I. Product Introduction

Pneumatic Control Valves are core executive components in industrial automation control systems. As a critical device for process regulation, Pneumatic Control Valves adopt compressed air as the power source to precisely adjust the flow rate, pressure, temperature, and liquid level of fluid media (such as gas, liquid, and steam) in pipelines or equipment. Each Pneumatic Control Valve consists of two essential parts: the actuator and the valve body. The actuator of the Pneumatic Control Valve converts pneumatic signals into mechanical motion (either linear or rotary), while the valve body of the Pneumatic Control Valve regulates the flow area between the internal valve core and valve seat—working in tandem to achieve accurate control of the media by the Pneumatic Control Valve.

Pneumatic Control Valves are widely applied across industries including petroleum, chemical engineering, electric power, water treatment, food, and pharmaceuticals. In these fields, Pneumatic Control Valves play an irreplaceable role in stabilizing production processes, improving product quality, and reducing system pressure. Compared with electric control valves, Pneumatic Control Valves offer distinct advantages such as explosion resistance, high pressure tolerance, fast response speed, and strong adaptability to pneumatic environments—making Pneumatic Control Valves an indispensable core device in industrial process control.

II. Product Features

1. High Safety and Excellent Dynamic Performance

Pneumatic Control Valves use compressed air as the sole power source, ensuring no electric sparks are generated during operation. This design allows Pneumatic Control Valves to fully meet the explosion-proof requirements of hazardous areas (e.g., petroleum and chemical industries) and comply with strict explosion-proof ratings such as Ex d IIB T4 or Ex ia IIC T6. For industries with high safety risks, Pneumatic Control Valves provide reliable operation guarantees through their inherent safety design.

2. Fast Response and Precise Control Capability

The pneumatic actuator of Pneumatic Control Valves features extremely short action time, with the opening/closing response speed of Pneumatic Control Valves ranging from 0.1 to 0.5 seconds (adjustable according to specific models). When equipped with matching accessories such as intelligent electro-pneumatic positioners, Pneumatic Control Valves can achieve precise positioning of critical valve cores. The control accuracy of Pneumatic Control Valves can reach ±0.5% of the full stroke, effectively ensuring the stability of process parameter control in various industrial scenarios.

3. Strong Environmental Adaptability

The valve body of Pneumatic Control Valves is manufactured from high-quality materials including 304 stainless steel, 316L stainless steel, and Hastelloy. This premium material selection endows Pneumatic Control Valves with excellent corrosion resistance and wear resistance, enabling Pneumatic Control Valves to adapt to harsh working conditions involving various hazardous media such as strong acids, strong alkalis, and high-temperature steam. Additionally, Pneumatic Control Valves are fitted with waterproof, anti-corrosion, and anti-aging seals, allowing Pneumatic Control Valves to operate normally in a wide temperature range of -40℃ to +120℃ (high-temperature and low-temperature specialized models of Pneumatic Control Valves can cover an extended range of approximately -60℃ to +200℃).

4. Simple Structure and High Reliability

Pneumatic Control Valves are designed with a streamlined structure, featuring few moving parts—greatly reducing the failure rate of Pneumatic Control Valves. Key components of Pneumatic Control Valves, such as valve cores, valve seats, and seals, undergo rigorous performance testing and aging treatment before assembly, ensuring that the service life of Pneumatic Control Valves exceeds 100,000 cycles. Moreover, Pneumatic Control Valves are easy to maintain: daily maintenance tasks for Pneumatic Control Valves, such as seal replacement, can be completed quickly on-site without complex disassembly.

5. Good Compatibility and Versatile Application

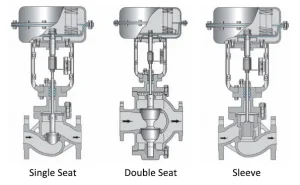

Pneumatic Control Valves support multiple signal input modes (e.g., 4-20mA current signal, 0-10V voltage signal), enabling Pneumatic Control Valves to seamlessly integrate with various industrial control systems (e.g., DCS, PLC). To meet diverse process requirements, Pneumatic Control Valves are available in multiple structural forms (e.g., Pneumatic Control Globe Valves, Pneumatic Control Gate Valves, Pneumatic Control Butterfly Valves, Pneumatic Control Ball Valves) and different flow characteristics (linear, equal percentage, quick opening). This versatility ensures that Pneumatic Control Valves can adapt to the control needs of various process scenarios in different industries.

III. Technical Data

Technical Parameters

| Specification | Description |

|---|---|

| Valve Size Range | DN15-DN300 (1/2″-12″) |

| Nominal Pressure (PN) | PN16, PN25, PN40, PN64, PN100; ANSI Class 150, 300, 600 |

| Medium Temperature Range | Standard: -40℃ to +120℃; High-temperature: -20℃ to +200℃; Low-temperature: -60℃ to +80℃ |

| Medium | Gas (natural gas, air, nitrogen, etc.), Liquid (water, oil, chemical solutions, etc.), Steam |

| Actuator Power Source | Compressed air, pressure range: 0.4-0.8MPa (60-120PSI) |

| Control Signal Input | 4-20mA DC current signal (standard); 0-10V DC voltage signal (optional) |

| Position Feedback Signal | 4-20mA DC current signal (standard); HART digital signal (optional) |

| Control Accuracy | ±0.5% of stroke (with intelligent positioner) |

| Response Time | 0.1-0.5 seconds (depends on valve size and actuator model) |

| Valve Body Material | 304 stainless steel (standard), 316L stainless steel, Hastelloy, carbon steel (optional) |

| Valve Core/Seat Material | 304 stainless steel, 316L stainless steel, Stellite (wear and corrosion resistant) |

| Seal Material | PTFE (standard), FKM, EPDM, silicone (optional, based on medium temperature and corrosion requirements) |

| Explosion-Proof Rating | Ex d IIB T4, Ex ia IIC T6 (optional) |

| Protection Rating | IP65, IP67 (optional) |

| Flow Characteristics | Linear, equal percentage, quick opening (optional) |

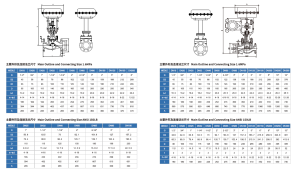

Ⅳ.The main shape and connection size