I. Product Introduction

The steam control valve is a precision fluid control component specifically designed for steam medium systems, widely applied in industries such as power generation, petrochemical, food and beverage processing, textile, and HVAC. Its core function is to automatically adjust the flow rate, pressure, or temperature of steam according to the signals from the control system (e.g., PLC, DCS), thereby ensuring the stability of the production process and the reliability of equipment operation.

Different from ordinary stop valves, the steam control valve focuses on “adjustability” and “precision”. It can achieve stepless regulation of steam flow within a specific range, rather than just on-off control. This characteristic makes it an indispensable core component in automatic control loops. It can effectively cope with the harsh working conditions of steam, such as high temperature, high pressure, and potential cavitation or erosion, and maintain stable performance for a long time.

The product adopts a modular design, which is convenient for maintenance and replacement of internal components (such as valve cores, seats, and sealing rings). At the same time, it can be matched with different types of actuators (pneumatic, electric, hydraulic) according to actual application scenarios to meet the control needs of different automation levels.

II. Product Features

1. Excellent High-Temperature and High-Pressure Resistance

The valve body and internal key components are made of high-quality alloy materials (such as 316L stainless steel, WCB carbon steel, or Inconel alloy). After special heat treatment, they have excellent high-temperature strength and corrosion resistance. They can work stably in the temperature range of -20℃ to 450℃ (customizable up to 600℃ for high-temperature models) and the pressure range of PN16 to PN400, effectively resisting the erosion and oxidation of high-temperature steam.

2. High Precision Regulation Performance

Equipped with a high-sensitivity valve core (such as V-type, parabolic, or equal percentage flow characteristic) and a high-response actuator, the regulation accuracy can reach ±0.5% of the full scale. The flow characteristic curve is smooth, which can realize linear or equal percentage flow regulation according to the process requirements, avoiding sudden changes in steam flow and ensuring the stability of the controlled parameter (such as temperature, pressure) of the system.

3. Strong Anti-Cavitation and Anti-Erosion Capabilities

Aiming at the problem of cavitation and erosion easily caused by steam pressure changes, the product adopts a multi-stage throttling valve core structure or a streamlined flow channel design. This can reduce the pressure drop gradient of steam in the valve, avoid the generation of vapor bubbles and the impact of cavitation on the valve core and seat, and extend the service life of the product by more than 30% compared with ordinary control valves.

4. Reliable Sealing Performance

The sealing pair adopts hard sealing (such as stellite alloy surfacing) or soft sealing (such as PTFE reinforced with graphite) according to different working conditions. The hard sealing structure can withstand high temperature and high pressure, with a sealing grade of Class V; the soft sealing structure can achieve zero leakage under low and medium pressure conditions, meeting the strict environmental protection and energy-saving requirements of the industry.

5. Convenient Installation and Maintenance

The valve adopts a top-entry or side-entry structure, which allows the internal components to be inspected and replaced without removing the valve body from the pipeline, greatly reducing the maintenance time and labor cost. The actuator interface is in line with international standards (such as ISO5211), which is convenient for matching with actuators of different brands and types. At the same time, the product is equipped with a positioner and a limit switch (optional), which can realize real-time monitoring and feedback of the valve opening.

III. Technical Data

|

Technical Parameter

|

Specification

|

Remarks

|

|---|---|---|

|

Valve Type

|

Globe Valve, Angle Valve, Butterfly Valve

|

Customizable according to flow requirements

|

|

Nominal Diameter (DN)

|

DN15 – DN300

|

DN350 – DN600 available on request

|

|

Nominal Pressure (PN)

|

PN16, PN25, PN40, PN64, PN100, PN160, PN250, PN400

|

Corresponding Class rating: Class150, Class300, Class600, etc.

|

|

Medium Temperature Range

|

-20℃ – 450℃

|

High-temperature model: up to 600℃ (alloy material)

|

|

Flow Characteristic

|

Linear, Equal Percentage, Quick Opening

|

V-type valve core for quick opening

|

|

Regulation Accuracy

|

±0.5% of full scale

|

Under rated working conditions

|

|

Leakage Grade

|

Class V (hard sealing), Class VI (soft sealing)

|

In accordance with GB/T 4213-2008

|

|

Valve Body Material

|

WCB, 304SS, 316LSS, Inconel 625

|

Selected according to medium corrosion

|

|

Valve Core/Seat Material

|

316LSS + Stellite alloy surfacing

|

High wear resistance

|

|

Actuator Type

|

Pneumatic diaphragm actuator, Electric actuator

|

Pneumatic type with positioner

|

|

Input Signal

|

Pneumatic: 0.02 – 0.1MPa; Electric: 4 – 20mA DC

|

Standard signal, customizable

|

|

Response Time

|

≤0.5s (pneumatic); ≤1s (electric)

|

From 0 to 100% opening

|

|

Connection Type

|

Flanged (GB/T 9113), Threaded (NPT/G), Welded

|

Flanged connection as standard

|

|

Working Environment Temperature

|

-40℃ – 80℃

|

Low-temperature protection available on request

|

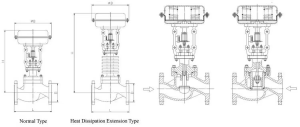

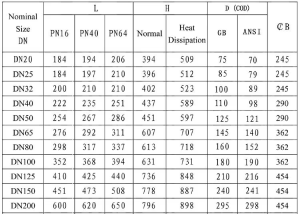

Ⅳ.The main shape and connection size