1. Product Introduction

Gases such as oxygen, nitrogen, hydrogen, and argon are frequently used in various industrial and experimental scenarios. These gases are typically stored in specialized high-pressure gas cylinders. During application, the ammonia globe valve (commonly referred to as ammonia valve) is utilized to reduce the gas pressure to the range required for experiments or operations. Subsequently, other control valves perform fine adjustment to deliver the gas into the application system. As a widely used pressure reducing component, the ammonia globe valve plays a crucial role in ensuring the safe and stable supply of gases.

It is important to note that the operating methods and precautions of this ammonia globe valve are generally applicable to similar ammonia valves. However, dedicated ammonia valves are usually not intended for other gases. To prevent misuse, some ammonia valves adopt special connection interfaces with gas cylinders. For instance, hydrogen and propane valves use left-hand threads (also known as reverse threads), which require special attention during installation.

2. Product Features

-

Specialized Structural Design for Ammonia Application: The middle-through flange features a square structure, and the valve stem adopts an intermediate rod connection, ensuring stable structural performance and reliable force transmission during operation.

-

Excellent Sealing Performance: The sealing surface of the valve body is designed with a spherical convex shape, achieving linear fitting sealing with the valve foot. The sealing surface is made of Babbitt alloy, which not only provides superior sealing effectiveness but also extends the service life of the valve significantly.

-

Reliable Connection and Air Tightness: The valve adopts a hemispherical connection method. By tightening the nut, the two hemispherical surfaces fit perfectly, ensuring good air tightness. The smoothness of the hemispherical surfaces is maintained to guarantee sealing performance.

-

Safe and Corrosion-Resistant Material Selection: The valve components are made of materials suitable for ammonia medium, such as cast steel, ductile iron, and malleable iron. The packing is made of PTFE, and gaskets are made of asbestos rubber sheets, all of which contribute to excellent corrosion resistance and adaptability to the working environment.

-

Wide Operating Temperature Range: It can operate stably within the temperature range of -10℃ to 150℃, adapting to various working conditions with different temperature requirements.

3. Technical Data

3.1 Application Specifications

Applicable Medium: Liquid, Gas, Ammonia, Nitrogen, Hydrogen

Applicable Temperature: -10℃ – 150℃

3.2 Test Pressure

|

Nominal Pressure PN (MPa)

|

Shell Strength Test (MPa)

|

Sealing Test (MPa)

|

|---|---|---|

|

1.6

|

2.4

|

1.76

|

|

2.5

|

3.75

|

2.75

|

3.3 Main Component Materials

|

Product Model

|

Valve Body & Bonnet

|

Valve Stem

|

Packing

|

Sealing Surface

|

Gasket

|

Fasteners

|

|---|---|---|---|---|---|---|

|

J41B-16/25C

|

Cast Steel

|

Carbon Steel

|

PTFE (Polytetrafluoroethylene)

|

Babbitt Alloy

|

Asbestos Rubber Sheet

|

High-Quality Carbon Steel

|

|

J41B-16/25Q

|

Ductile Iron

|

Carbon Steel

|

PTFE (Polytetrafluoroethylene)

|

Babbitt Alloy

|

Asbestos Rubber Sheet

|

High-Quality Carbon Steel

|

|

J41B-16/25K

|

Malleable Iron

|

Carbon Steel

|

PTFE (Polytetrafluoroethylene)

|

Babbitt Alloy

|

Asbestos Rubber Sheet

|

High-Quality Carbon Steel

|

3.4 Operating Precautions

-

Ammonia globe valves come in various specifications based on application requirements. The maximum inlet pressure is mostly consistent with the nominal pressure, and the minimum inlet pressure should not be less than 2.5 times the outlet pressure. There are multiple outlet pressure specifications, with the maximum outlet pressure matching the nominal pressure.

-

When installing the ammonia globe valve, ensure its connection specification matches the connector of the application system. Before installation, high-pressure gas can be used to blow off dust. If necessary, gaskets made of materials such as PTFE can be used.

-

The ammonia globe valve must be strictly prohibited from contacting grease to avoid fire accidents.

-

When stopping work, release the residual gas in the pressure reducing valve, then loosen the adjusting screw to prevent the elastic element from being deformed due to long-term pressure.

-

The ammonia globe valve should be protected from impact and vibration, and should not come into contact with corrosive substances.

