I. Product Introduction

The V-regulating Ceramic Ball Valve is a high-performance control valve integrating precise regulation, excellent sealing, and strong anti-abrasion properties. It boasts a series of core advantages, including precise control performance, small flow resistance, large flow coefficient, simple and compact structure, and reliable sealing performance. The valve is equipped with an equal percentage flow curve, which enables more accurate and flexible adjustment of medium flow, featuring a wide adjustable ratio range and fast adjustment speed to meet the diverse flow control needs of different industrial scenarios.

A prominent feature of this valve lies in its unique V-shaped channel design. During the opening and closing process, the V-shaped channel of the ball and the valve seat form a strong shearing effect on the medium. This shearing effect can effectively remove fibers, solid particles, and other impurities contained in the medium, avoiding channel blockage and ensuring the stable operation of the valve. Thanks to these outstanding performances, the V-regulating Ceramic Ball Valve is widely used in various industrial fields such as electric power, chemical industry, metallurgy, mining, and sewage treatment, and can adapt to harsh working conditions with medium containing impurities.

The design, manufacturing, and testing of the V-regulating Ceramic Ball Valve strictly comply with relevant national and international standards to ensure product quality and performance stability. The specific implementation standards are as follows:

Implementation Standards

-

Design and Manufacturing: GB/T 12237, API6D

-

Structure Length: GB/T 12221

-

Flange Size: HG/T 20592, ASME B16.5

-

Pressure Test: GB/T 13927

-

Symbolization: GB/T 12220

-

Filling: GB/T 12252

II. Product Features

-

Precise Regulation Performance: Adopts an equal percentage flow curve, which can achieve precise and flexible adjustment of medium flow. The adjustable ratio range is wide, and the adjustment speed is fast, ensuring that the flow can be stably controlled within the required range, suitable for occasions with high requirements for flow regulation accuracy.

-

Excellent Anti-clogging Performance: The unique V-shaped channel design forms a strong shearing effect between the ball and the valve seat during the opening and closing process. This effect can effectively cut off fibers, solid particles, and other impurities in the medium, preventing channel blockage and ensuring the smooth flow of the medium.

-

Superior Sealing Performance: The key sealing components such as the seat and ball adopt high-performance ceramic materials. Ceramic materials have excellent wear resistance, corrosion resistance, and high-temperature resistance, which can ensure the reliable sealing of the valve even in harsh working conditions, effectively preventing medium leakage.

-

Small Flow Resistance & Large Flow Coefficient: The optimized internal flow channel design reduces the flow resistance of the medium, improves the flow capacity of the valve, and has a large flow coefficient. It can meet the needs of large flow medium transportation and reduce energy consumption.

-

Simple Structure & Easy Maintenance: The overall structure of the valve is simple and compact, with fewer wearing parts. The installation, disassembly, and maintenance processes are convenient, which can reduce the maintenance cost and workload of the user and improve the operation efficiency.

-

Wide Adaptability: Strictly complies with relevant national and international standards in design and manufacturing. It has a wide range of nominal pressure and nominal diameter options, and can be adapted to different medium types and working conditions. It is widely used in multiple industrial fields.

III. Technical Data

Basic Parameters

-

Nominal Pressure: PN0.6-1.6 (MPa)

-

Nominal Diameter: DN25~200 (mm); NPS 1°~10°

-

Basic Models: Q641TC, Q941TC

Main Components & Material Selection

|

Serial Number

|

Part Name

|

Carbon Steel (C)

|

Stainless Steels (P/R)

|

Ultra-low Carbon Stainless Steel (PL/RL)

|

|---|---|---|---|---|

|

1

|

Valve Body, Valve Cover

|

A105N

|

304 (P), 316 (R)

|

304L (PL), 316L (RL)

|

|

2

|

Tappet

|

20Cr13

|

304 (P), 17-4PH (R)

|

316L (PL), 17-4PH (RL)

|

|

3

|

Seat, Ball, Center Sleeve

|

Al₂O₃ (Aluminum Oxide), ZrO₂ (Zirconium Oxide)

