I. Product Introduction

II. Product Features

- Stable Flange Connection

Adopts standard flange dimensions (compliant with HG/T20592 or customized by contract), ensuring tight sealing and strong load-bearing capacity. It effectively prevents medium leakage and adapts to various pipeline connection requirements.

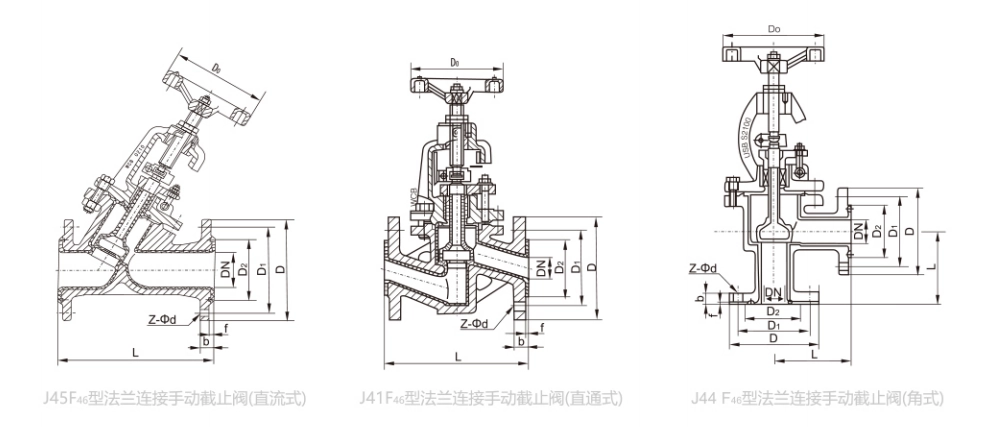

- Diversified Structure Forms

Straight-through, direct-flow, and angle type structures are available to suit different pipeline layouts:

- Straight-through and direct-flow types are suitable for horizontal pipeline systems, reducing flow resistance and improving throttling performance.

- Angle type is ideal for pipeline turning scenarios, saving installation space and reducing pipeline elbows.

- Excellent Corrosion Resistance

The fully lined structure uses high-performance corrosion-resistant materials (FEP/F46, PCTFE/F3, PFA, PO) for the lining and seat, isolating the medium from the valve body and internal components, and ensuring stable operation in corrosive working conditions.

- Multiple Operation Modes

Supports manual, pneumatic, and electric actuation to meet diverse control needs:

- Manual operation: Simple structure, low cost, suitable for local control scenarios with low frequency of operation.

- Pneumatic operation: Fast response speed, high control precision, applicable to automatic control systems with centralized regulation.

- Electric operation: Realizes remote control and intelligent regulation, easy to integrate with PLC, DCS and other control systems.

- Standardized Design and Manufacturing

Complies with national standards such as GB/T12233/GB/T12235 for design and manufacturing, ensuring product quality and interchangeability. Pressure test strictly follows GB/T13927 to guarantee safe and reliable operation under rated pressure.

III. Technical Data

1. Basic Parameters

| Item | Specification |

|---|---|

| Basic Structure Form | Straight-through, direct-flow, angle type |

| Nominal Pressure | PN0.6 ~ 1.6 MPa |

| Nominal Diameter | Straight-through/direct-flow type: DN15 ~ 350 mm; Angle type: DN15 ~ 300 mm |

2. Implementation Standards

| Standard Category | Standard Number |

|---|---|

| Design and Manufacturing | GB/T12233 / GB/T12235 |

| Structure Length | GB/T12221 / HG3704 |

| Flange Size | HG/T20592 (or by contract) |

| Pressure Test | GB/T 13927 |

| Symbolization | GB/T 12220 |

| Filling | GB/T 12252 |

3. Basic Model (Fully Lined)

| Operation Mode | Model |

|---|---|

| Manually Operated | J41F3, J41F46, J41F4; J45F3, J45F46, J45F4 |

| Aerodynamic | J6B41F3, J6B41F46, J6B41F4 |

| Electric Powered | J941F3, J941F46, J941F4 |

4. Main Parts and Components Material Table

| Serial Number | Part Name | Gray Cast Iron (Z) | Carbon Steel (C) | Stainless Steels (P) |

