I. Product Introduction

A flange extended stem fluoropolymer-lined butterfly valve is a specialized control valve that takes the rotating disc (connected to the extended stem) as its core opening and closing element, realizing the functions of opening, closing, and regulating the medium in pipelines. As a key member of the butterfly valve family, it is widely favored in various industrial fields due to its outstanding sealing performance, which is a core evaluation indicator. Compared with traditional valves such as gate valves with the same parameters, this valve has obvious advantages: it has a more compact structure, smaller volume, and lighter weight, with an average weight reduction of 30-50%. The opening and closing operation is simple and labor-saving—only a 90° rotation of the disc is required to complete the switching process. During operation, the medium exerts approximately equal forces on both sides of the disc, and the generated torques are opposite, so the opening and closing torque is relatively small, effectively reducing the operating load.

This series of valves mainly includes two basic types and their extended models to meet different working conditions: one is the flanged and wafer (centerline) fully lined butterfly valve, which adopts a two-piece valve body assembly structure, integrating the valve seat and the valve body lining; the other is the flanged and wafer-type semi-lined butterfly valve, an extended model of the fully lined type, with internal components such as the butterfly plate and stem (unlined) made of corrosion-resistant stainless steel, while the valve body is fully lined. Regardless of the type, the core design concept is to enhance corrosion resistance and sealing performance, ensuring stable operation in harsh medium environments.

II. Product Features

1. Excellent Corrosion Resistance

For fully lined butterfly valves, during operation, only the all-plastic valve seat and the plastic-lined butterfly plate are in contact with the medium, which can resist corrosion from any medium except molten alkali metals and elemental fluorine. The integrated forging structure of the valve stem and butterfly plate is coated with a uniform FEP layer on the surface, further enhancing the corrosion resistance of key components. For semi-lined butterfly valves, the unlined internal components (butterfly plate, stem, etc.) are made of corrosion-resistant stainless steel, and the valve body is fully lined, which not only ensures corrosion resistance but also improves the structural strength of the components.

2. Superior Sealing Performance with Zero Leakage

The product adopts a four-stage sealing structure, and the sealing surface is equipped with a temperature-resistant and aging-resistant SI rubber elastic pad valve seat, which can absolutely guarantee zero leakage of the medium inside and outside the valve. The specific performance of the four-stage loading elastic seal is reflected in four aspects: First, the special transition curve at the circumferential connection between the shaft head and the butterfly plate and the reasonable interference fit of the valve seat lay a foundation for reliable sealing; second, the shaft end face uses a combination of elastic O-ring, rigid washer, and elastic rubber pad at the shaft shoulder to block the medium from leaking along the shaft end face; third, the radial direction of the shaft adopts a combination of O-rings and metal washers to prevent radial leakage; fourth, the valve seat is installed in the flexible valve body groove, which can compensate for slight deviations and ensure tight fitting.

3. Excellent Flow Control Performance

The inner surface of the valve body passage is smooth, which effectively reduces fluid resistance, makes the CV value higher, and ensures strong flow capacity. At the same time, the torque during operation is moderate, which is convenient for precise adjustment of the valve. The centerline design of the valve (the entire butterfly plate and butterfly seat are concentric within the 360° circumference) enables bidirectional sealing, allowing free adjustment of pressure and flow rate according to actual working conditions, and has good adaptability to different pipeline operation requirements.

4. Stable and Reliable Structural Design

The integrated forging structure of the valve stem and butterfly plate enhances the connection strength between components, avoiding looseness or failure during long-term operation. The adjustable elastic ball positioning structure is adopted, which not only ensures the accuracy of the positioning of the valve stem and butterfly plate but also has the advantages of simple structure and convenient maintenance, reducing the difficulty and cost of later use.

5. Diverse Adaptability

It has two basic structural types: flanged and wafer type, which can be matched with different pipeline connection methods. The fully lined and semi-lined models can be selected according to the type of medium and corrosion intensity, covering a variety of industrial application scenarios and meeting the personalized needs of users.

III. Technical Data

-

Pressure Rating: Class 150

-

Materials: Valve body materials include gray cast iron, carbon steel, and stainless steel; the fully lined model’s valve seat and valve body lining are integrated with plastic materials, the valve stem and butterfly plate (forged) are surface-coated with FEP; the semi-lined model’s butterfly plate, stem, and other internal components are made of corrosion-resistant stainless steel, and the valve body is fully lined; the sealing surface is equipped with SI rubber elastic pad valve seat.

