I. Product Introduction

The Clamp Check Valve (Single Swing Type), especially the fully lined model, is a high-performance automatic valve designed for controlling medium flow in various industrial pipelines. It adopts a clamp connection method, which features convenient installation and disassembly, enabling quick maintenance and replacement without affecting the overall pipeline system. The single swing structure is the core design of this valve, relying on the pressure of the medium itself to drive the valve disc to open and close, thereby preventing the reverse flow of the medium.

This valve is widely applicable to different working conditions, including chemical, petroleum, pharmaceutical, food and beverage, water treatment and other industries. It can handle a variety of media such as corrosive liquids, high-temperature gases, and viscous fluids (depending on the lining material and main component materials). With its reliable sealing performance and stable operation, it effectively protects the safety of pipeline equipment, avoids damage caused by medium backflow, and ensures the smooth progress of the production process. The fully lined design further enhances the corrosion resistance of the valve, making it suitable for harsh working environments with strong corrosive media.

II. Product Features

-

Convenient Clamp Connection: The clamp connection method simplifies the installation and disassembly process. Compared with traditional flange connection, it saves time and labor, reduces the workload of on-site construction, and is easy to realize quick maintenance and replacement of the valve. At the same time, the connection is tight, which can effectively prevent medium leakage.

-

Reliable Single Swing Structure: Adopting a single valve rotary (single swing) basic structure, the valve disc opens and closes flexibly under the action of medium pressure. The flow resistance is small during opening, which does not affect the normal flow of the medium; when the medium flows backward, the valve disc can quickly close under the combined action of reverse pressure and its own weight, achieving reliable check to prevent backflow.

-

Excellent Corrosion Resistance (Fully Lined Model): The fully lined design uses high-performance corrosion-resistant materials such as FEP (F4), PFA (Soluble Polytetrafluoroethylene), and PO (Polyolefin) as the lining and seat materials. These materials have excellent chemical stability and can resist the erosion of most strong acids, alkalis, salts and organic solvents, extending the service life of the valve in corrosive working conditions.

-

Wide Range of Material Options: The valve body, valve cover, shaft, valve plate and other main components provide a variety of material options, including gray cast iron, carbon steel, stainless steel, ultra-low carbon stainless steel, etc. Users can choose the appropriate material combination according to the medium characteristics, working pressure, temperature and other working conditions to ensure the adaptability and reliability of the valve.

-

Compliance with Multiple Standards: The product is designed and manufactured in strict accordance with multiple international and domestic standards such as JB/T 8937, API 6D, HG/T 20592, ASME B16.5, API 598, and GB 13927. It has standardized structure and performance, ensuring interchangeability and compatibility with other pipeline components, and meeting the quality requirements of different regions and industries.

-

Stable Sealing Performance: The combination of high-precision valve disc and seat, as well as the reasonable structural design, ensures the excellent sealing performance of the valve. It can effectively prevent medium leakage even under high pressure and high temperature working conditions, reducing energy waste and environmental pollution.

III. Technical Data

Basic Parameters

-

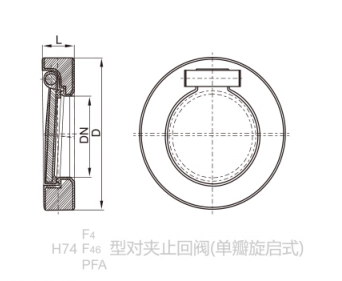

Product Type: Clamp Connection Check Valve (Fully Lined), Single Swing Type

-

Nominal Pressure: PN0.6~1.6 (MPa), ANSI 150Lb

-

Nominal Diameter: DN40~500 (mm), NPS 1½~20

-

Basic Structure Form: Single Valve Rotary (Single Swing)

-

Basic Model: H74F46, H74F4, H74PFA

Implementation Standards

-

Design and Manufacturing: JB/T 8937, API 6D

-

Structure Length: (Enterprise Standard) Q/NFL-06-99, JB/T 8937

-

Flange Size: HG/T 20592 (or as required by the contract), ASME B16.5

-

Pressure Test: API 598, GB 13927

-

Symbolization: MSS SP-25, GB 12220

-

Filling: ASME B16.34, GB/T 12252

Main Parts and Components Material Table

|

Serial Number

|

Part Name

|

Gray Cast Iron (Z)

|

Carbon Steel (C)

|

Stainless Steels (P)

|

Stainless Steels (R)

|

Ultra-Low Carbon Stainless Steel (PL)