|---|---|---|---|---|

| 1 | Valve body, valve cover | HT250 | WCB | CF8 |

| 2 | Flap, stem | 35 | 1Cr13 | 1Cr18Ni19 |

| 3 | Lining/seat | FEP(F46), PCTFE(F3), PFA, PO | FEP(F46), PCTFE(F3), PFA, PO | FEP(F46), PCTFE(F3), PFA, PO |

| 4 | Packing material | PTFE(F4) | PTFE(F4) | PTFE(F4) |

| 5 | Packing Gland | WCB | WCB | CF8 |

| 6 | Handwheels | HT200 | HT200 | WCC |

Ⅳ.The main shape and connection size

Main connection size and weight(J41F46,J45F46)

| Nominal diameter

DN(mm) |

Standard value (unit: mm) | reference point | |||||||

| L | D | D₁ | D₂ | f | b | Z-Φd | Do | W(kg) | |

| PN1.6MPa | |||||||||

| 15 | 130 | 95 | 65 | 45 | 3 | 16 | 4-Φ14 | 100 | 4 |

| 20 | 150 | 105 | 75 | 58 | 3 | 18 | 4-Φ14 | 120 | 5 |

| 25 | 160 | 115 | 85 | 68 | 3.5 | 18 | 4-Φ14 | 120 | 6 |

| 32 | 180 | 140 | 100 | 78 | 3.5 | 18 | 4-Φ18 | 140 | 9 |

| 40 | 200 | 150 | 110 | 88 | 3.5 | 18 | 4-Φ18 | 160 | 11 |

| 50 | 230 | 165 | 125 | 102 | 4 | 18 | 4-Φ18 | 180 | 14 |

| 65 | 290 | 185 | 145 | 122 | 4 | 18 | 8-Φ18 | 220 | 21 |

| 80 | 310 | 200 | 160 | 138 | 4 | 20 | 8-Φ18 | 250 | 30 |

| 100 | 350 | 220 | 180 | 158 | 4.5 | 20 | 8-Φ18 | 280 | 36 |

| 125 | 400 | 250 | 210 | 188 | 4.5 | 22 | 8-Φ18 | 300 | 70 |

| 150 | 480 | 285 | 240 | 212 | 4.5 | 22 | 8-Φ22 | 350 | 80 |

| 200 | 600 | 340 | 295 | 268 | 5 | 24 | 12-Φ22 | 400 | |

| 250 | 650 | 405 | 355 | 320 | 5 | 26 | 12-Φ26 | 450 | 250 |

| 300 | 698 | 460 | 410 | 378 | 5 | 28 | 12-Φ26 | 500 | |

| 350 | 787 | 520 | 470 | 428 | 5 | 30 | 16-Φ26 | 600 | 500 |

| PN2.5MPa | |||||||||

| 15 | 130 | 95 | 65 | 45 | 3 | 16 | 4-Φ14 | 265 | 4 |

| 20 | 150 | 105 | 75 | 58 | 3 | 18 | 4-Φ14 | 270 | 5 |

| 25 | 160 | 115 | 85 | 68 | 3.5 | 18 | 4-Φ14 | 275 | 6 |

| 32 | 180 | 140 | 100 | 78 | 3.5 | 18 | 4-Φ18 | 290 | 9 |

| 40 | 200 | 150 | 110 | 88 | 3.5 | 18 | 4-Φ18 | 320 | 11 |

| 50 | 230 | 165 | 125 | 102 | 4 | 20 | 4-Φ18 | 335 | 14 |

| 65 | 290 | 185 | 145 | 122 | 4 | 22 | 8-Φ18 | 400 | 21 |

| 80 | 310 | 200 | 160 | 138 | 4 | 24 | 8-Φ18 | 450 | 30 |

| 100 | 350 | 235 | 190 | 162 | 4.5 | 24 | 8-Φ22 | 495 | 36 |

| 125 | 400 | 270 | 220 | 188 | 4.5 | 26 | 8-Φ26 | 560 | 70 |

