I. Product Introduction

The PTFE PFA Lining Flange Connection Check Valve is a specialized check valve designed for harsh medium environments, featuring flange connection and high-performance fluoroplastic lining. It is mainly used to prevent the backflow of medium in pipelines, relying on the pressure of the medium itself to automatically open and close the flap, without the need for additional manual or power control, ensuring the safe and stable operation of the pipeline system.

The core advantage of this valve lies in its high-quality lining materials such as PTFE, PFA, and FEP. These fluoroplastic materials have excellent chemical corrosion resistance, can resist the erosion of most strong acids, strong alkalis, oxidants, and organic solvents, and also have good high-temperature resistance and non-stick properties. Combined with the flange connection method, it has the characteristics of reliable connection, good sealing performance, and convenient installation and maintenance, making it widely applicable to chemical, petrochemical, pharmaceutical, food and beverage, water treatment and other industries, especially suitable for pipeline systems transporting corrosive media.

The entire research and development, design, and manufacturing process of the valve strictly abides by relevant national and industrial standards, ensuring that the product’s performance, dimensions, and quality meet the requirements of industrial application scenarios. The specific implementation standards are detailed as follows:

Implementation Standards

-

Design and Manufacturing: GB/T 12235

-

Structure Length: GB/T 12221, HG/T 3704

-

Flange Size: HG/T 20592 (or as required by the contract)

-

Pressure Test: GB/T 13927

-

Symbolization: GB/T 12220

-

Filling: GB/T 12252

II. Product Features

-

Excellent Corrosion Resistance: The inner lining and seat adopt high-performance fluoroplastic materials such as PTFE, PFA, FEP, and PCTFE. These materials have almost universal corrosion resistance, can withstand the erosion of various strong corrosive media such as strong acids, strong alkalis, and organic solvents, and are not easy to react with the medium, ensuring the long-term stable operation of the valve.

-

Reliable Check Function: The valve flap is designed with a reasonable structure, which can quickly respond to changes in medium pressure. When the medium flows forward, the flap opens smoothly under the action of medium pressure; when the medium tends to flow backward, the flap closes tightly in time relying on its own weight and medium back pressure, effectively preventing medium backflow and avoiding potential safety hazards in the pipeline.

-

Stable Sealing Performance: The combination of flange connection and fluoroplastic lining ensures double sealing reliability. The flange connection is tight and not easy to leak, and the fluoroplastic lining has good elasticity and non-stick properties, which can fit closely with the flap, further improving the sealing effect and avoiding medium leakage.

-

Wide Adaptability: It covers a wide range of nominal pressure (PN0.6~1.6MPa) and nominal diameter (DN15~500mm), and provides multiple basic models for selection. At the same time, the flange size can be customized according to the contract requirements, which can meet the needs of different pipeline specifications and working conditions in various industries.

-

Durable & Easy Maintenance: The valve body and bonnet are made of high-quality materials such as gray cast iron, carbon steel, and stainless steel, which have high mechanical strength and wear resistance. The structure is simple, the number of wearing parts is small, and the disassembly and maintenance are convenient, which reduces the later maintenance cost and extends the service life of the valve.

-

Good Flow Performance: The inner cavity of the valve is smooth, and the fluoroplastic lining has a low friction coefficient, which can reduce the flow resistance of the medium, reduce energy consumption, and ensure the smooth flow of the medium in the pipeline.

III. Technical Data

Basic Parameters

-

Nominal Pressure: PN0.6~1.6 (MPa)

-

Nominal Diameter: DN15~500 (mm)

