Ⅰ.Product Introduction

The Double Spring Safety Valve is a specialized overpressure protection device designed for equipment and pipelines carrying media such as steam and water, with a maximum working temperature of less than 350℃. Its core function is to automatically release pressure when the pressure inside the protected equipment or pipeline exceeds the preset safety value, thereby preventing potential hazards caused by overpressure and ensuring the safe and stable operation of the entire system.

The flange connection dimensions of this series of safety valves comply with the Series 1 specifications in the JB/T…-94 standard, which ensures good interchangeability and compatibility with most mainstream industrial equipment and pipeline systems on the market. This design greatly facilitates the installation, maintenance and replacement of the valve, reducing the difficulty and cost of subsequent use for users.

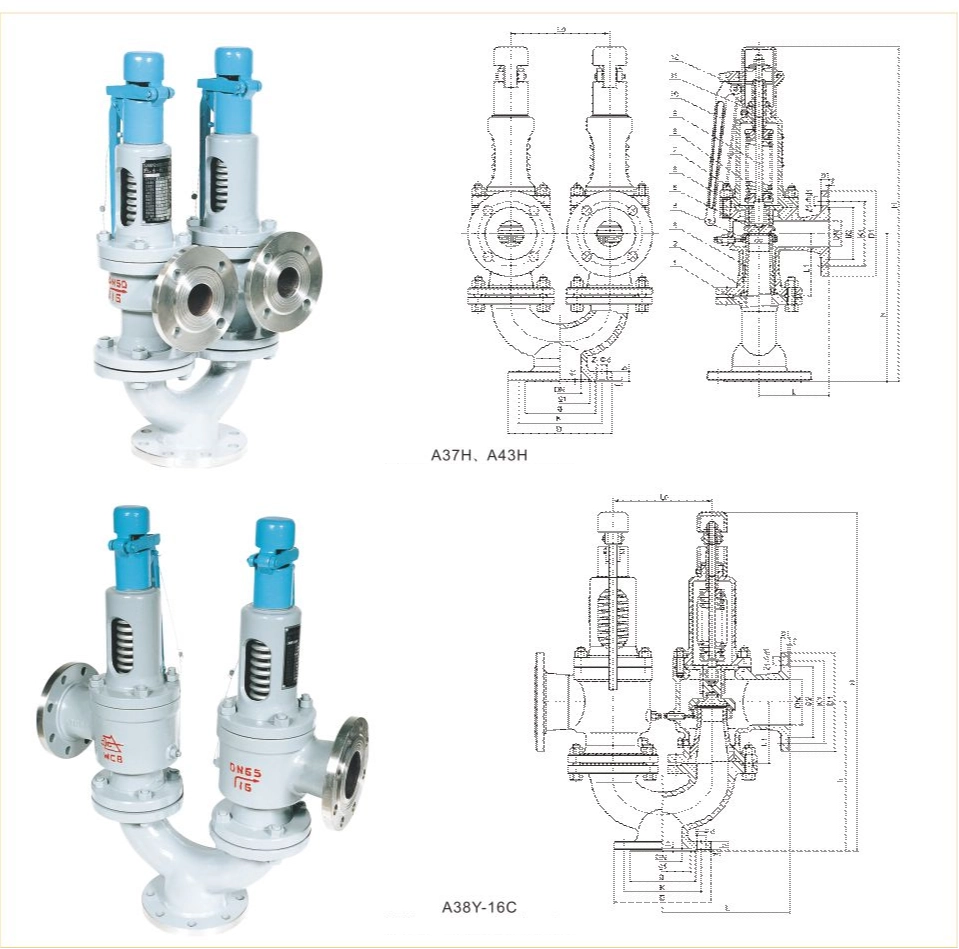

The main product series include A38Y-16C/25/40, A43H-16C/25/40 and A37H-16C/25/40. Each series of products is optimized for different application scenarios and working conditions, while maintaining the consistent core performance and structural advantages of the double spring safety valve. It should be noted that the A38Y, A43H and A37H type double safety valves are composed of two A48Y or A47Y type spring-loaded safety valves of the same specification, which are fixed on a Y-shaped joint. The nominal diameter (DN) of the double safety valve is defined as the inlet diameter of the Y-shaped joint, and the specific combination relationship between each series and the corresponding single safety valve is detailed in the relevant parameter table.

Ⅱ.Product Features

1. Reliable Overpressure Protection Performance: Adopting a double spring and double valve core structure, the valve can still maintain the basic overpressure protection function even if one of the valve cores fails, which greatly improves the safety and reliability of the equipment. The spring component is made of high-quality materials, which has excellent fatigue resistance and temperature stability, ensuring that the valve can accurately respond to pressure changes under long-term high-temperature and high-pressure working conditions.

2. Standardized and Compatible Design: The flange connection dimensions strictly comply with the JB/T…-94 Standard Series 1, which is highly compatible with mainstream industrial pipelines and equipment. Users do not need to modify the existing pipeline structure when installing, which effectively shortens the installation cycle and reduces installation costs.

3. Consistent and High-Quality Material Selection: Except for the three-way type (material: WCB), the main parts of A38Y, A43H and A37H type safety valves adopt the same high-quality materials as A47H/A48Y type spring-loaded safety valves. These materials have excellent corrosion resistance, high-temperature resistance and mechanical strength, which can adapt to the harsh working environment of steam, water and other media and extend the service life of the valve.

