I. Product Introduction

The Pneumatic Air Soft Seal Butterfly Valve is a cost-effective industrial control valve that combines a pneumatic actuator with a soft-sealed butterfly valve core. It uses compressed air as the power source to drive the butterfly plate (via the actuator) to rotate 0–90°, thereby controlling the on-off or throttling of fluid in pipelines.

Featuring a soft sealing structure (e.g., EPDM, PTFE), this valve achieves reliable bubble-tight sealing, making it widely used in low-to-medium pressure, non-corrosive (or weakly corrosive) medium systems such as water supply and drainage, HVAC, food and beverage, and environmental protection. Its compact structure, light weight, and fast response make it a mainstream choice for automatic pipeline control.

II. Product Features

- Excellent Soft Sealing Performance: Adopts high-quality soft seal materials (EPDM/PTFE/NBR) that fit closely with the butterfly plate, achieving ANSI Class VI zero leakage (no medium seepage under rated pressure), suitable for clean or food-grade media.

- Fast Pneumatic Actuation: Equipped with double-acting/single-acting pneumatic actuators, the valve completes opening/closing in 3–10 seconds. The single-acting type has spring reset (fail-open/fail-close), ensuring safety during air supply interruptions.

- Low Flow Resistance & High Efficiency: The streamlined butterfly plate design minimizes flow resistance (low pressure loss), with a high flow coefficient (Cv) that meets large-flow pipeline requirements.

- Lightweight & Easy Installation: The valve body (usually cast iron/stainless steel) is lightweight; wafer/lug connection types save installation space and simplify on-site assembly (compatible with standard flanges).

- Low Maintenance Cost: The soft seal ring is detachable and easy to replace; the actuator has few moving parts, reducing daily maintenance workload.

- Flexible Control Configuration: Supports matching with solenoid valves, positioners, and limit switches, enabling remote automatic control and signal feedback (compatible with PLC/DCS systems).

III. Technical Data

| Technical Parameter | Specification |

|---|---|

| Valve Type | Pneumatic Air Soft Seal Butterfly Valve |

| Nominal Diameter (DN) | DN40 – DN600 (1.5″ – 24″) |

| Nominal Pressure (PN) | PN1.0, PN1.6 MPa; ANSI Class 150 |

| Valve Body Material | Cast Iron (HT200), Stainless Steel (304/316) |

| Butterfly Plate Material | Carbon Steel, Stainless Steel (304/316) |

| Soft Seal Material | EPDM (-20℃~120℃), PTFE (-40℃~180℃), NBR (-10℃~80℃) |

| Sealing Grade | ANSI/FCI 70-2 Class VI (Bubble-Tight) |

| Medium Temperature Range | -40℃ – 180℃ (varies with seal material) |

| Medium Compatibility | Clean water, sewage, air, natural gas, food-grade fluids, weak acid/alkali |

| Actuator Type | Double-Acting / Single-Acting (Spring Return) |

| Actuator Air Pressure | 0.4 – 0.8 MPa (compressed air) |

| Opening/Closing Time | 3 – 10 seconds (DN40 – DN600) |

| Connection Type | Wafer, Lug, Flanged (GB/T 9113, ANSI B16.5) |

| Actuator Protection Grade | IP65 (standard) |

| Optional Accessories | Positioner, solenoid valve, limit switch, manual override |

| Service Life | ≥ 80,000 operating cycles |

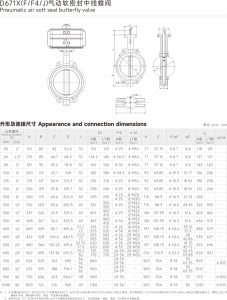

四.The main shape and connection size