一.Product Introduction

The Pneumatic carbon steel ball valve is an industrial fluid control device integrating pneumatic automatic drive and manual emergency operation. Its valve body is mainly made of carbon steel (e.g., WCB), which balances structural strength and cost-effectiveness.

The valve is driven by a pneumatic actuator to realize rapid on-off control of media (suitable for automatic process systems), and is equipped with a manual operating wheel — which can be used for emergency operation when the air source fails, ensuring continuous pipeline operation. It is widely applied in pipeline systems of petroleum, chemical, power, and municipal engineering to control the transportation of non-strongly corrosive media (such as water, oil, natural gas, and general industrial fluids).

二.Product Features

- Dual operation mode: Pneumatic drive enables fast response (opening/closing in seconds for small specifications), while the built-in manual wheel provides emergency operation support for air source failures, enhancing operational reliability.

- Cost-effective carbon steel body: Adopts WCB carbon steel as the main valve material, featuring high mechanical strength, good processability, and suitable cost — ideal for conventional industrial medium control scenarios.

- Reliable sealing performance: Equipped with soft sealing (e.g., PTFE) or hard sealing structures, it ensures low leakage rate (conforming to GB/T13927 standards) and stable operation under rated working conditions.

- Compact & easy installation: Flange connection design, compact overall structure, and good compatibility with standard industrial pipelines, reducing on-site installation and layout difficulty.

- Flexible accessory matching: Can be equipped with solenoid valves, limit switches, air source treatment triplets, etc., to realize remote control, state feedback, and air source purification, adapting to intelligent system integration.

三.Technical data

1. Performance Specifications

| Item | Parameter |

|---|---|

| Typical Model | Q641F-16C (soft seal), Q641Y-16C (hard seal) |

| Nominal Diameter | DN15 – DN200 mm (1/2″ – 8″) |

| Pressure Rating | PN1.6 MPa, PN2.5 MPa, PN4.0 MPa, PN6.4 MPa (Class 150 LB) |

| Working Temperature | -29℃ ~ 180℃ (determined by sealing material and carbon steel performance) |

| Applicable Medium | Water, oil, natural gas, general industrial fluids (non-strongly corrosive) |

| Drive Mode | Pneumatic actuator (double-acting/single-acting) + manual operating wheel |

| Connection Method | Flange (conforming to GB/T9113 standard) |

2. Executive Standards

| Item | Corresponding Standard |

|---|---|

| Design Basis | GB/T 12237 (Carbon steel ball valve design standard) |

| Structure Length | GB/T 12221 (Valve structure length standard) |

| Flange Connection | GB/T 9113 (Steel pipe flange standard) |

| Testing & Inspection | GB/T 13927 (Valve pressure test standard), JB/T 7902 (Valve inspection standard) |

3. Main Parts & Materials (Carbon Steel Series)

| Serial No. | Part Name | Material Quality |

|---|---|---|

| 1 | Valve Body | Carbon steel (WCB) |

| 2 | Ball | Carbon steel (1Cr13) |

| 3 | Valve Stem | Carbon steel (2Cr13) |

| 4 | Valve Seat | PTFE (soft seal) / Stellite alloy (hard seal) |

| 5 | Manual Operating Wheel | Cast iron (HT200) |

| 6 | Pneumatic Actuator Shell | Aluminum alloy (ADC12) |

| 7 | Sealing Ring | Fluororubber (FKM) |

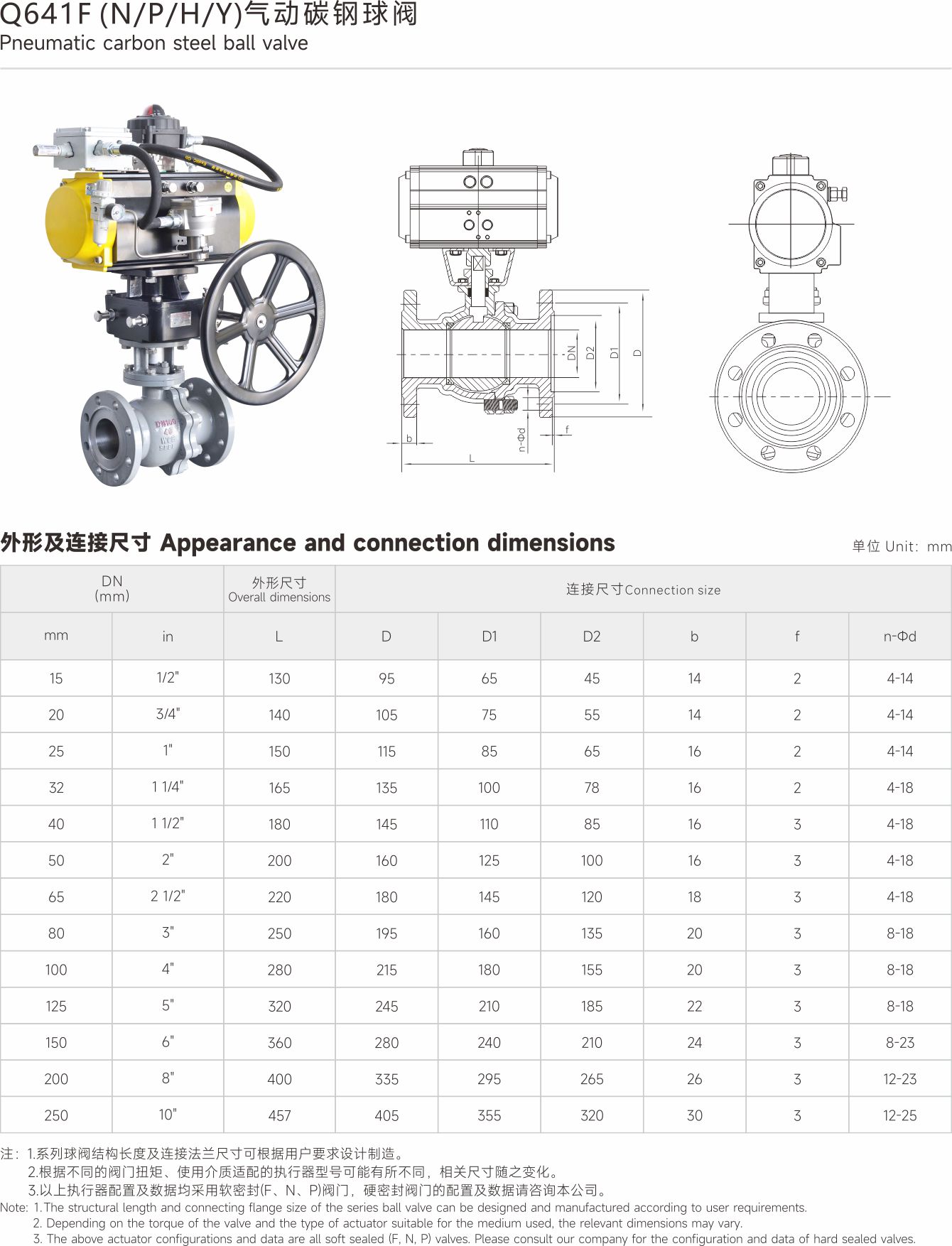

四.The main shape and connection size