| 150 | 480 | 300 | 250 | 218 | 4.5 | 28 | 8-Φ26 | 650 | 80 |

| 200 | 600 | 360 | 310 | 278 | 5 | 30 | 12-Φ26 | 750 | |

| 250 | 650 | 425 | 370 | 335 | 5 | 32 | 12-Φ30 | 840 | 250 |

| 300 | 698 | 485 | 430 | 395 | 5 | 34 | 16-Φ30 | 970 | |

| 350 | 787 | 555 | 490 | 450 | 5 | 38 | 16-Φ33 | 500 | |

Main connection size and weight(J44F46)

| Nominal diameter

DN(mm) |

Standard value (unit: mm) | reference point | |||||||

| L | D | D1 | D2 | f | b | Z-Φd | D0 | W(kg) | |

| PN1.0(MPa) | |||||||||

| 15 | 90 | 95 | 65 | 45 | 3 | 16 | 4-Φ14 | 120 | 7 |

| 20 | 95 | 105 | 75 | 58 | 3 | 18 | 4-Φ14 | 120 | 7.5 |

| 25 | 100 | 115 | 85 | 68 | 3.5 | 18 | 4-Φ14 | 120 | 8 |

| 32 | 105 | 140 | 100 | 78 | 3.5 | 18 | 4-Φ18 | 140 | 12 |

| 40 | 115 | 150 | 110 | 88 | 3.5 | 18 | 4-Φ18 | 160 | 14 |

| 50 | 125 | 165 | 125 | 102 | 4 | 18 | 4-Φ18 | 180 | 18 |

| 65 | 145 | 185 | 145 | 122 | 4 | 18 | 8-Φ18 | 220 | 27 |

| 80 | 155 | 200 | 160 | 138 | 4 | 20 | 8-Φ18 | 250 | 42 |

| 100 | 175 | 220 | 180 | 158 | 4.5 | 20 | 8-Φ18 | 280 | 50 |

| 125 | 200 | 250 | 210 | 188 | 4.5 | 22 | 8-Φ18 | 300 | 64 |

| 150 | 240 | 285 | 240 | 212 | 4.5 | 22 | 8-Φ22 | 350 | 85 |

| 200 | 275 | 340 | 295 | 268 | 5 | 24 | 8-Φ22 | 400 | 105 |

| 250 | 325 | 395 | 350 | 320 | 5 | 26 | 12-Φ22 | 450 | 135 |

| 300 | 375 | 445 | 400 | 370 | 5 | 26 | 12-Φ22 | 500 | 155 |

| PN1.6(MPa) | |||||||||

| 15 | 90 | 95 | 65 | 45 | 3 | 16 | 4-Φ14 | 120 | 7 |

| 20 | 95 | 105 | 75 | 58 | 3 | 18 | 4-Φ14 | 120 | 7.5 |

| 25 | 100 | 115 | 85 | 68 | 3.5 | 18 | 4-Φ14 | 120 | 8.5 |

| 32 | 105 | 140 | 100 | 78 | 3.5 | 18 | 4-Φ18 | 140 | 12 |

| 40 | 115 | 150 | 110 | 88 | 3.5 | 18 | 4-Φ18 | 160 | 14 |

| 50 | 125 | 165 | 125 | 102 | 4 | 18 | 4-Φ18 | 180 | 18 |

| 65 | 145 | 185 | 145 | 122 | 4 | 18 | 8-Φ18 | 220 | 27 |

| 80 | 155 | 200 | 160 | 138 | 4 | 20 | 8-Φ18 | 250 | 42 |

| 100 | 175 | 220 | 180 | 158 | 4.5 | 20 | 8-Φ18 | 280 | 50 |

| 125 | 200 | 250 | 210 | 188 | 4.5 | 22 | 8-Φ18 | 300 | 64 |

| 150 | 240 | 285 | 240 | 212 | 4.5 | 22 | 8-Φ22 | 350 | 85 |

| 200 | 275 | 340 | 295 | 268 | 5 | 24 | 12-Φ22 | 400 | 155 |