一.Product Introduction

The Brass Safety-Type External Threaded Gas Ball Valve is a specialized control component designed for gas transmission systems. Crafted from high-quality brass, it features an external threaded connection structure and integrates safety-oriented designs to ensure reliable on-off control and leak-proof performance during gas conveyance. This valve is widely applied in residential gas pipelines, commercial gas equipment, and small-scale industrial gas systems, serving as a critical safety guarantee for gas supply due to its excellent adaptability to gas media and stable operational performance. It is engineered to meet the strict safety requirements of gas usage scenarios, effectively preventing potential risks such as gas leakage.

二.Product Features

-

Superior Material Performance: Made of high-purity brass, the valve exhibits excellent corrosion resistance, wear resistance, and mechanical strength, which can withstand long-term erosion by gas media and ensure a long service life. The brass material also has good ductility, reducing the risk of cracking due to external impact.

-

Safety-Oriented Design: Adopts multiple safety protection structures (such as enhanced sealing and anti-loosening components) to achieve reliable leak-proof performance, fundamentally avoiding gas leakage accidents. The valve core structure is optimized for sensitive on-off control, enabling quick shut-off in emergency situations to enhance system safety.

-

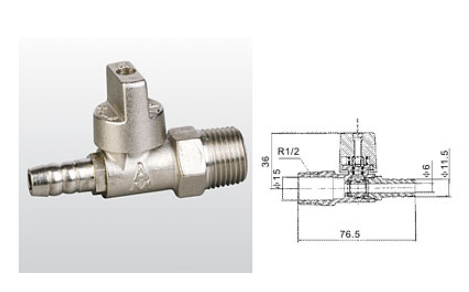

Convenient External Thread Connection: The external threaded connection design allows for quick and firm assembly with gas pipelines, simplifying installation procedures and ensuring tight connection without leakage. It is compatible with standard threaded pipelines, enhancing interchangeability and applicability.

-

Stable Operational Performance: The ball valve core has a smooth flow channel, which minimizes flow resistance during gas transmission and ensures stable gas supply. The operating mechanism is labor-saving and flexible, allowing for easy on-off control with low operating torque.

-

Wide Applicability: Suitable for various common gas media (such as natural gas, liquefied petroleum gas) and applicable to residential, commercial, and small industrial gas pipeline systems, adapting to different usage scenarios.

三.Technical data

|

Item

|

Specifications

|

|---|---|

|

Main Material

|

High-quality brass (HPb59-1 or equivalent)

|

|

Connection Type

|

External thread (complying with GB/T 7307, ANSI B1.20.1, or other relevant standards)

|

|

Nominal Diameter (DN)

|

DN10 – DN50 (customizable according to requirements)

|

|

Working Pressure

|

0.1 – 1.6 Mpa (suitable for medium and low pressure gas systems)

|

|

Operating Temperature

|

-20°C – 80°C (adapts to normal ambient temperature range)

|

|

Applicable Media

|

Natural gas, liquefied petroleum gas (LPG), artificial gas, and other non-corrosive gas media

|

|

Sealing Material

|

Nitrile rubber (NBR), fluororubber (FKM) (optional based on media and temperature)

|

|

Operating Mode

|

Manual (lever or handwheel)

|

|

Safety Certification

|

Complies with relevant gas valve safety standards (e.g., GB 13951, EN 331)

|