-

Basic Models: H41PFA, H41F46, H41F4

Main Components & Material Selection

|

Serial Number

|

Part Name

|

Gray Cast Iron (Z)

|

Carbon Steel (C)

|

Stainless Steels (P/R)

|

Ultra-low Carbon Stainless Steel (PL/RL)

|

|---|---|---|---|---|---|

|

1

|

Valve Body, Valve Cover

|

HT250

|

WCB

|

CF8 (P), CF8M (R)

|

CF3 (PL), CF3M (RL)

|

|

2

|

Lining/Seat

|

FEP (F46), PCTFE (F3), PFA (Soluble Polytetrafluoroethylene), PO (Polyolefin)

|

|||

|

3

|

Shaft, Flap (Plate)

|

–

|

1Cr13/35, WCB

|

1Cr18Ni9/CF8

|

00Cr17Ni14Mo2/CF3M

|

|

4

|

Bolt (Male Component of Nut and Bolt)

|

35

|

35

|

1Cr17Ni2

|

1Cr18Ni9T

|

|

5

|

Nut (Female Component of Nut and Bolt)

|

45

|

45

|

0Cr18Ni9

|

0Cr18Ni9

|

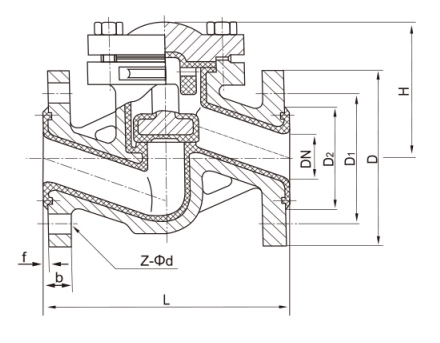

Ⅳ.The main shape and connection size

Main connection dimensions and weight

| Nominal diameter

DN(mm) |

Standard value (unit: mm) | reference point | |||||||

| L | D | D1 | D2 | f | b | Z-Φd | H | W(kg) | |

| Long Short | PN0.6(MPa) | ||||||||

| 15 | 130 | 80 | 55 | 40 | 3 | 12 | 4-Φ11 | 55 | 4 |

| 20 | 150 | 90 | 65 | 50 | 3 | 14 | 4-Φ11 | 58 | 5 |

| 25 | 160 | 100 | 75 | 60 | 3.5 | 14 | 4-Φ11 | 60 | 6 |

| 32 | 180 | 120 | 90 | 70 | 3.5 | 14 | 4-Φ14 | 75 | 7 |

| 40 | 200 | 130 | 100 | 80 | 3.5 | 14 | 4-Φ14 | 82 | 8 |

| 50 | 230 | 140 | 110 | 90 | 4 | 14 | 4-Φ14 | 95 | 10 |

| 65 | 290 | 160 | 130 | 110 | 4 | 14 | 4-Φ14 | 105 | 20 |

| 80 | 310 | 190 | 150 | 128 | 4 | 16 | 4-Φ18 | 120 | 25 |

| 100 | 350 | 210 | 170 | 148 | 4.5 | 16 | 4-Φ18 | 135 | 30 |

| 125 | 400 | 240 | 200 | 178 | 4.5 | 18 | 8-Φ18 | 158 | 50 |

| 150 | 480 | 265 | 225 | 202 | 4.5 | 18 | 8-Φ18 | 180 | 65 |

| 200 | 600 | 320 | 280 | 258 | 5 | 20 | 8-Φ18 | 215 | 137 |

| 250 | 650 | 375 | 335 | 312 | 5 | 22 | 12-Φ18 | 240 | 150 |

| 300 | 698 | 440 | 395 | 365 | 5 | 22 | 12-Φ22 | 265 | 185 |

| 350 | 787 | 490 | 445 | 415 | 5 | 22 | 12-Φ22 | 300 | 215 |

| 400 | 914 | 540 | 495 | 465 | 5 | 22 | 16-Φ22 | 360 | 244 |

| 450 | 978 | 595 | 550 | 520 | 6 | 22 | 16-Φ22 | 385 | 276 |

| 500 | 978 | 645 | 600 | 570 | 6 | 24 | 20-Φ22 | 415 | 315 |

Main connection dimensions and weight

| Nominal diameter

DN(mm) |

Standard value (unit: mm) | reference point | |||||||

| L | D | D1 | D2 | f | b | Z-Φd | H | W(kg) | |

