一、Product Introduction

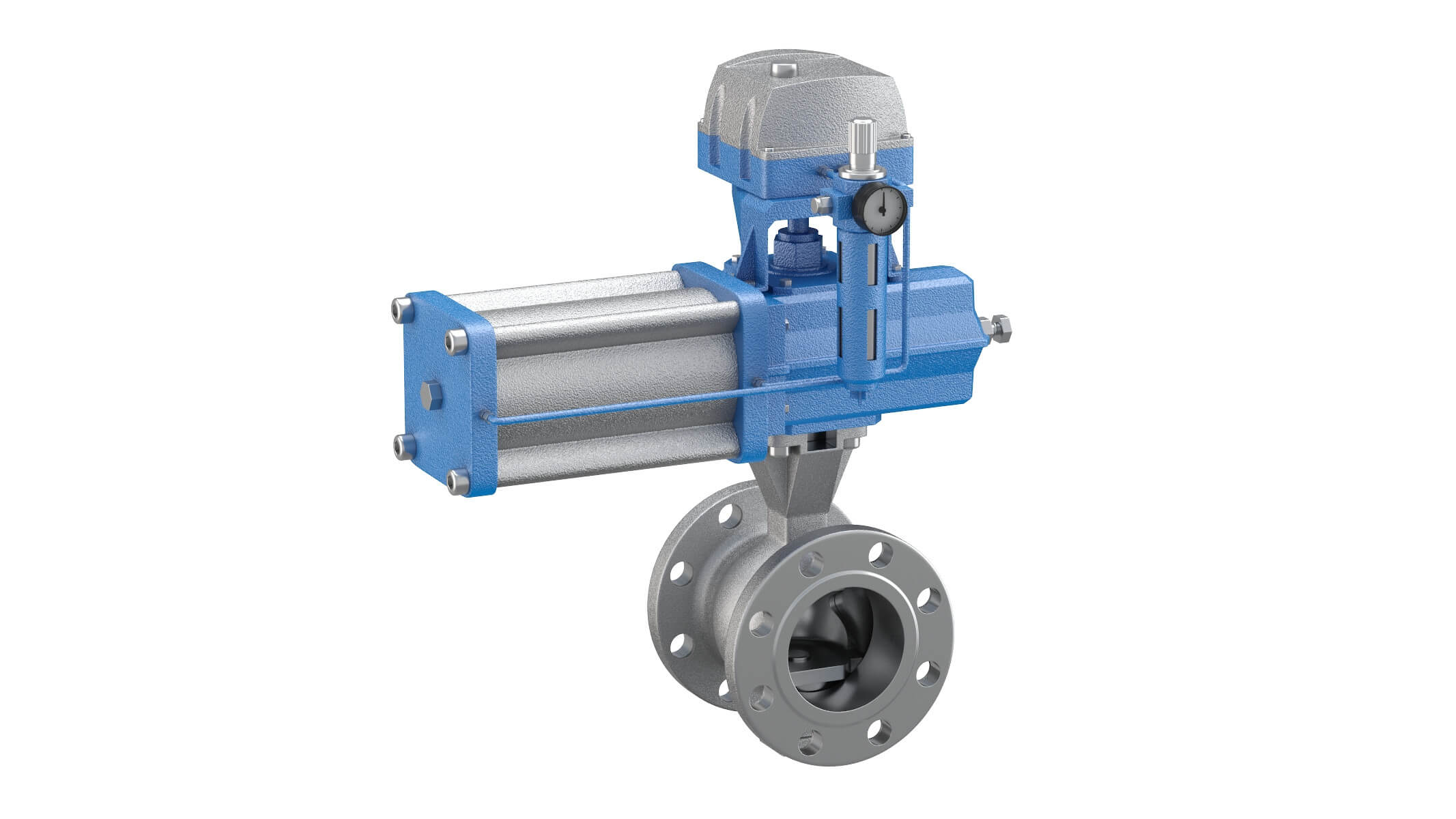

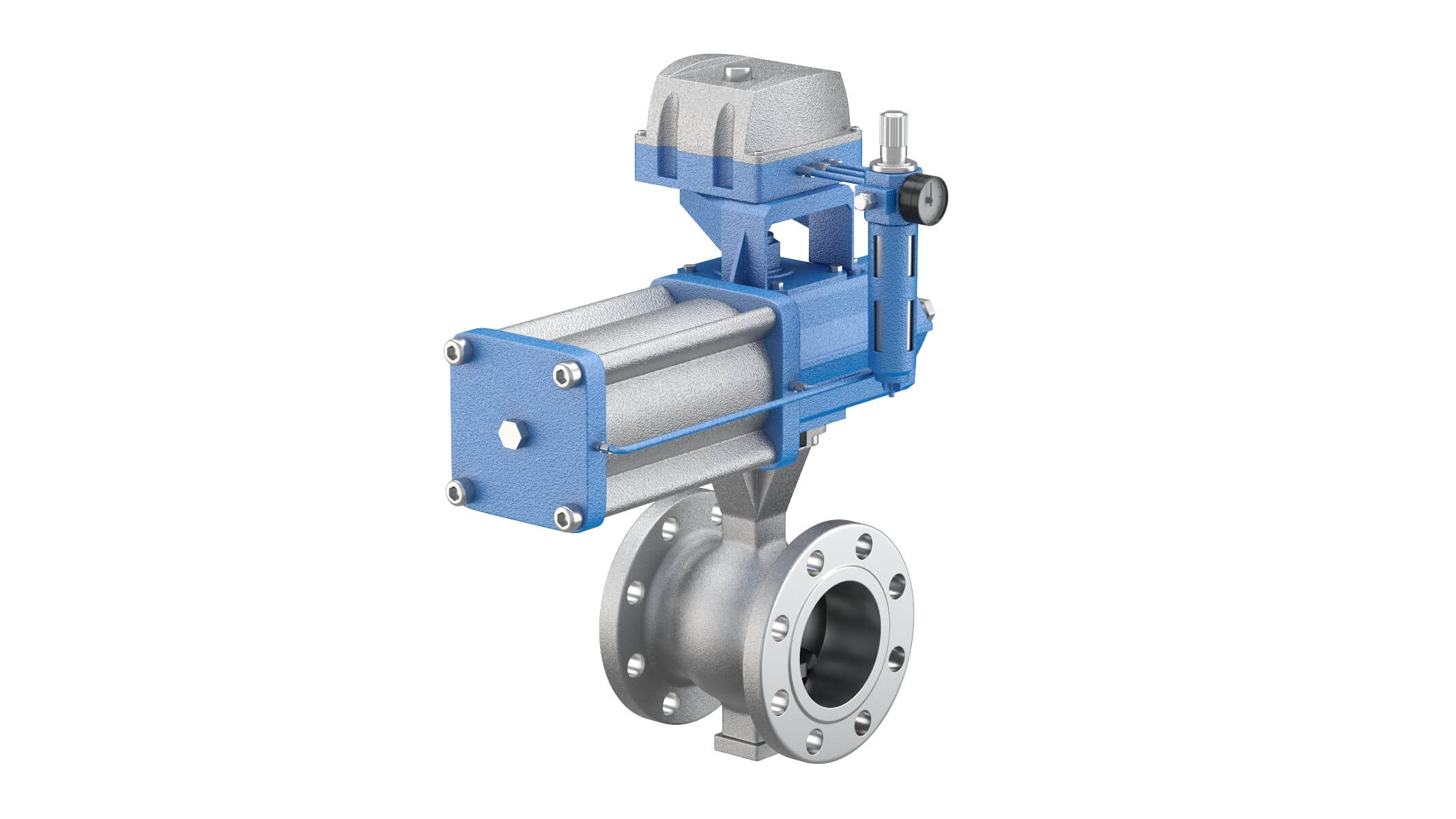

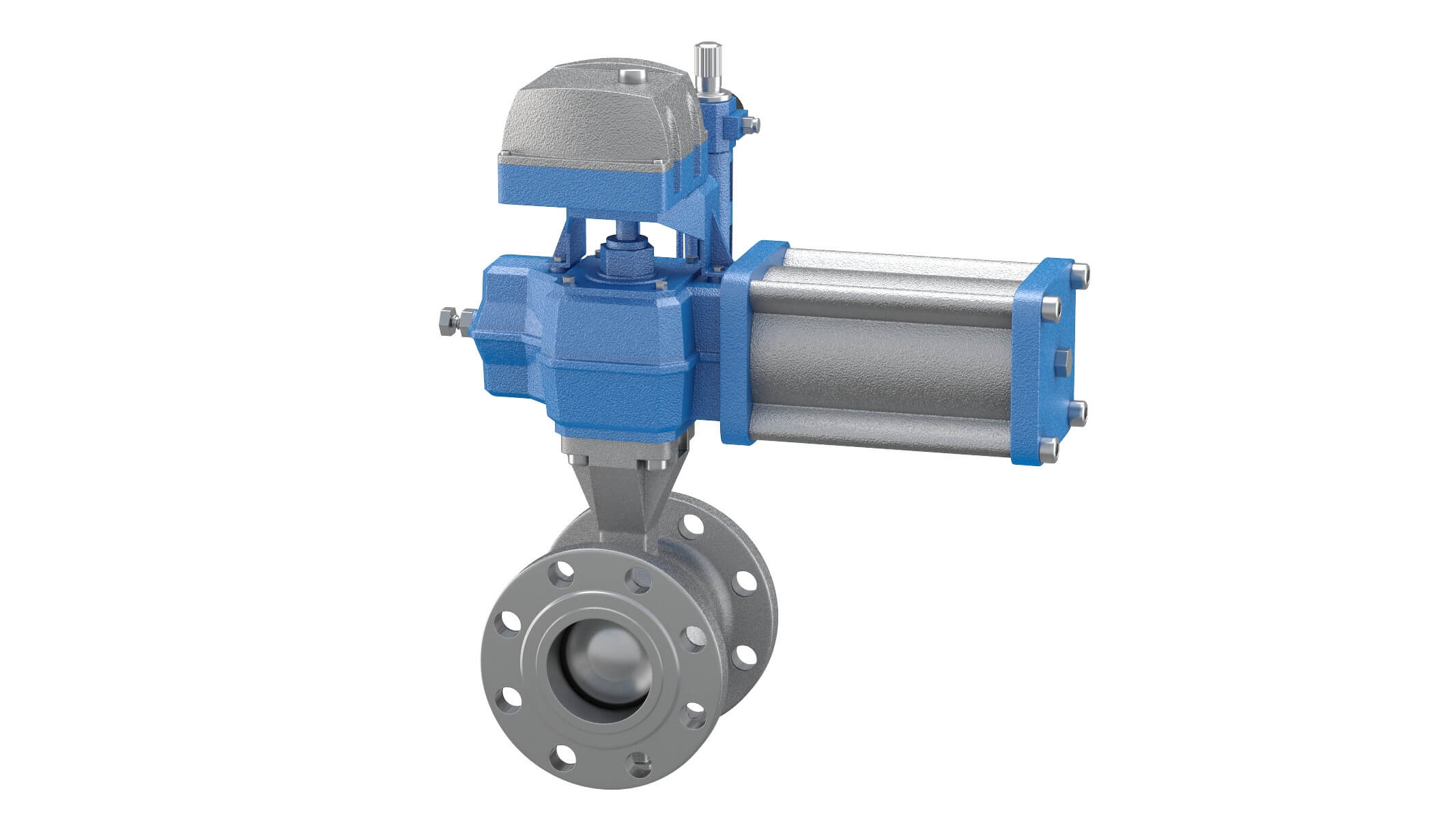

A segmented ball valve (also known as a V-notch ball valve) is a high-performance control valve widely used in industrial fluid control systems. Its core component is a segmented (V-shaped notch) ball core that rotates to adjust the flow area, achieving precise regulation of media such as liquids, gases, and slurries. Compared with full-port ball valves, it features excellent throttling and control performance, making it suitable for scenarios requiring high-precision flow control, pressure regulation, and on-off operation in large-scale projects (e.g., water conservancy, petrochemical, and infrastructure projects undertaken by China Railway Project Departments). The valve is compatible with various actuation methods (manual, pneumatic, electric) and is designed for reliability, corrosion resistance, and long service life in harsh working conditions.

二、Product Features

| Feature Category | Key Advantages |

|---|---|

| Flow Control Precision | V-shaped notch design enables linear or equal percentage flow characteristics, ensuring high-precision regulation (control accuracy up to ±0.5%). |

| Throttling Performance | Segmented ball core forms a shear effect with the seat, effectively preventing clogging by solid particles (suitable for slurry or viscous media). |

| Seal Reliability | Metal-to-metal or soft seal options (PTFE, RTFE) provide bubble-tight sealing; fire-safe design meets API 607/ISO 10497 standards. |

| Structural Durability | Robust body construction (cast steel, stainless steel) resists high pressure (up to Class 2500) and temperature (-29℃ to 538℃). |

| Versatile Actuation | Compatible with pneumatic/electric actuators for automatic control; supports Modbus, HART communication protocols for smart integration. |

| Easy Maintenance | Split-body or top-entry design allows on-site maintenance without removing the valve from the pipeline, reducing downtime. |

