I. Product Introduction

The Fluorine Lined Control Valve is a high-performance control valve specifically designed for harsh working conditions involving strong corrosion, high viscosity, or easy-to-caking media. It integrates the advantages of reliable flow control and excellent corrosion resistance, with the inner cavity of the valve body and key flow-passing components lined with high-performance fluoroplastic materials. These materials possess superior chemical stability, ensuring that the valve can maintain stable operation in environments with strong acids, strong alkalis, oxidants, and various organic solvents without being corroded.

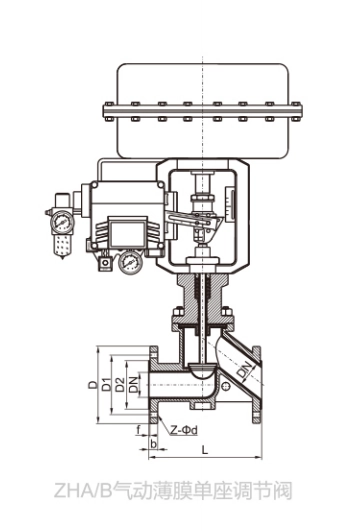

This type of valve is widely used in various industrial fields such as chemical industry, petrochemical industry, pharmaceutical industry, food and beverage industry, and environmental protection engineering. It is mainly used to regulate the flow, pressure, and temperature of corrosive media in pipelines, realizing accurate control of the production process and ensuring the safety, stability, and efficiency of the production system. Among them, the Pneumatic Membrane Single Seat Fully Lined Adjustment Valve is a mainstream model, which drives the spool movement through pneumatic power, with the characteristics of sensitive response, stable adjustment performance, and convenient maintenance.

II. Product Features

1. Excellent Corrosion Resistance: The valve body, seat, and other key flow-passing parts are lined with high-quality fluoroplastic materials such as FEP (F46), PTFE (F4), PFA (Soluble polytetrafluoroethylene), and PO (polyolefin). These materials have almost no reaction with most chemical media, can resist the corrosion of strong acids (such as sulfuric acid, nitric acid), strong alkalis (such as sodium hydroxide), oxidants, and organic solvents, and effectively extend the service life of the valve.

2. Stable and Reliable Adjustment Performance: The Pneumatic Membrane Single Seat structure is adopted, with a single-seated plunger spool. The spool has a reasonable flow channel design, which can realize accurate adjustment of the medium flow. The pneumatic membrane actuator has the advantages of sensitive response, small dead zone, and stable output force, ensuring that the valve can quickly and accurately respond to the control signal and maintain the stability of the regulated parameter.

3. Good Sealing Performance: The valve seat and spool adopt a precision matching structure, and the lining material itself has good elasticity and wear resistance, which can form an effective seal between the spool and the seat. At the same time, the packing uses PTFE (F4) material with excellent sealing performance, which can effectively prevent the leakage of corrosive media and ensure the safety of the production site and the environment.

4. Wide Adaptability to Media: It is suitable for various corrosive media such as strong acids, strong alkalis, salts, oxidants, and organic solvents, and can also be used for media with certain viscosity and slight solid particles (without damaging the lining). Different lining materials can be selected according to the characteristics of the medium to meet the needs of different working conditions.

5. Compliance with Multiple Standards: The design, manufacturing, structure length, flange size, pressure test, and symbolization of the product all comply with relevant national and international standards such as GB/T17213, GB/T 4213, GB/T 12221, and ASME 16.5, ensuring the interchangeability and universality of the product and facilitating installation, maintenance, and replacement.

6. Durable Main Components: The valve body, valve cover, and packing gland are made of high-quality carbon steel (WCB) or stainless steel (CF8, CF8M, CF3, CF3M) materials, which have good mechanical properties and rigidity. The spool and stem are made of stainless steel or ultra-low carbon stainless steel, which have good wear resistance and corrosion resistance, ensuring the overall reliability and durability of the valve.