| Long Short | PN1.0(MPa) | ||||||||

| 15 | 130 | 65 | 45 | 3 | 16 | 4-Φ14 | 55 | 5 | |

| 20 | 150 | 105 | 75 | 58 | 3 | 18 | 4-Φ14 | 58 | 7 |

| 25 | 160 | 115 | 85 | 68 | 3.5 | 18 | 4-Φ14 | 60 | 9 |

| 32 | 180 | 140 | 100 | 78 | 3.5 | 18 | 4-Φ18 | 75 | 11 |

| 40 | 200 | 150 | 110 | 88 | 3.5 | 18 | 4-Φ18 | 82 | 13.5 |

| 50 | 230 | 165 | 125 | 102 | 4 | 18 | 4-Φ18 | 95 | 18 |

| 65 | 290 | 185 | 145 | 122 | 4 | 18 | 8-Φ18 | 105 | 22 |

| 80 | 310 | 200 | 160 | 138 | 4 | 20 | 8-Φ18 | 120 | 28 |

| 100 | 350 | 220 | 180 | 158 | 4.5 | 20 | 8-Φ18 | 135 | 34 |

| 125 | 400 | 250 | 210 | 188 | 4.5 | 22 | 8-Φ18 | 158 | 58 |

| 150 | 480 | 285 | 240 | 212 | 4.5 | 22 | 8-Φ22 | 180 | 72 |

| 200 | 600 | 340 | 295 | 268 | 5 | 24 | 8-Φ22 | 215 | 150 |

| 250 | 650 | 395 | 350 | 320 | 5 | 26 | 12-Φ22 | 240 | 165 |

| 300 | 698 | 445 | 400 | 370 | 5 | 26 | 12-Φ22 | 265 | 190 |

| 350 | 787 | 505 | 460 | 430 | 5 | 26 | 16-Φ22 | 300 | 225 |

| 400 | 914 | 565 | 515 | 482 | 5 | 26 | 16-Φ26 | 360 | 254 |

| 450 | 978 | 615 | 565 | 532 | 6 | 28 | 20-Φ26 | 385 | 285 |

| 500 | 978 | 670 | 620 | 585 | 6 | 28 | 20-Φ26 | 415 | 333 |

Main connection dimensions and weight

| Nominal diameter

DN(mm) |

Standard value (unit: mm) | reference point | |||||||

| L | D | D1 | D2 | f | b | Z-Φd | H | W(kg | |

| Long Short | PN1.6(MPa) | ||||||||

| 15 | 130 | 95 | 65 | 45 | 3 | 16 | 4-Φ14 | 55 | 6 |

| 20 | 150 | 105 | 75 | 58 | 3 | 18 | 4-Φ14 | 58 | 7.8 |

| 25 | 160 | 115 | 85 | 68 | 3.5 | 18 | 4-Φ14 | 60 | 10 |

| 32 | 180 | 140 | 100 | 78 | 3.5 | 18 | 4-Φ18 | 75 | 12.5 |

| 40 | 200 | 150 | 110 | 88 | 3.5 | 18 | 4-Φ18 | 82 | 14.5 |

| 50 | 230 | 165 | 125 | 102 | 4 | 18 | 4-Φ18 | 95 | 19.5 |

| 65 | 290 | 185 | 145 | 122 | 4 | 18 | 8-Φ18 | 105 | 25.5 |

| 80 | 310 | 200 | 160 | 138 | 4 | 20 | 8-Φ18 | 120 | 30 |

| 100 | 350 | 220 | 180 | 158 | 4.5 | 20 | 8-Φ18 | 135 | 36 |

| 125 | 400 | 250 | 210 | 188 | 4.5 | 22 | 8-Φ18 | 158 | 62 |

| 150 | 480 | 285 | 240 | 212 | 4.5 | 22 | 8-Φ22 | 180 | 78 |

| 200 | 600 | 340 | 295 | 268 | 5 | 24 | 12-Φ22 | 215 | 156 |

| 250 | 650 | 405 | 355 | 320 | 5 | 26 | 12-Φ26 | 240 | 172 |

| 300 | 698 | 460 | 410 | 378 | 5 | 28 | 12-Φ26 | 265 | 240 |

| 350 | 787 | 520 | 470 | 428 | 5 | 30 | 16-Φ26 | 300 | 208 |

| 400 | 914 | 580 | 525 | 490 | 5 | 32 | 16-Φ30 | 350 | 265 |