I. Product Introduction

The WYE 3-piece lever operated ball valve is a high-performance fluid control device designed for precise on-off control in various industrial and commercial applications. Crafted with premium materials such as SS304 (CF8), SS316 (CF8M), and WCB, this valve features a 2-way flow design, anti-blowout stem structure, and flange connection, ensuring reliable operation and long service life.

With a size range covering 1/2″ ~ 12″ (DN15 ~ DN300), it is widely compatible with multiple media including water, air, steam, gas, and oil. Specifically engineered to adapt to harsh working conditions with a temperature range of -29℃ to 180℃ and a working pressure of 1.6~6.4MPa, this valve is an ideal choice for industries such as food & beverage, water & wastewater treatment, ultra-pure water systems, desalination plants, chemicals, textiles, pharmaceuticals, pulp & paper, mining, as well as boiler and power generation industries. The lever-operated design enables quick and effortless manual operation, improving work efficiency in on-site control scenarios.

II. Product Features

-

Superior Material Selection: Available in SS304 (CF8), SS316 (CF8M) stainless steel and WCB carbon steel, offering excellent corrosion resistance, high temperature resistance, and mechanical strength. SS304 and SS316 materials are particularly suitable for corrosive media and food-grade applications, while WCB provides cost-effectiveness for general industrial use.

-

Anti-Blowout Stem Design: Equipped with an anti-blowout stem structure that effectively prevents the stem from blowing out due to excessive internal pressure, enhancing operational safety and avoiding potential fluid leakage accidents.

-

3-Piece Split Structure: The 3-piece design allows for easy disassembly, inspection, maintenance, and replacement of internal components (such as valve seats and balls) without removing the entire valve from the pipeline, significantly reducing maintenance time and labor costs.

-

Reliable Sealing Performance: Adopts high-quality PTFE sealing material, which boasts excellent chemical stability, low friction coefficient, and good sealing performance. It ensures zero leakage under rated pressure and temperature, guaranteeing the integrity of the fluid system.

-

Convenient Lever Operation: The lever-operated manual control mode enables fast on-off switching with minimal effort. The SS201 stainless steel handle is sturdy and durable, resistant to corrosion and wear, ensuring comfortable and reliable operation even in harsh environments.

-

Wide Compatibility: Covers a broad size range from 1/2″ to 12″ (DN15 to DN300) and is compatible with multiple media types. Flange connection (conforming to standard specifications) ensures stable and secure installation, adapting to various pipeline systems.

III. Technical Data

|

Parameter Item

|

Specification Details

|

|---|---|

|

Product Model

|

WYE 3-Piece 2-Way Lever Operated Ball Valve

|

|

Size Range

|

1/2″ ~ 12″ (DN15 ~ DN300)

|

|

Applicable Medium

|

Water, Air, Steam, Gas, Oil, etc.

|

|

Working Temperature

|

-29℃ ~ 180℃

|

|

Working Pressure

|

1.6 ~ 6.4MPa

|

|

Connection Type

|

Flanged

|

|

Sealing Material

|

PTFE

|

|

Handle Material

|

SS201

|

|

Valve Body Material

|

SS316 (CF8M), SS304 (CF8), WCB

|

|

Operation Mode

|

Lever Operated (Manual)

|

|

Flow Direction

|

2-Way

|

|

Key Structure

|

3-Piece Split Body, Anti-Blowout Stem

|

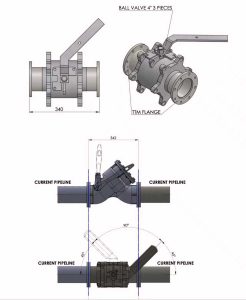

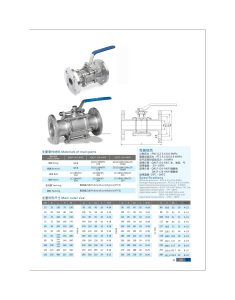

Ⅳ.The main shape and connection size