-

Standards: Complies with GB/T 12238 and API 609 standards

-

Connection Method: Flange connection

-

Size Range: NPS 1-1/2″ ~ 72″

-

Other Key Parameters: The valve body passage has a smooth inner surface, low fluid resistance, high CV value, strong flow capacity, and moderate opening and closing torque; it adopts a four-stage sealing structure to achieve zero leakage; the centerline design realizes bidirectional sealing and adjustable pressure and flow.

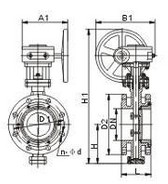

Ⅳ.The main shape and connection size

| Nominal Density (DN) | Main dimensions | Flange dimensions and bolt specifications | ||||||||||

| 1.0MPa | 1.6MPa | 2.5MPa | ||||||||||

| L | H1 | H | D | D1 | n-Фd | D | D1 | n-Фd | D | D1 | n-Фd | |

| 50 | 108 | 350 | 112 | 165 | 125 | 4-18 | 165 | 125 | 4-18 | 165 | 125 | 4-18 |

| 65 | 112 | 370 | 115 | 185 | 145 | 4-18 | 185 | 145 | 4-18 | 185 | 145 | 8-18 |

| 80 | 114 | 380 | 120 | 200 | 160 | 4-18 | 200 | 160 | 8-18 | 200 | 160 | 8-18 |

| 100 | 127 | 420 | 138 | 220 | 180 | 8-18 | 220 | 180 | 8-18 | 235 | 190 | 8-22 |

| 125 | 140 | 460 | 164 | 250 | 210 | 8-18 | 250 | 210 | 8-22 | 270 | 220 | 8-26 |

| 150 | 140 | 555 | 175 | 285 | 240 | 8-22 | 285 | 240 | 8-22 | 300 | 250 | 8-26 |

| 200 | 152 | 760 | 200 | 340 | 295 | 8-22 | 340 | 295 | 12-22 | 360 | 310 | 12-26 |

| 250 | 165 | 830 | 243 | 395 | 350 | 12-22 | 405 | 355 | 12-26 | 425 | 370 | 12-30 |

| 300 | 178 | 895 | 250 | 445 | 400 | 12-22 | 460 | 410 | 12-26 | 485 | 430 | 16-30 |

| 350 | 190 | 950 | 280 | 505 | 460 | 16-22 | 520 | 470 | 16-26 | 555 | 490 | 16-33 |

| 400 | 216 | 1190 | 305 | 565 | 515 | 16-26 | 580 | 525 | 16-30 | 620 | 550 | 16-36 |

| 450 | 222 | 1255 | 350 | 615 | 565 | 20-26 | 640 | 585 | 20-30 | 670 | 600 | 20-36 |

| 500 | 229 | 1305 | 380 | 670 | 620 | 20-26 | 715 | 650 | 20-33 | 730 | 660 | 20-36 |

| 600 | 267 | 1340 | 445 | 780 | 725 | 20-30 | 840 | 770 | 20-36 | 845 | 770 | 20-39 |

| 700 | 292 | 1520 | 480 | 895 | 840 | 24-30 | 910 | 840 | 24-36 | 960 | 875 | 24-42 |

| 800 | 318 | 1710 | 530 | 1015 | 950 | 24-33 | 1025 | 950 | 24-39 | 1085 | 990 | 24-48 |

| 900 | 330 | 1810 | 580 | 1115 | 1050 | 28-33 | 1125 | 1050 | 28-39 | 1185 | 1090 | 28-48 |

| 1000 | 410 | 1960 | 650 | 1230 | 1160 | 28-36 | 1255 | 1170 | 28-42 | 1320 | 1210 | 28-56 |

| 1200 | 470 | 2250 | 760 | 1455 | 1380 | 32-39 | 1485 | 1390 | 32-48 | 1530 | 1420 | 32-56 |

| 1400 | 530 | 2435 | 850 | 1675 | 1590 | 36-42 | 1685 | 1590 | 36-48 | 1755 | 1640 | 36-62 |

| 1600 | 600 | 2780 | 1030 | 1915 | 1820 | 40-48 | 1930 | 1820 | 40-56 | 1975 | 1860 | 40-62 |

| 1800 | 670 | 3020 | 1230 | 2115 | 2020 | 44-48 | 2130 | 2020 | 44-56 | 2195 | 2070 | 44-70 |

| 2000 | 760 | 3270 | 1350 | 2325 | 2230 | 48-48 | 2345 | 2230 | 48-62 | 2425 | 2300 | 48-70 |