|

||

|

4

|

Packing Material

|

Graphite, PTFE

|

||

|

5

|

Packing Gland

|

WCB

|

CF8 (P/R)

|

CF8 (PL/RL)

|

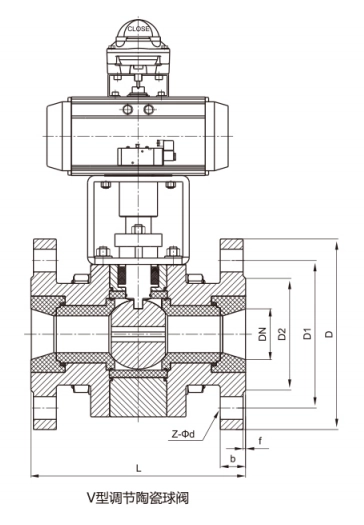

Ⅳ.The main shape and connection size

| Nominal diameter | Standard value (unit: mm) | ||||||

| DN(mm) | L | D | D1 | D2 | b | f | Z-Φd |

| PN1.0(MPa) | |||||||

| 15 | 130 | 95 | 65 | 45 | 16 | 2 | 4-Φ14 |

| 20 | 130 | 105 | 78 | 58 | 18 | 2 | 4-Φ14 |

| 25 | 140 | 115 | 85 | 68 | 18 | 2 | 4-Φ14 |

| 32 | 165 | 140 | 100 | 78 | 18 | 2 | 4-Φ18 |

| 40 | 165 | 150 | 110 | 88 | 18 | 3 | 4-Φ18 |

| 50 | 203 | 165 | 125 | 102 | 18 | 3 | 4-Φ18 |

| 65 | 222 | 185 | 145 | 122 | 18 | 3 | 8-Φ18 |

| 80 | 241 | 200 | 160 | 138 | 20 | 3 | 8-Φ18 |

| 100 | 305 | 220 | 180 | 158 | 20 | 3 | 8-Φ18 |

| 125 | 356 | 250 | 210 | 188 | 22 | 3 | 8-Φ18 |

| 150 | 394 | 285 | 240 | 212 | 22 | 3 | 8-Φ22 |

| 200 | 457 | 340 | 295 | 268 | 24 | 3 | 8-Φ22 |

| 250 | 533 | 395 | 350 | 320 | 26 | 3 | 12-Φ22 |

| 300 | 610 | 445 | 400 | 370 | 26 | 4 | 12-Φ22 |

| Nominal diameter | Standard value (unit: mm) | ||||||

| DN(mm) | L | D | D1 | D2 | b | f | Z-Φd |

| PN1.6(MPa) | |||||||

| 15 | 130 | 95 | 65 | 45 | 16 | 2 | 4-Φ14 |

| 20 | 130 | 105 | 78 | 58 | 18 | 2 | 4-Φ14 |

| 25 | 140 | 115 | 85 | 68 | 18 | 2 | 4-Φ14 |

| 32 | 165 | 140 | 100 | 78 | 18 | 2 | 4-Φ18 |

| 40 | 165 | 150 | 110 | 88 | 18 | 3 | 4-Φ18 |

| 50 | 203 | 165 | 125 | 102 | 18 | 3 | 4-Φ18 |

| 65 | 222 | 185 | 145 | 122 | 18 | 3 | 8-Φ18 |

| 80 | 241 | 200 | 160 | 138 | 20 | 3 | 8-018 |

| 100 | 305 | 220 | 180 | 158 | 20 | 3 | 8-Φ18 |

| 125 | 356 | 250 | 210 | 188 | 22 | 3 | 8-Φ18 |

| 150 | 394 | 285 | 240 | 212 | 22 | 3 | 8-Φ22 |

| 200 | 457 | 340 | 295 | 268 | 24 | 3 | 12-Φ22 |

| 250 | 533 | 405 | 355 | 320 | 26 | 3 | 12-Φ26 |

| 300 | 610 | 460 | 410 | 378 | 28 | 4 | 12-Φ26 |