I. Product Introduction

II. Product Features

- High-Quality Material Selection

The main body, cover, and filter screen are made of high-grade stainless steel (such as SS316) and other corrosion-resistant alloys, providing excellent resistance to corrosion, high temperature, and pressure, and adapting to various corrosive media.

- Standard Flange Connection

Strictly in line with ANSI B16.5 flange dimension standards, ensuring perfect compatibility with ANSI/ASME standard pipeline systems. The connection is firm and reliable, with good sealing performance, effectively preventing fluid leakage.

- Efficient Filtration Performance

Equipped with high-precision stainless steel filter screens, the mesh total area can reach 3~4 times the nominal diameter (DN) of the pipeline, ensuring large flux and low pressure loss while efficiently intercepting impurities.

- Easy Maintenance and Operation

The structure design is user-friendly for disassembly and cleaning. The discharge port and slideway bush parts are optimized for quick removal of the filter screen and cleaning of intercepted impurities without the need for complex tools, reducing maintenance time and costs.

- Diversified Sealing Options

Providing multiple sealing materials such as PTFE, enhanced flexible graphite, and tooth profile gaskets to meet the sealing requirements of different working temperatures, pressures, and media types, ensuring long-term reliable sealing.

- Wide Operating Range

Adapting to a wide range of nominal pressures and working temperatures, with different shell materials (such as CF8, CF8M, CF3, CF3M) available for selection, meeting the needs of various industrial working conditions.

III. Technical Data

1. Administer Standards

| Category | Applicable Standards |

|---|---|

| Design and Manufacture | ANSI B16.34, JIS B2071, JIS B2081 |

| Face to Face | ANSI B16.34, JIS B2002 |

| Flange Dimension | ANSI B16.5, JIS B2212, JIS B2214 |

| Pressure-Temperature | ANSI B16.34, JIS B2017, JIS B2081 |

| Test & Check | API 598, ANSI B16.34, JIS B2003 |

2. Pressure Test

| Nominal Pressure | Shell Test | Water Seal Test | Air Seal Test |

|---|---|---|---|

| MPa (Lbf/in²) | MPa (Lbf/in²) | MPa (Lbf/in²) | |

| 150 | 3.0 (430) | 2.2 (315) | 0.4-0.7 (60-100) |

| 300 | 7.7 (1110) | 5.7 (815) | – |

3. Main Part Materials and Property

| Part Name | Material Options |

|---|---|

| Body, Cover, Discharge | WCB, WC1, WC6, WC9, C5, C12, CF8, CF8M, CF3, CF3M, SS316, SS316L |

| Slideway Bush | 1Cr13/Flexible Graphite |

| Filter Screen | Stainless Steel, Acid-proof Stainless Steel |

| Sealing Shim | PTFE, Enhanced Flexible Graphite, Asbestos, Tooth Profile Gasket |

| Performance Index | Parameter |

|---|---|

| Working Temperature | WCB: ≤425℃; WC1: ≤450℃; WC6: ≤540℃; WC9: ≤570℃; C5/C12: ≤540℃; CF8/CF8M/CF3/CF3M: ≤200℃ |

| Suitable Medium | Water, Steam, Petroleum Products, Nitric Acid, Acetic Acid, and other corrosive or non-corrosive media |

4. Main Technical Parameter

| Model | Connection Type | Nominal Pressure (MPa) | Proof Pressure (MPa) | Working Pressure (MPa) | Shell Material | Filter Screen | Mesh Total Area |

|---|---|---|---|---|---|---|---|

| SY4P-10 | Flange | 1.0 | 1.1 | 1.0 | Gray Cast Iron | Stainless Steel | 3~4DN |

| SY4P-16 | Flange | 1.6 | 1.76 | 1.6 | Spherical Cast Iron | Stainless Steel | 3~4DN |

| SY4P-25 | Flange | 2.5 | 2.75 | 2.5 | Carbon Steel | Stainless Steel | 3~4DN |

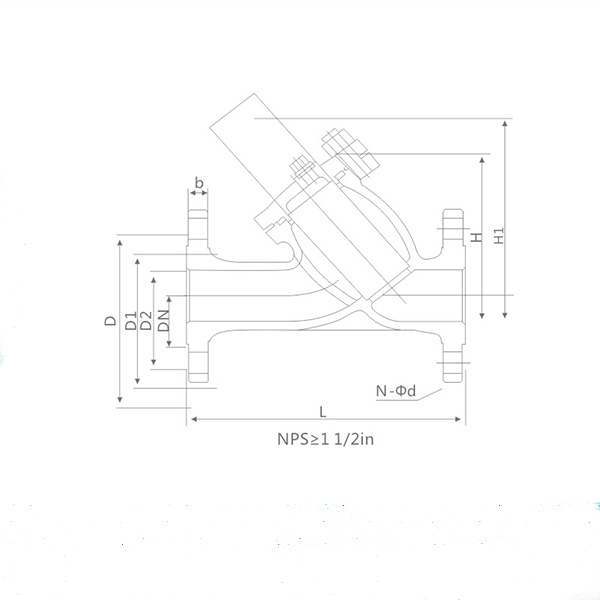

Ⅳ.The main shape and connection size

| Type | DN | d | L | 0 | C | N- Φd | 9 | t |

| 150Lb | 1/2″ | 13 | 130 | 90 | 60.3 | 4-16 | 35 | 16 |

| 3/4″ | 19 | 150 | 100 | 69.9 | 4-16 | 43 | 18 | |

| 1″ | 25.4 | 160 | 110 | 79.4 | 4-16 | 51 | 18 | |

| 11/4″ | 32 | 180 | 115 | 88.9 | 4-16 | 64 | 18 | |

| 11/2″ | 38.1 | 200 | 125 | 98.4 | 4-16 | 73 | 18 | |

| 2″ | 51 | 230 | 150 | 120.7 | 4-19 | 92 | 20 | |

| 21/2″ | 64 | 290 | 180 | 139.7 | 4-19 | 105 | 22 | |

| 3″ | 76 | 310 | 190 | 152.4 | 4-19 | 127 | 24 | |

| 4″ | 102 | 350 | 230 | 190.5 | 8-19 | 157 | 24 | |

| 300Lb | 1/2″ | 13 | 130 | 95 | 66.7 | 4-16 | 35 | 16 |

| 3/4″ | 19 | 150 | 115 | 82.6 | 4-19 | 43 | 16 | |

| 1″ | 25.4 | 160 | 125 | 88.9 | 4-19 | 51 | 18 | |

| 11/4″ | 32 | 180 | 135 | 98.4 | 4-19 | 64 | 19 | |

| 11/2″ | 38.1 | 200 | 155 | 114.3 | 4-22.5 | 73 | 21 | |

| 2″ | 51 | 230 | 165 | 127 | 8-19 | 92 | 23 | |

| 21/2″ | 64 | 290 | 190 | 149.2 | 8-22.5 | 105 | 26 | |

| 3″ | 76 | 310 | 210 | 168.3 | 8-22.5 | 127 | 29 | |

| 4″ | 102 | 350 | 255 | 200 | 8-22.5 | 157 | 32 |