一、Product Introduction

The WYE Multi Turn Stainless Steel Motorized Actuator Globe Valve is a high-performance fluid control device integrating advanced electric actuation technology and premium material craftsmanship. Designed for precise regulation and on-off control of various media in industrial pipelines, this valve takes stainless steel (SS304/316/316L) as the core body material, supplemented by cast iron options, to meet the corrosion resistance requirements of different working environments. Covering a wide size range from 1/2” to 12”, it is compatible with operating pressure up to PN1.6MPa, making it suitable for water supply and drainage, petroleum, chemical, food and beverage, pharmaceutical, and HVAC systems.

Equipped with two control modes (On-Off Type and Regulation Type), the valve can flexibly adapt to automatic control needs such as system switching and flow adjustment. The optional voltage range includes DC24V, AC24V, AC110V, AC220V, and supports customization of DC12V and AC380V, ensuring seamless integration with various industrial control systems. With multiple connection methods (Thread, Flange, Tri Clamp, Welded, Socket) and temperature-resistant sealing materials (PTFE/PPL), it provides reliable sealing performance and installation flexibility, effectively reducing leakage risks and improving the stability and service life of the entire pipeline system.

二、Product Features

- Superior Material Performance: The valve body offers multiple material options (Cast Iron, SS304, SS316, SS316L). Stainless steel variants feature excellent corrosion resistance, high-temperature resistance, and wear resistance, ensuring stable operation in harsh media environments (such as corrosive chemicals, high-purity fluids).

- Dual Control Modes: Supports both On-Off Type (for rapid opening/closing of pipelines) and Regulation Type (for precise adjustment of flow, pressure, and other parameters), meeting diverse control requirements of industrial automation systems.

- Flexible Voltage Configuration: Standard voltage options include DC24V, AC24V, AC110V, and AC220V; DC12V and AC380V can be customized according to customer needs, adapting to different power supply systems and control panel configurations.

- Wide Temperature Adaptability: Sealing materials are available in PTFE (operating temperature 0~180℃) and PPL (operating temperature 0~230℃), covering most industrial temperature ranges and ensuring reliable sealing without deformation under extreme temperature conditions.

- Versatile Connection Methods: Offers Thread, Flange, Tri Clamp, Welded, and Socket connections, matching different pipeline installation standards and scenarios (such as sanitary pipelines requiring Tri Clamp, high-pressure pipelines using Flange/Welded connections).

- Comprehensive Size Coverage: Size range from 1/2” to 12” meets the needs of small-diameter precision control and large-diameter high-flow applications, with strong versatility across industries.

- Stable Pressure Bearing Capacity: Designed for PN1.6MPa operating pressure, with a robust body structure and precise machining, ensuring safe operation without leakage under rated pressure and reducing maintenance costs.

三、Technical Data

| Parameter Category | Specific Specifications |

|---|---|

| Product Model | WYE Multi Turn Stainless Steel Motorized Actuator Globe Valve |

| Keyword | Stainless steel motorized globe valve |

| Size Range | 1/2” – 12” |

| Operating Pressure | PN1.6MPa |

| Control Mode | On Off Type, Regulation Type |

| Optional Voltage | Standard: DC24V, AC24V, AC110V, AC220V; Customizable: DC12V, AC380V |

| Body Material | Cast Iron, SS304, SS316, SS316L |

| Sealing Material | PTFE (operating temperature: 0~180℃), PPL (operating temperature: 0~230℃) |

| Connection Type | Thread, Flange, Tri Clamp, Welded, Socket |

| Actuation Type | Multi Turn Motorized Actuator |

| Operating Medium | Water, Oil, Gas, Chemicals, Food-grade Fluids, High-purity Media (depending on material) |

| Sealing Performance | Zero leakage (complying with industrial sealing standards) |

| Service Life | ≥100,000 cycles (under rated working conditions) |

| Protection Grade | IP65 (standard), IP67 (optional) |

| Installation Orientation | Vertical/Horizontal (no restriction, recommended vertical for optimal performance) |

| Execution Standard | Body: GB/T 12224, ANSI B16.34; Flange: GB/T 9113, ANSI B16.5; Thread: NPT, BSPT |

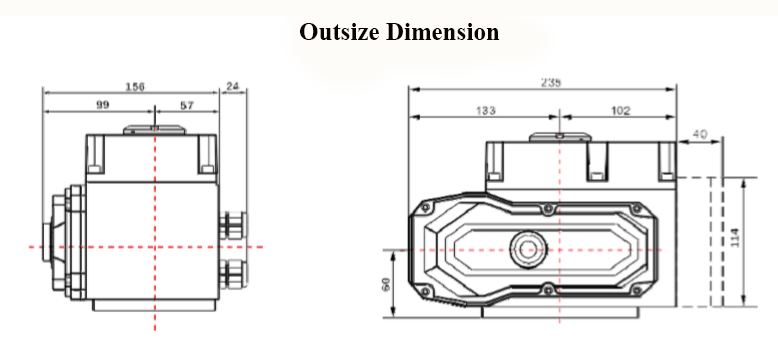

四、主体形状和连接尺寸