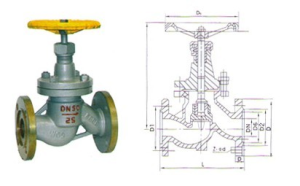

4. The Main Shape and Connection Size

Unit: mm

4.1 Dimensions

|

Nominal Diameter DN (mm)

|

L

|

D

|

D1

|

D2

|

D6

|

b

|

f

|

f2

|

z-d

|

H

|

D0

|

|---|---|---|---|---|---|---|---|---|---|---|---|

|

10

|

130

|

90

|

60

|

40

|

35

|

14

|

2

|

4

|

4-14

|

196

|

120

|

|

15

|

130

|

95

|

65

|

45

|

40

|

14

|

2

|

4

|

4-14

|

196

|

120

|

|

20

|

150

|

105

|

75

|

55

|

51

|

16

|

2

|

4

|

4-14

|

196

|

140

|

|

25

|

160

|

115

|

85

|

65

|

58

|

16

|

2

|

4

|

4-14

|

204

|

160

|

|

32

|

180

|

135

|

100

|

78

|

66

|

18

|

2

|

4

|

4-18

|

208

|

160

|

|

40

|

200

|

145

|

110

|

85

|

76

|

18

|

3

|

4

|

4-18

|

248

|

200

|

|

50

|

230

|

160

|

125

|

100

|

88

|

20

|

3

|

4

|

4-18

|

248

|

200

|

|

65

|

290

|

180

|

145

|

125

|

110

|

22

|

3

|

4

|

8-18

|

321

|

240

|

|

80

|

310

|

195

|

160

|

135

|

121

|

24

|

3

|

4

|

8-18

|

325

|

240

|

|

100

|

350

|

215

|

180

|

155

|

150

|

24

|

3

|

4.5

|

8-18

|

371

|

280

|

|

125

|

400

|

245

|

210

|

185

|

176

|

26

|

3

|

4.5

|

8-18

|

400

|

320

|

|

150

|

480

|

280

|

240

|

210

|

204

|

26

|

3

|

4.5

|

8-23

|

432

|

320

|

|

200

|

600

|

335

|

295

|

265

|

260

|

30

|

3

|

4.5

|

12-23

|

654

|

400

|

|

250

|

650

|

405

|

335

|

320

|

313

|

32

|

3

|

4.5

|

12-25

|

745

|

500

|

|

300

|

700

|

460

|

410

|

375

|

364

|

34

|

3

|

4.5

|

12-25

|

852

|

600

|

4.2 Dimensions

|

Nominal Diameter DN (mm)

|

L

|

D

|

D1

|

D2

|

D6

|

b

|

f

|

f2

|

z-d

|

H

|

D0

|

|---|---|---|---|---|---|---|---|---|---|---|---|

|

10

|

130

|

90

|

60

|

40

|

35

|

16

|

2

|

4

|

4-14

|

196

|

120

|

|

15

|

130

|

95

|

65

|

45

|

40

|

16

|

2

|

4

|

4-14

|

196

|

120

|

|

20

|

150

|

105

|

75

|

55

|

51

|

16

|

2

|

4

|

4-14

|

196

|

120

|

|

25

|

160

|

115

|

85

|

65

|

58

|

18

|

2

|

4

|

4-14

|

201

|

120

|

|

32

|

180

|

135

|

100

|

78

|

66

|

18

|

2

|

4

|

4-18

|

208

|

120

|

|

40

|

200

|

145

|

110

|

85

|

76

|

20

|

2

|

4

|

4-18

|

248

|

160

|

|

50

|

230

|

160

|

125

|

100

|

88

|

20

|

3

|

4

|

4-18

|

248

|

160

|

|

65

|

290

|

180

|

145

|

125

|

110

|

22

|

3

|

4

|

8-18

|

321

|

240

|

|

80

|

310

|

195

|

160

|

135

|

121

|

24

|

3

|

4

|

8-18

|

325

|

240

|

|

100

|

350

|

230

|

190

|

160

|

150

|

24

|

3

|

4.5

|

8-23

|

371

|

280

|

|

125

|

400

|

270

|

220

|

188

|

176

|

30

|

3

|

4.5

|

8-25

|

400

|

320

|

|

150

|

480

|

300

|

250

|

218

|

204

|

30

|

3

|

4.5

|

8-25

|

432

|

320

|

|

200

|

600

|

360

|

310

|

278

|

260

|

34

|

3

|

4.5

|

12-30

|

654

|

400

|