4. Reasonable Structural Design: The valve adopts a Y-shaped joint to connect two single safety valves, which has a compact structure and small occupied space. At the same time, the design of the Y-shaped joint ensures the uniform distribution of medium flow, making the pressure-bearing capacity of the valve more stable. In addition, the standardized structural design also facilitates the disassembly, inspection and maintenance of the valve, reducing the difficulty of daily maintenance.

5. Wide Range of Application Specifications: The product covers multiple nominal diameter specifications (DN50 to DN150), and each specification is matched with two corresponding single safety valves of appropriate models. This rich specification series can meet the overpressure protection needs of different flow rates and pressure levels of equipment and pipelines, and has strong versatility.

Ⅲ.Technical Data

3.1 Main Product Series

-

A38Y-16C/25/40

-

A43H-16C/25/40

-

A37H-16C/25/40

3.2 Material of Main Parts

For A38Y, A43H and A37H type safety valves: except for the three-way type (material: WCB), the material of other main parts is consistent with that of A47H/A48Y type spring-loaded safety valves, ensuring the consistency of product quality and performance.

3.3 Combination Relationship Between Double Safety Valve and Corresponding Single Safety Valve

The A38Y, A43H and A37H type double safety valves are composed of two A48Y or A47Y type safety valves of the same specification. The specific combination (nominal diameter DN) is shown in the following table:

|

A38Y Type (DN)

|

Relevant A48Y Type (DN)

|

A43Y Type (DN)

|

Relevant A47Y Type (DN)

|

A37Y Type (DN)

|

Relevant A47Y Type (DN)

|

|---|---|---|---|---|---|

|

50

|

32×2

|

50

|

32×2

|

50

|

32×2

|

|

80

|

50×2

|

80

|

50×2

|

80

|

65×2

|

|

100

|

65×2

|

100

|

80×2

|

100

|

80×2

|

|

125

|

100×2

|

125

|

100×2

|

–

|

–

|

|

150

|

125×2

|

150

|

125×2

|

150

|

125×2

|

3.4 Key Technical Parameters

-

Applicable Medium: Steam, water, etc.

-

Maximum Working Temperature: < 350℃

-

Flange Connection Standard: JB/T…-94 (Series 1)

-

Nominal Pressure Rating: 16C, 25, 40 (consistent with the product series)

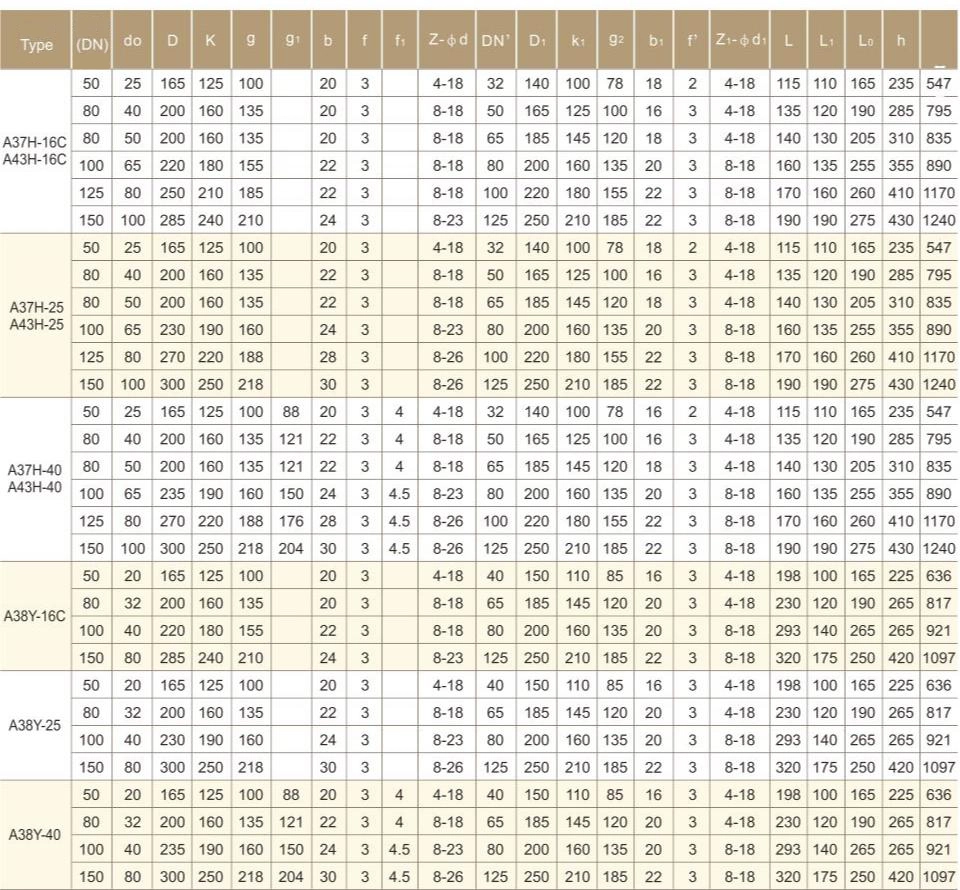

Ⅳ.The main shape and connection size