一.Product Introduction

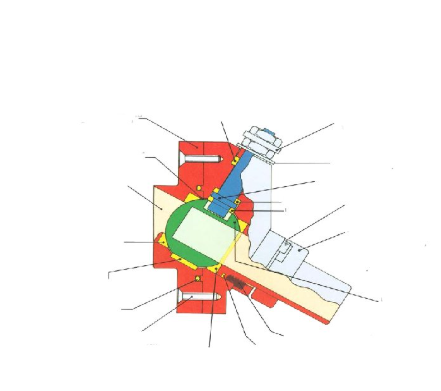

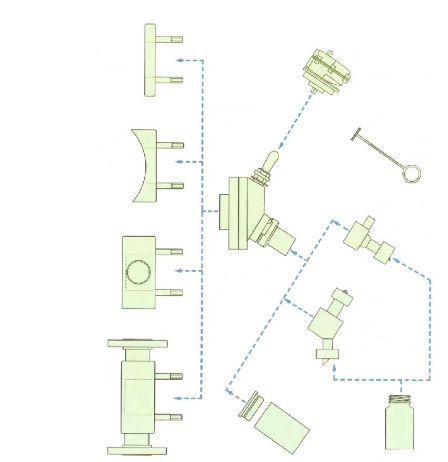

The 1S2A Safety Sampling Valve Series 1 is a precision-engineered safety valve designed for secure and contamination-free sample collection in industrial, pharmaceutical, and chemical applications. Developed to prioritize operator safety and sample integrity, this valve series enables controlled sampling from pipelines, tanks, or process systems while minimizing risks associated with hazardous media or unexpected pressure releases.

Its robust construction and intuitive design make it suitable for critical processes where safety compliance (e.g., GMP, industrial safety standards) and accurate sampling are paramount. Whether in high-pressure environments or applications involving volatile substances, the 1S2A Series 1 delivers reliable performance, ensuring both operational safety and data accuracy.

二.Product Features

- Integrated Safety Mechanism: Equipped with a fail-safe design that prevents accidental media release, protecting operators from exposure to hazardous or pressurized samples.

- Contamination-Free Sampling: Features smooth, crevice-free internal surfaces and sanitary-grade materials (e.g., 316L stainless steel) to eliminate residue buildup and ensure sample representativeness.

- Ergonomic Actuation: The lever-based operation allows for precise control over sample flow, enabling one-handed, intuitive actuation even in demanding working conditions.

- Versatile Installation: Compatible with flange-mounted configurations, adapting to various pipeline sizes and orientations (horizontal/vertical) in process systems.

- High Pressure/Temperature Resistance: Constructed to withstand aggressive process conditions, including elevated pressures and temperatures, without compromising seal integrity or structural stability.

- Regulatory Compliance: Meets industry standards such as GMP, ASME, and FDA requirements, making it suitable for use in highly regulated sectors like pharmaceuticals and food processing.

三.Technical Data

| Parameter | Specification |

|---|---|

| Wetted Material | 316L Stainless Steel |

| Connection Type | Flanged (customizable to industry standards) |

| Nominal Diameter (DN) | DN15, DN20, DN25 (typical sizes) |

| Max Operating Pressure | Up to 25 bar (363 psi) |

| Max Operating Temperature | -20°C to 180°C |

| Seal Material | PTFE, Viton (chemical-resistant, leak-tight) |

| Actuation Type | Manual (Lever-Operated) |

| Compliance | GMP, FDA, ASME BPE |

| Weight | Varies by DN (e.g., ~2–5 kg for DN15–DN25) |