1. Product Introduction

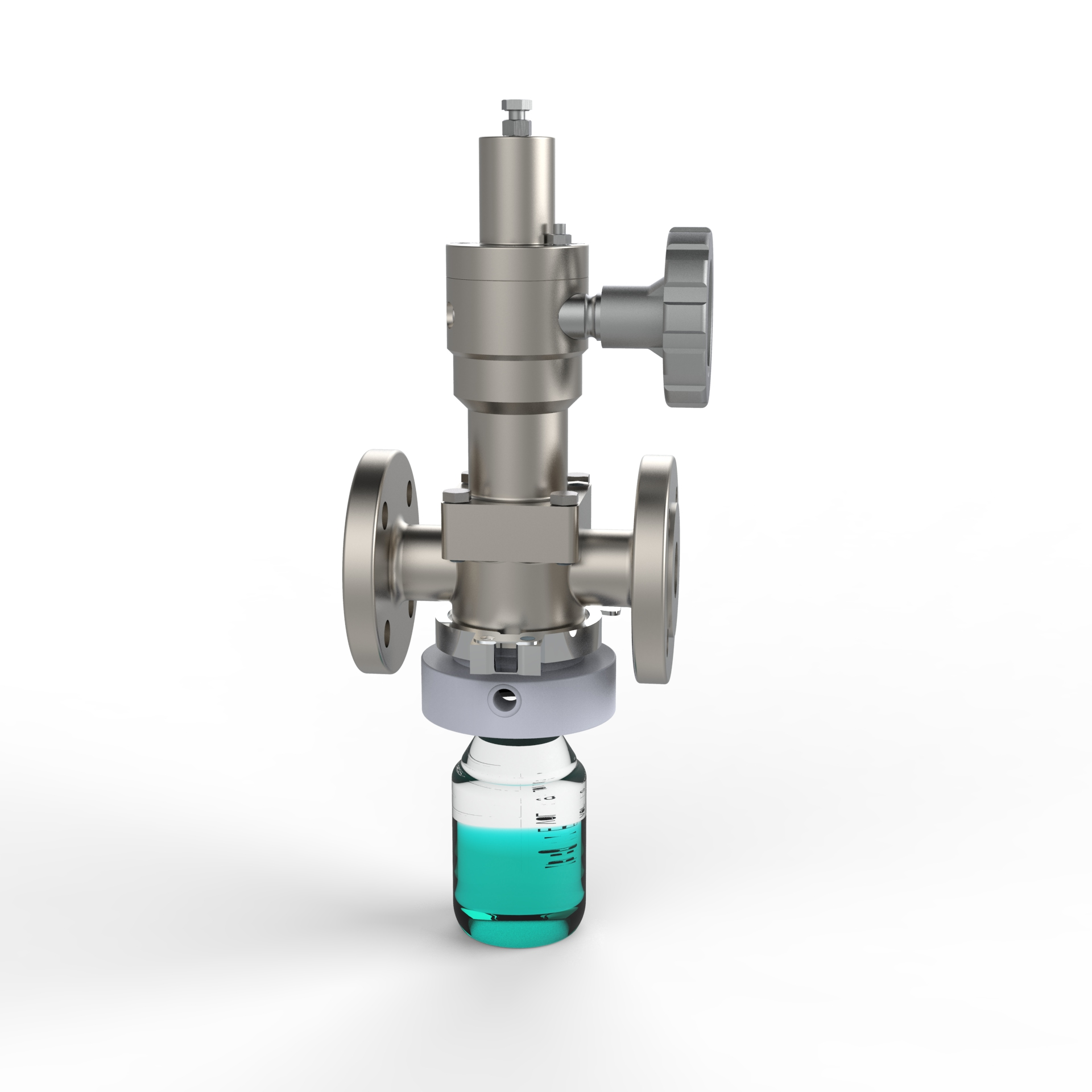

A liquid sampling valve is a specialized fluid control component designed to safely, accurately, and reproducibly extract representative samples from liquid storage tanks, pipelines, reactors, or other process systems. It serves as a critical interface between industrial processes (e.g., chemical, pharmaceutical, food & beverage, petroleum) and quality control (QC) testing, ensuring that sampled liquids reflect the actual composition, purity, or property of the bulk fluid—without causing process disruption, contamination, or safety hazards.

Unlike general valves, its core function focuses on “sampling representativeness” (avoiding dead zones where stale fluid accumulates) and “operational safety” (preventing leakage of hazardous or sterile liquids). It is widely used in scenarios requiring strict quality monitoring, such as pharmaceutical API production (complying with GMP standards), edible oil refining (testing for impurities), and chemical reagent synthesis (tracking reaction progress).

2. Product Features

-

Representative Sampling DesignIntegrates anti-dead-volume structures (e.g., smooth internal cavities, no stagnant corners) to eliminate residual fluid from previous samples, ensuring each extraction matches the bulk liquid’s properties. For viscous liquids, optional tapered or streamlined flow channels reduce sample retention; for heterogeneous liquids, some models support in-line mixing pre-sampling.

-

High Safety & ReliabilityAdopts leak-proof sealing systems (e.g., PTFE, Viton, or metal-to-metal seals) to prevent volatile, corrosive, or toxic liquids from escaping. Explosion-proof versions (certified to ATEX, IECEx) are available for flammable liquid applications; sterile models (with electropolished 316L stainless steel surfaces and sanitizable connections) meet pharmaceutical and food industry requirements.

-

Easy Operation & MaintenanceDesigned with user-friendly interfaces—manual models feature ergonomic handles (with adjustable sampling volume stops), while automatic versions support PLC control for timed/remote sampling. Modular structures allow quick disassembly of sampling heads or seals without full valve removal; self-cleaning options (e.g., CIP/SIP compatibility) reduce manual cleaning workload.

-

Corrosion & Wear ResistanceConstructed from high-performance materials: 316L stainless steel (for general corrosive liquids), Hastelloy (for strong acids like sulfuric acid), or PTFE-lined bodies (for aggressive chemicals). Internal components (e.g., valves cores) use hardened alloys to resist abrasion from particulate-containing liquids.

-

Wide Process AdaptabilitySuitable for diverse working conditions: low-temperature models (-40℃ to 60℃) for refrigerated liquids, high-temperature versions (up to 300℃) for thermal fluids, and high-pressure designs (up to 40MPa) for pipeline sampling in oil & gas industries.

3. Technical Data

| Parameter | Typical Specification | Notes |

|---|---|---|

| Material | Body: 316L SS/Hastelloy/PTFE-lined; Seal: PTFE/Viton | Custom materials available for special media |

| Working Pressure | 0.1MPa ~ 40MPa | High-pressure models (≥20MPa) use forged bodies |

| Working Temperature | -40℃ ~ 300℃ | Cryogenic versions down to -196℃ (for LN2-cooled liquids) |

| Sampling Volume Range | 0.5mL ~ 500mL | Adjustable via valve core stroke or dosing chambers |

| Connection Type | Threaded (NPT/G), Flanged (ANSI/PN), Sanitary (Tri-Clamp) | Sanitary connections for food/pharmacy |

| Sealing Performance | Leak rate ≤ 1×10⁻⁷ Pa·m³/s | Tested with helium (for high-purity applications) |

| Operating Mode | Manual, Pneumatic, Electric (24V DC/220V AC) | Automatic models support Modbus communication |

| Applicable Fluid Viscosity | 0.1 mPa·s ~ 10,000 mPa·s | Viscous fluids require heated or enlarged channels |

| Certifications | ISO 9001, CE, FDA, ATEX/IECEx | Certifications vary by industry and region |