三、Technical Data

| Parameter | Specification |

|---|---|

| Valve Type | Segmented ball valve (V-notch), 2-way/3-way options |

| Nominal Diameter (DN) | DN15 ~ DN600 (1/2″ ~ 24″) |

| Nominal Pressure (PN) | PN16 ~ PN420 (Class 150 ~ Class 2500) |

| Body Material | Carbon steel (WCB), stainless steel (304/316L), alloy steel (A182 F11/F22) |

| Ball/Seat Material | Ball: 304/316L, Stellite-faced; Seat: PTFE, RTFE, metal-to-metal |

| Operating Temperature | -29℃ ~ 538℃ (-20℉ ~ 1000℉) |

| Flow Characteristic | Linear, equal percentage, quick-opening (customizable) |

| Leakage Class | ANSI/FCI 70-2 Class IV (soft seal), Class V (metal seal) |

| Actuation Method | Manual (handwheel), pneumatic (double-acting/spring-return), electric |

| Connection Type | Flanged (ANSI B16.5/EN 1092), threaded (NPT/BSP), welded (SW/BW) |

| Standards Compliance | API 6D, API 607, ISO 10497, ANSI B16.34, EN 12516 |

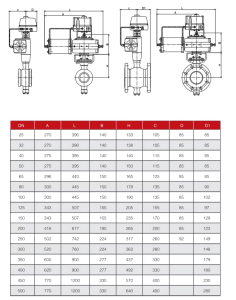

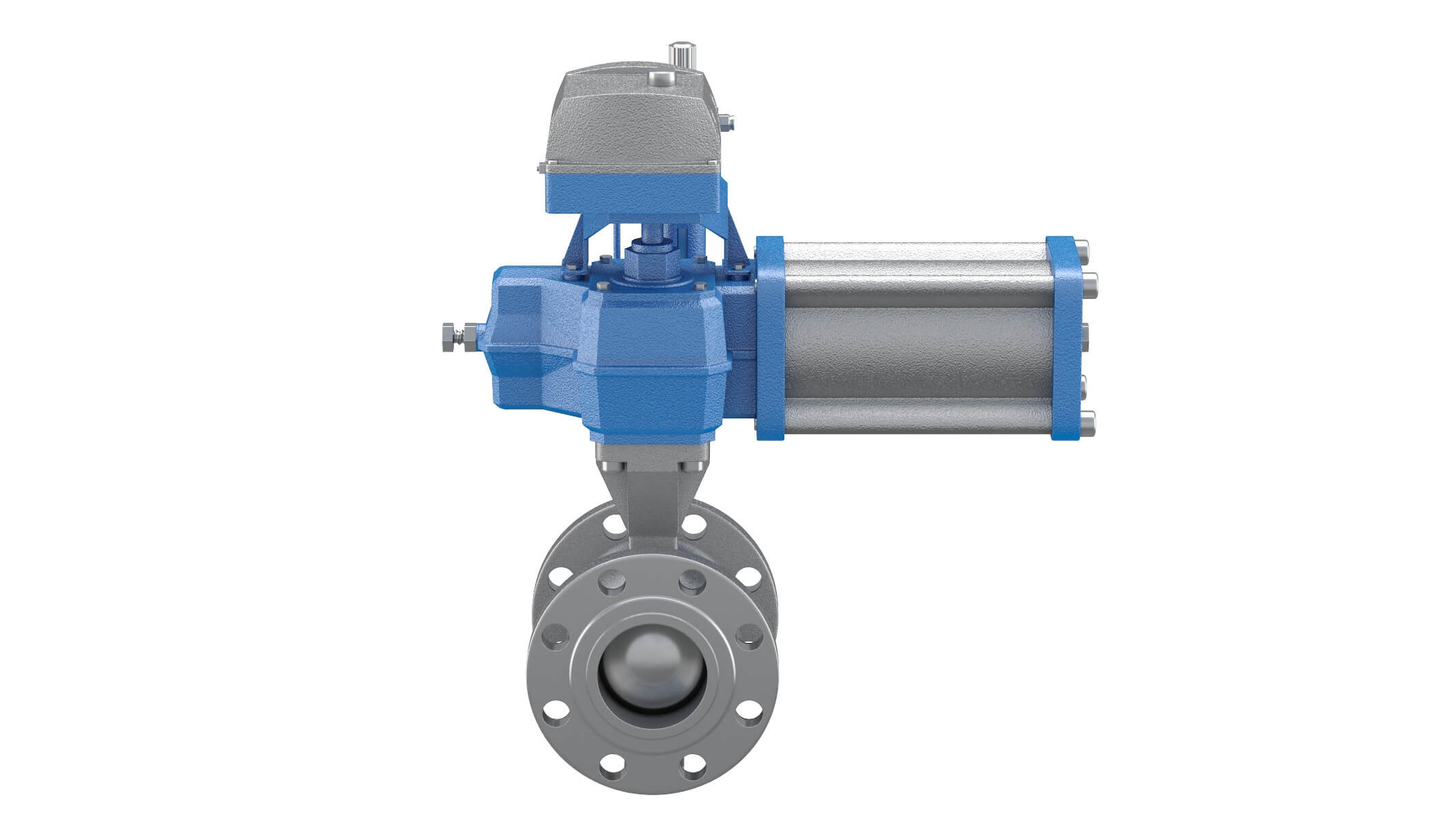

四.The main shape and connection size