I. Product Introduction

II. Product Features

-

Superior Corrosion Resistance

This pneumatic diaphragm valve features a full fluorine-lined structure (PTFE/FEP/PFA) for the valve body, spool, and seat, which can resist the erosion of most strong acids, alkalis, salts, and organic solvents, ensuring long-term stable operation in corrosive environments.

-

Excellent Sealing Performance

Adopting a non-balanced single seat plug structure and high-quality NBR diaphragm with reinforced polyester fabric, this pneumatic diaphragm valve achieves VI-grade soft seal leakage performance (foam grade) in accordance with GB/T 4213 standards, realizing zero leakage of the medium and effectively preventing environmental pollution and material waste.

-

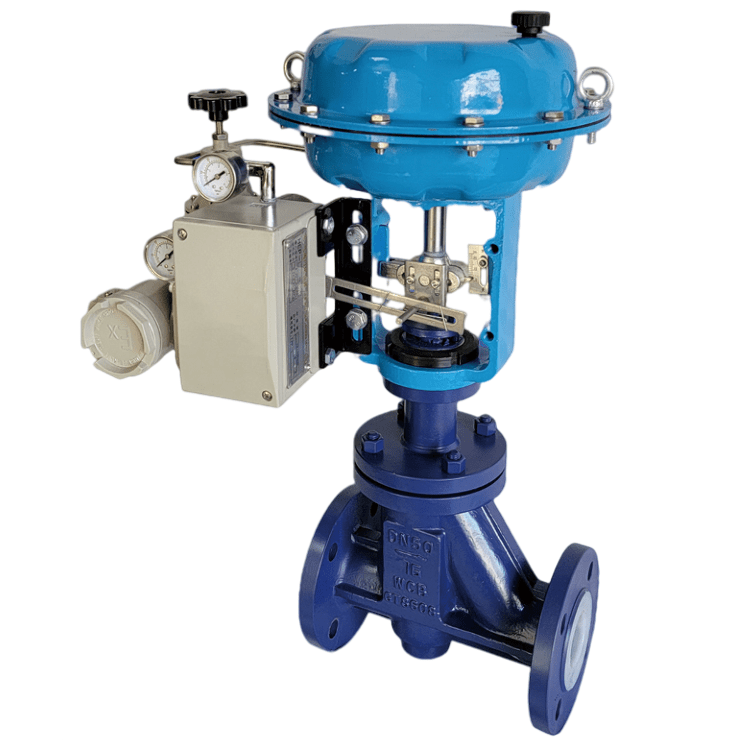

Diverse Actuator Options

This pneumatic diaphragm valve is equipped with multi-spring diaphragm actuators (PZMA-4~PZMA-7, ZHA/B series) or piston-type actuators, supporting direct and reverse action modes. With the configuration of professional accessories such as positioners, filter regulators, and solenoid valves, this pneumatic diaphragm valve can achieve high-precision flow control with an input signal of 4~20mA.DC.

-

Wide Temperature and Pressure Adaptability

The standard bonnet of this pneumatic diaphragm valve is suitable for a temperature range of -29℃ to 150℃. The optional high-quality packing (V-type PTFE packing, flexible graphite packing) and metal graphite gaskets enhance the valve’s adaptability to extreme temperatures and pressures, expanding its application scope.

-

High Control Precision

This pneumatic diaphragm valve offers three flow characteristics: linear, percentage, and quick open, with an allowable range of 30:1. The intrinsic error is as low as ±1.5%, the return difference is ≤1.5%, and the dead zone is ≤0.6%, ensuring high-precision regulation of the medium flow, pressure, and liquid level.

-

Flexible Customization and Standard Compatibility

This pneumatic diaphragm valve supports customized services for non-standard accessories and special materials. The flange dimensions comply with IEC 60534 standards, and the connection modes include FF, RF, MF, RTJ flanges, as well as SW and BW welding, which are compatible with various international and domestic pipeline standards, meeting the personalized needs of different customers.

