Although Knife Gate Valves and Gate Valves have similar names, they differ significantly in structure, working principle, and application scenarios. Understanding these differences is crucial for selecting the right valve for specific industrial needs.

Main Differences

Structure and Design

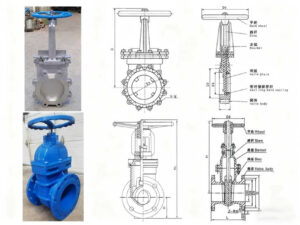

- Knife Gate Valve: The structure is simple and compact, mainly composed of valve body, blade – shaped gate and transmission device, adopting short structure design of wafer type, saving materials and light weight. The bottom of the gate is blade – shaped or V – shaped, which can cut solids or impurities in the medium to prevent blockage.

- Gate Valve: The structure is complex, including multiple parts such as heavy wedge – shaped or parallel double – plate valve plate, valve seat, valve stem, valve body, etc. It is large in size and suitable for conventional piping systems.

Operational Performance

- Knife Gate Valve: Fast opening and closing speed, easy and flexible operation (supports manual, electric, and pneumatic actuation), suitable for scenarios requiring frequent flow regulation.

- Gate Valve: The gate is raised and lowered by the stem, resulting in a longer operation time. It is typically used in low – frequency switching scenarios.

Sealing and Pressure Resistance

- Knife Gate Valve: Using metal or elastic sealing gaskets, providing reliable sealing but with lower pressure resistance (generally suitable for medium and low – pressure systems).

- Gate Valve: Offers superior sealing performance and can withstand high temperatures and pressures (e.g., steam and natural gas pipelines), but the sealing surface is prone to wear from particulate media.

Applicable Media

- Knife Gate Valve: Specializes in handling low – viscosity media such as fiber, pulp, slag, and suspensions (e.g., water, sewage, slurry), with low flow resistance and minimal deposition.

- Gate Valve: Suitable for high – density, high – viscosity, or corrosive media (e.g., oil, chemical fluids), but has poor adaptability to media containing solid particles.

Installation Space

- Knife Gate Valve: Compact structure, suitable for confined spaces.

- Gate Valve: Larger in size, occupies more space.

Application Scenarios

Knife Gate Valve

Suitable for conditions involving media with solid particles or high viscosity, such as:

- Mining and Metallurgy: Slurry, coal slurry transport

- Paper Industry: Pulp, fiber fluids

- Wastewater Treatment: Sludge, sewage, chemical treatment liquids

- Food Industry: Syrup, jam, and other high – viscosity media

Features: Specializes in handling media prone to clogging, effectively cutting through fibers or solid particles.

Gate Valve

Suitable for clean liquids or gases, such as:

- Oil and Gas: Oil, natural gas transportation pipelines

- Water Supply Systems: Potable water, industrial water transport

- Power Industry: Steam, cooling water systems

- Chemical Industry: Acid and alkali liquids

Features: Excellent sealing performance, suitable for applications requiring full opening or closing, but not for flow regulation.

Selection Recommendations

- Preferred selection of knife gate valve: When the working conditions involve large flow, media with suspended solids or fibers, and high requirements for installation space and ease of operation.

- Preferred selection of gate valve: When the system needs to withstand high pressure and temperature (≥10MPa) or has extreme sealing requirements (e.g., flammable or explosive gases).

The above content is a summary from WYVALVE, a gate valve manufacturer. It may be incomplete or contain errors; we appreciate any corrections. For more gate valve guidelines or the latest prices, please feel free to contact us.