custom) | Depends on sealing material (e.g., Viton for high temp) |

| Connection Type | Threaded (NPT/G), Flanged (ANSI/JIS/GB), Welded | Sanitary models with clamp connections |

| Flow Coefficient (Cv) | 0.05-1.2 | Varies with DN and valve structure |

| Internal Polishing | Ra ≤ 0.8μm (sanitary); Ra ≤ 1.6μm (industrial) | Sanitary for food/pharmaceutical use |

| Test Standard | Pressure test: GB/T 13927; Leakage test: API 598 | Customizable to international standards |

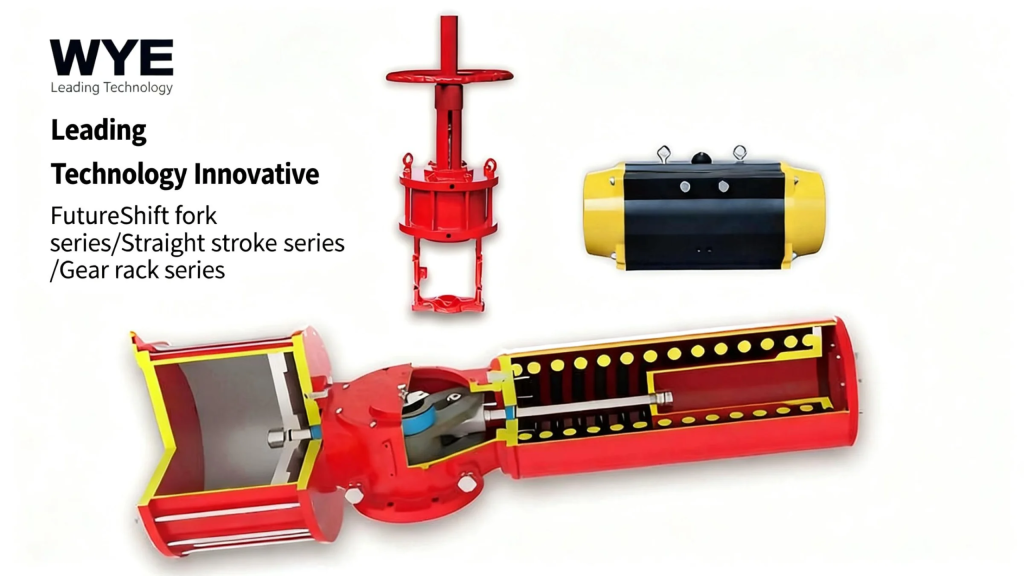

| Operating Mode | Manual (handwheel/lever); Pneumatic/Electric (optional) | Pneumatic for automatic sampling systems |