III. Technical Data

1. Basic Specifications

| Parameter | Details |

|---|---|

| Body Type | Straight through casting globe type |

| Spool Type | Non-balanced single seat plug type |

| Nominal Size | DN20~200, NPS 3/4〞~ 8〞 |

| Nominal Pressure | PN16 ~ 100, CLASS 150LB ~ 600LB |

| Connection Mode | Flange: FF、RF、MF、RTJ; Welding: SW、BW |

| Flange Dimension | According to IEC 60534 |

| Bonnet Type | Standard type (-29℃~150℃) |

| Flow Characteristic | Linear, percentage, quick open |

| Allowable Range | 30: 1 |

| Allowable Leakage | Soft seal: VI grade (foam grade) |

| Leakage Standard | GB/T 4213 |

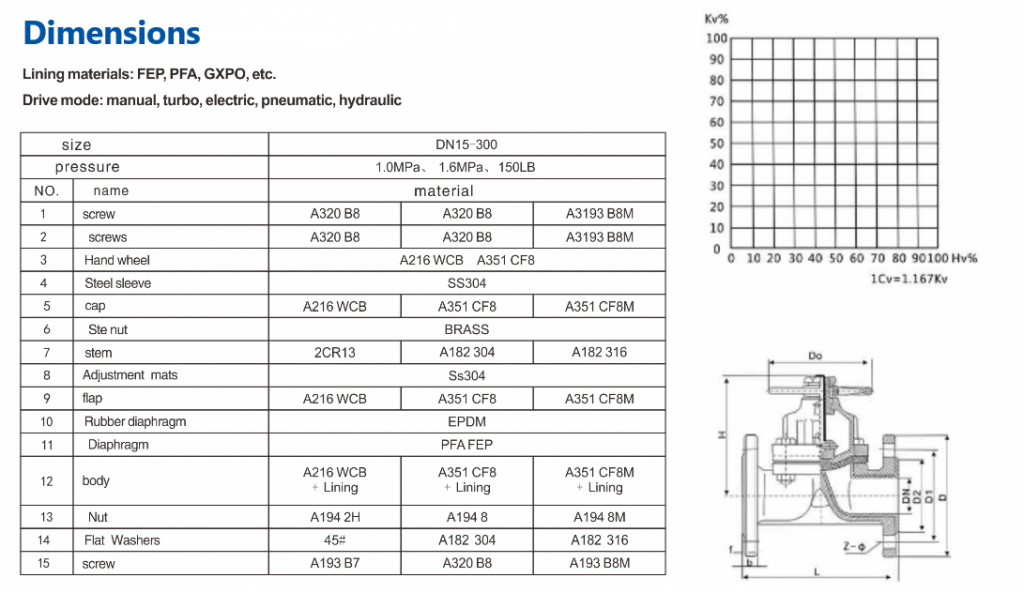

2. Material List

| Component Name | Material |

|---|---|

| Body/Bonnet | WCB/CF8/CF8M/CF3M |

| Lined Material | PTFE, FEP, PFA |

| Spool/Seat | 304/316/316L Lined PTFE/FEP/PFA |

| Packing | PTFE |

| Gasket | PTFE |

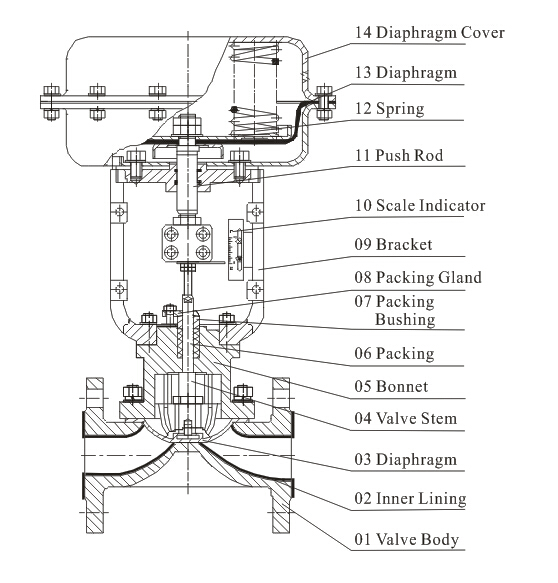

| Diaphragm Cover | Normal: Q235; Special: 304 |

| Diaphragm | NBR with reinforced polyester fabric |

| Spring | Normal: 60Si2Mn; Special: 50CrVa |

| Valve Stem | 2Cr13/17-4PH/304/316/316L |

3. Valve Performance Parameters

| Performance Index | Value (%) |

|---|---|

| Intrinsic Error | ±1.5 |

| Return Difference | ≤1.5 |

| Dead Zone | ≤0.6 |

| Difference from Beginning to End Point | ±2.5 |

| Rated Travel Difference | ≤2.5 |

4. Actuator Specifications

| Parameter | Details |

|---|---|

| Type | Pneumatic diaphragm actuator (PZMA-4~7, ZHA/B series) |

| Type Method | Multi-spring type |

| Usage | Regulating type, ON-OFF type |

| Air Supply Pressure | 140 (20~100) Kpa G; 240 (40~200) Kpa G; 280 (80~240) Kpa G |

| Connector | Air pipe connector: RC1/4 |

| Action Mode | Direct action: Pressure increase → Stem descend → Valve close; Reaction: Pressure increase → Stem ascend → Valve open |

| Input Signal | 4~20mA.DC (with positioner) |

| Lag | ≤1%FS (with positioner) |

| Linear Type | 2%FS (with positioner) |

| Environmental Temperature | -10℃~+70℃ |

| Accessories | E/P, P/P valve positioner, filter regulator, valve converter, solenoid valve, limited switch; Non-standard accessories available on customization |

5. Rated Flow Coefficient (Cv)

| Nominal Size (DN) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 |

|---|---|---|---|---|---|---|---|---|---|---|

| Percentage Cv | – | 8 | 12 | 20 | 32 | 50 | 70 | 100 | 200 | 240 |

| Linear Cv | 5 | 10 | 16 | 25 | 38 | 63 | 80 | 120 | 220 | 300 |

| Travel | 16mm | 25mm | 40mm | 60mm | – | – | – | – | – | – |

6. Actuator Effective Area & Max. Allowable Pressure Difference

| Actuator Model | Diaphragm Effective Area (Ae) cm² | Max. Allowable Pressure Difference (MPa) – Air Open (20-100KPa) | Max. Allowable Pressure Difference (MPa) – Air Close (80-240KPa) |

|---|---|---|---|

| ZHA/B-22 | 350 | 1.16 | 6.4 |

| ZHA/B-23 | 350 | 0.7 | 6.4 |

| ZHA/B-34 | 560 | 0.44 | 6.4 |

| ZHA/B-45 | 900 | 0.28 | 5.04 |

Ⅳ.The main shape and connection size