I. Product Introduction

The BZ41H Insulation Valve is a specialized industrial valve designed for applications requiring effective thermal insulation to maintain medium temperature and prevent heat loss or gain. It is mainly used in pipelines transporting high-temperature, low-temperature, or easily crystallized media in industries such as petroleum, chemical, power generation, metallurgy, and food processing.

This valve adopts a reliable insulation structure, integrating the valve body with an insulation layer to ensure that the temperature of the medium inside the valve remains stable during transportation, thereby avoiding operational problems caused by temperature changes (such as medium crystallization, viscosity increase, or pipeline frost cracking). The BZ41H model features a flange connection design, which facilitates installation and maintenance, and is equipped with a sturdy valve core and seat to ensure excellent sealing performance and long service life. Whether in harsh high-temperature working environments or low-temperature freezing conditions, the BZ41H Insulation Valve can operate stably, providing a safe and efficient solution for industrial pipeline systems.

II. Product Features

-

Excellent Thermal Insulation Performance: The valve is equipped with a high-quality insulation layer made of advanced thermal insulation materials with low thermal conductivity. The insulation layer closely fits the valve body, forming a complete thermal insulation system that effectively reduces heat transfer between the medium inside the valve and the external environment. It can minimize heat loss for high-temperature media and prevent heat absorption for low-temperature media, ensuring the stability of medium properties.

-

Reliable Sealing Performance: Adopting a hard-sealed structure, the valve core and seat are made of wear-resistant and high-temperature-resistant alloy materials. After precision machining and grinding, they achieve a tight fit, effectively preventing medium leakage. Even in long-term high-pressure and high-temperature operating conditions, the sealing performance remains stable, avoiding safety hazards and economic losses caused by leakage.

-

Sturdy and Durable Structure: The valve body is made of high-quality carbon steel or stainless steel, which has excellent mechanical properties, corrosion resistance, and high-temperature resistance. The overall structure is reasonably designed, with strong pressure-bearing capacity and impact resistance, capable of adapting to harsh industrial working environments. The internal components are wear-resistant and fatigue-resistant, significantly extending the service life of the valve.

-

Easy Installation and Maintenance: The valve adopts a standard flange connection mode, which is consistent with universal industrial pipeline standards and can be quickly installed and connected without special tools. The valve cover is designed to be easy to disassemble, facilitating the inspection, maintenance, and replacement of internal components (such as valve core, seat, and stem) during later use, reducing maintenance costs and downtime.

-

Wide Application Range: It can be applied to various media, including water, steam, oil, gas, and various chemical media. It is suitable for both high-temperature (up to 425℃) and low-temperature (down to -40℃) working conditions, meeting the needs of different industrial fields such as petroleum refining, chemical engineering, thermal power generation, and food and beverage processing.

-

Smooth Flow Channel: The internal flow channel of the valve is designed to be smooth and streamlined, reducing flow resistance and pressure loss. It ensures the unobstructed transportation of the medium, improving the overall efficiency of the pipeline system and reducing energy consumption.

III. Technical Data

|

Item

|

Specification

|

|---|---|

|

Valve Model

|

BZ41H

|

|

Valve Type

|

Insulated Globe Valve

|

|

Nominal Diameter (DN)

|

DN15 – DN300

|

|

Nominal Pressure (PN)

|

PN10, PN16, PN25, PN40; Class150, Class300

|

|

Body Material

|

Carbon Steel (WCB), Stainless Steel (CF8, CF8M), Alloy Steel (WC6, WC9)

|

|

Trim Material (Core/Seat)

|

13Cr, STL (Stellite Alloy), F304, F316

|

|

Insulation Material

|

Rock Wool, Glass Wool, Polyurethane Foam, Ceramic Fiber (Customizable according to working conditions)

|

|

Working Temperature Range

|

-40℃ – 425℃ (Depends on body and insulation materials)

|

|

Working Medium

|

Water, Steam, Oil, Gas, Chemical Solutions, etc.