III. Technical Data (Pneumatic Membrane Single Seat Adjustment Valve (Fully Lined))

1. Basic Parameters

-

Nominal Pressure: PN0.6~1.6MPa

-

Nominal Diameter: DN25~200(mm) / NPS 1″~8″

-

Spool Type: Single Seated Plunger Spool Valve

-

Basic Models: ZHA/B, ZAZA/B

2. Implementation Standards

-

Design and Manufacturing: GB/T17213, GB/T 4213

-

Structure Length: GB/T 12221

-

Flange Size: ASME 16.5, HG/T 20592

-

Pressure Test: GB/T4213

-

Symbolization: GB/T17213.5

3. Main Components & Material Selection

|

Serial Number

|

Part Name

|

Carbon Steel

|

Stainless Steels

|

Ultra-low Carbon Stainless Steel

|

|||

|---|---|---|---|---|---|---|---|

|

C

|

P

|

R

|

PL

|

RL

|

|||

|

1

|

Valve body, valve cover

|

WCB

|

CF8

|

CF8M

|

CF3

|

CF3M

|

|

|

2

|

Spool, stem

|

1Cr13

|

1Cr18Ni9

|

00Cr17Ni4Mo2

|

1Cr18Ni9

|

00Cr17Ni4Mo2

|

|

|

3

|

Lining/seat

|

FEP(F46), PTFE(F4), PFA(Soluble polytetrafluoroethylene), PO(polyolefin)

|

|||||

|

4

|

Packing material

|

PTFE(F4)

|

|||||

|

5

|

Packing Gland

|

WCB

|

CF8

|

CF8

|

CF8

|

CF8

|

|

Ⅳ.The main shape and connection size

| Nominal diameter | DN25 | DN32 | DN40 | DN50 | DN65 | DN80 | DN100 | DN125 | DN150 | DN200 |

| Cv(be) worth | 10 | 16 | 24 | 44 | 68 | 125 | 165 | 195 | 320 | 450 |

| Seat diameter | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 110 | 120 | 170 |

| Rated Stroke | 16 | 16 | 25 | 25 | 38 | 38 | 38 | 50 | 50 | 60 |

| Nominal pressure | 1.0MPa、1.6MPa | |||||||||

| operating temperature | -29°C-180℃ | |||||||||

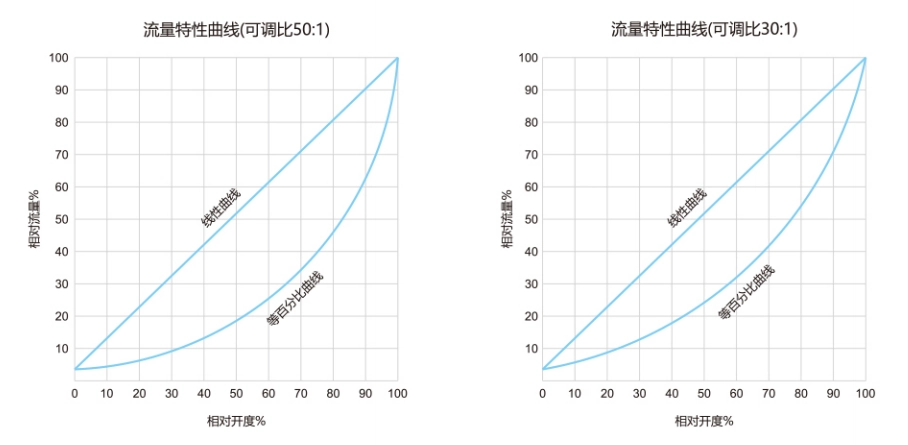

| flow curve | Straight line, equal percentage | |||||||||

| structural form | Single Seated Plunger Spool Valve | |||||||||

| model number | ZHA/B-22 | ZHA/B-23 | ZHA/B-34 | ZHA/B-45 | ||||||

| fundamental error | With positioner ±1%;Without positioner ±5% | |||||||||

| return differential (e.g. of farmland) | With positioner ±1%;Without positioner ±3% | |||||||||

| deadband | With positioner ± 0.5%; without positioner ± 5% | |||||||||

| Travel deviation | With positioner ±1%; without positioner ±2% for start point, ±2% for end point | |||||||||

| constant-point deviation | With positioner ± 0.5%; without positioner ± 1% | |||||||||

| spill | Not greater than CV x 10-6 | |||||||||