|

Ultra-Low Carbon Stainless Steel (RL)

|

|---|---|---|---|---|---|---|---|

|

1

|

Valve Body, Valve Cover

|

HT250

|

WCB

|

CF8

|

CF8M

|

CF3

|

CF3M

|

|

2

|

Lining/Seat

|

FEP (F4), PFA (Soluble Polytetrafluoroethylene), PO (Polyolefin)

|

|||||

|

3

|

Shaft, Valve (Plate)

|

1Cr13/35

|

WCB

|

1Cr18Ni9/CF8

|

–

|

–

|

00Cr17Ni14Mo2/CF3M

|

|

4

|

Bolt (Male Component of Nut and Bolt)

|

35

|

35

|

1Cr17Ni2

|

1Cr17Ni2

|

1Cr18Ni9Ti

|

1Cr18Ni9Ti

|

|

5

|

Nut (Female Component of Nut and Bolt)

|

45

|

45

|

0Cr18Ni9

|

0Cr18Ni9

|

0Cr18Ni9

|

0Cr18Ni9

|

Ⅳ.The main shape and connection size

Main parts and components material table

| serial number | Part Name | gray cast iron | carbon steel | stainless steels | Ultra-low carbon stainless steel | ||

| Z | C | P | R | PL | RL | ||

| 1 | Valve body, valve cover | HT250 | WCB | CF8 | CF8M | CF3 | CF3M |

| 2 | Lining/seat | FEP(F4) PFA(Solublepolytetrafluoroethylene | PO(poly-terminal hydrocarbon (PET)) | ||||

| 3 | Shaft, Valve (Plate) | 1Cr13/35 WCB 1Cr18Ni9/CF8 00Cr17Ni14Mo2/CF3M | |||||

| 4 | bolt (male component of nut and bolt) | 35 | 35 | 1Cr17Ni2 | 1Cr17Ni2 | 1Cr18Ni9Ti | 1Cr18Ni9Ti |

| 5 | nut (female component of nut and bolt) | 45 | 45 | 0Cr18Ni9 | 0Cr18Ni9 | 0Cr18Ni9 | 0Cr18Ni9 |

Main connection dimensions and weight

| Nominal diameter | PN0.6(MPa) | PN1.0/1.6(MPa) | PN2.5(MPa)/ANSI300Lb | |||||||

| DN(mm) | NPS(inch) | L | D | W(kg) | L | D | W(kg | L | D | W(kg) |

| 40 | 11/2 | 26 | 80 | 1.0 | 26 | 88/73 | 1.2 | 26 | 88/73 | 1.4 |

| 50 | 2 | 26 | 90 | 1.1 | 26 | 102/92 | 1.3 | 26 | 102/92 | 1.5 |

| 65 | 21/2 | 26 | 110 | 1.3 | 26 | 122/105 | 1.6 | 26 | 122/105 | 2.0 |

| 80 | 3 | 26 | 128 | 2.5 | 26 | 138/127 | 3.0 | 26 | 138/127 | 3.8 |

| 100 | 4 | 26 | 148 | 4.8 | 26 | 158/157 | 5.4 | 26 | 162/157 | 6.3 |

| 125 | 5 | 26 | 178 | 4.8 | 26 | 188/186 | 5.4 | 26 | 188/186 | 6.3 |

| 150 | 6 | 29 | 202 | 6.5 | 29 | 212/216 | 7.8 | 29 | 218/216 | 8.8 |

| 200 | 8 | 30 | 258 | 8 | 30 | 268/270 | 10 | 30 | 278/270 | 12 |

| 250 | 10 | 30 | 312 | 15 | 30 | 320/324 | 18 | 38 | 335/324 | 20 |

| 300 | 12 | 38 | 365 | 25 | 38 | 370/381 | 30 | 51 | 395/381 | 32 |

| 350 | 14 | 44 | 415 | 36 | 44 | 430/413 | 41 | 51 | 450/413 | 45 |

| 400 | 16 | 51 | 465 | 46 | 51 | 482/470 | 55 | 51 | 505/470 | 60 |

| 450 | 18 | 60 | 520 | 68 | 60 | 532/533 | 78 | 76 | 555/533 | 85 |

| 500 | 20 | 64 | 570 | 64 | 585/584 | 90 | 83 | 615/584 | 98 | |

Table D values: PN 1.6 and 2.5 take the values of ANSI 150Lb and ANSI 300Lb, respectively.