|

|

Connection Type

|

Flange (GB, HG, ANSI, DIN, JIS standards)

|

|

Operation Mode

|

Manual (Handwheel), Electric, Pneumatic (Customizable)

|

|

Sealing Performance

|

Class VI (Bubble-tight) according to API 598

|

|

Insulation Efficiency

|

≥90% (Under standard working conditions)

|

|

Test Standard

|

API 598, GB/T 13927

|

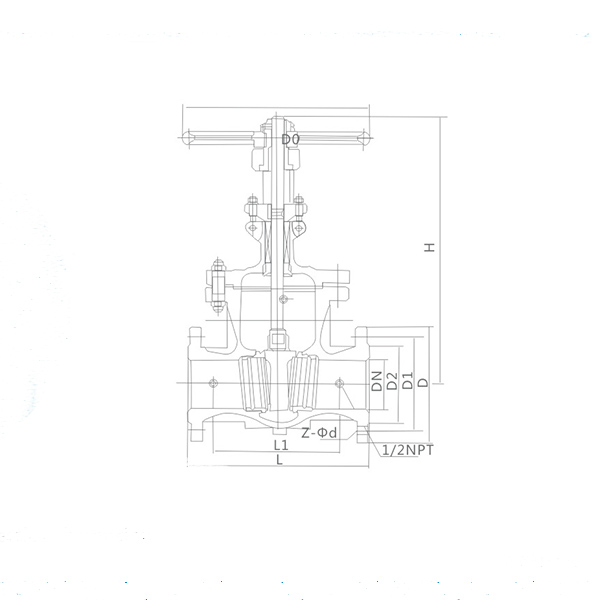

Ⅳ.The main shape and connection size

BZ41H-16C BZ41W-16P BZ41W-16R

| DN | Main external and connecting dimensions | WT

(Kg) |

||||||||

| L | L1 | D | D1 | D2 | b | Z- Φd | H | D0 | ||

| 40 | 200 | 70 | 160 | 125 | 100 | 18 | 4- Φ18 | 310 | 200 | 49 |

| 50 | 250 | 80 | 180 | 145 | 120 | 18 | 4- Φ18 | 358 | 240 | 54 |

| 65 | 270 | 90 | 195 | 160 | 135 | 20 | 8- Φ18 | 373 | 240 | 81 |

| 80 | 280 | 100 | 215 | 180 | 155 | 20 | 8- Φ18 | 435 | 280 | 100 |

| 100 | 300 | 100 | 245 | 210 | 185 | 22 | 8- Φ18 | 500 | 300 | 120 |

| 125 | 325 | 110 | 280 | 240 | 210 | 24 | 8- Φ23 | 614 | 320 | 210 |

| 150 | 350 | 120 | 335 | 295 | 265 | 26 | 12- Φ23 | 674 | 360 | 260 |

| 200 | 400 | 130 | 405 | 355 | 320 | 30 | 12- Φ25 | 818 | 400 | 300 |

| 250 | 450 | 140 | 460 | 410 | 375 | 30 | 12- Φ25 | 969 | 450 | 400 |

| 300 | 500 | 160 | 520 | 470 | 435 | 34 | 16- Φ25 | 1145 | 560 | 490 |

BZ41H-25 BZ41W-25P BZ41W-25R

| DN | Main external and connecting dimensions | WT

(Kg) |

||||||||

| L | L1 | D | D1 | D2 | b | Z- Φd | H | D0 | ||

| 40 | 200 | 70 | 160 | 125 | 100 | 20 | 4- Φ18 | 358 | 240 | 52 |

| 50 | 250 | 80 | 180 | 145 | 120 | 22 | 8- Φ18 | 373 | 240 | 56 |

| 65 | 270 | 90 | 195 | 160 | 135 | 22 | 8- Φ18 | 435 | 280 | 86 |

| 80 | 280 | 100 | 230 | 190 | 160 | 24 | 8- Φ18 | 500 | 300 | 105 |

| 100 | 300 | 100 | 270 | 220 | 188 | 28 | 8- Φ15 | 614 | 320 | 170 |

| 125 | 325 | 110 | 300 | 250 | 218 | 30 | 8- Φ25 | 674 | 360 | 245 |

| 150 | 350 | 120 | 360 | 310 | 278 | 34 | 12- Φ25 | 818 | 400 | 270 |

| 200 | 400 | 130 | 425 | 370 | 332 | 36 | 12- Φ30 | 969 | 450 | 380 |

| 250 | 450 | 140 | 485 | 430 | 390 | 40 | 12- Φ30 | 1145 | 560 | 535 |

| 300 | 500 | 160 | 550 | 490 | 448 | 44 | 16- Φ34 | 1145 | 640 | 546 |