一.Product Introduction

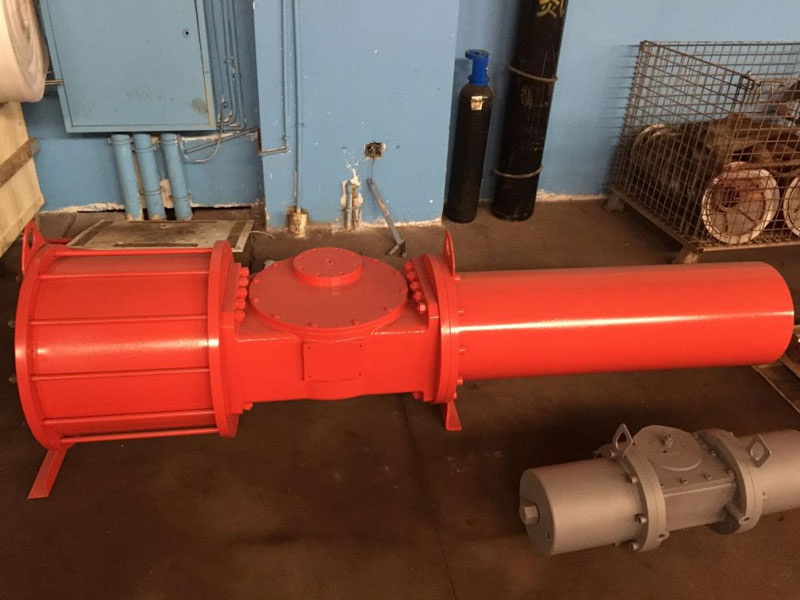

Valve actuators are pivotal components in industrial automation and process control systems, serving as the “driving force” behind the operation of valves (such as ball valves, butterfly valves, gate valves, and globe valves). They convert energy (pneumatic, electric, hydraulic, or manual) into mechanical motion to control the opening, closing, or modulation of valves. This ensures precise fluid (liquid, gas) flow regulation in critical industries including oil and gas, chemical processing, water treatment, power generation, and pharmaceuticals. Actuators for valves not only enhance operational efficiency but also enable remote control, automation, and safety interlocks, making them indispensable for both routine and emergency process management.

二.Product Features

1. Diverse Energy Sources & Types

- Pneumatic Actuators (e.g., the Festo DFPD series): Rely on compressed air to generate torque or linear force. They offer fast response times, high durability, and intrinsic safety in explosive environments.

- Electric Actuators: Use electric motors to drive valves. They provide precise control, easy integration with digital control systems, and are ideal for applications requiring multi-turn or modulated operation.

- Hydraulic Actuators: Leverage hydraulic fluid for extremely high force/torque output, suitable for large-diameter valves or high-pressure systems (e.g., in offshore oil platforms).

- Manual Actuators: Depend on human force (handwheels, levers) and serve as backup or for small-scale, low-frequency operations.

2. Precision & Control

- Enable accurate positioning (e.g., modulating electric actuators can control valve opening from 0% to 100% with fine increments).

- Support both on/off (full open/close) and throttling (flow regulation) applications.

3. Safety & Reliability

- Equipped with fail-safe mechanisms (e.g., spring-return in pneumatic actuators to close/open valves during air supply failure).

- Built with corrosion-resistant materials (stainless steel, coated alloys) to withstand harsh industrial environments (chemical exposure, extreme temperatures).

4. Integration & Compatibility

- Compatible with various valve types (quarter-turn, multi-turn) and sizes (from small DN10 valves to large DN1000+ valves).

- Support industry-standard communication protocols (Modbus, HART) for seamless integration with PLCs, SCADA systems, and IoT platforms.

三.Technical Data (General Specifications, Varies by Type/Model)

1. Pneumatic Actuators (Example: Festo DFPD Series)

- Torque Range: Typically 5–1000 Nm (varies by model, e.g., DFPD-20 offers 20.1 Nm).

- Swivel Angle: 90° (standard for quarter-turn valves), with optional adjustability in some models.

- Pneumatic Connection: G1/8, G1/4, etc. (e.g., DFPD-20 uses G1/8).

- Operating Pressure Range: 2–8 bar (compressed air).

- Temperature Range: -20°C to +80°C (standard), extended ranges available for extreme conditions.

- Mounting Standards: Conform to ISO 5211 (flange hole patterns like F03, F05).

2. Electric Actuators

- Motor Power: 0.1–10 kW (based on valve size and torque requirement).

- Control Precision: ±0.5–2% of full stroke.

- Voltage: 24 VDC, 110 VAC, 230 VAC, 380 VAC, etc.

- Protection Class: IP66/IP68 (dust-tight, waterproof for outdoor or harsh environments).

- Output Speed: 0.1–60 rpm (varies by model and application).

3. Hydraulic Actuators

- Torque/Force Range: Up to several thousand Nm or tons (for large valves).

- Operating Pressure: 10–400 bar (hydraulic fluid pressure).

- Response Time: Milliseconds to seconds (depending on system design).

4. Manual Actuators

- Torque Rating: Typically up to 1000 Nm (handwheel-operated), with gear reduction for higher torque needs.

- Material: Cast iron, stainless steel, or engineering plastics.

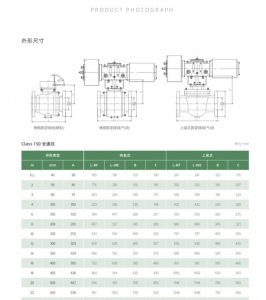

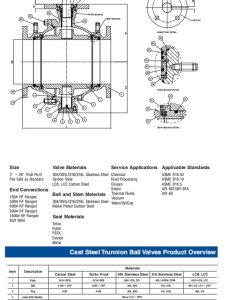

四.The main shape and connection size