一、Product Introduction

The Multi Turn Electric Actuator Knife Gate Valve is an integrated automatic fluid control device, combining a high-performance multi-turn electric actuator with a precision-engineered knife gate valve. It is specifically designed for on-off control of media containing particles, slurry, pulp, or high-viscosity fluids in industrial pipelines, and is widely applied in industries such as mining, chemical processing, sewage treatment, pulp and paper, and power generation.

This product realizes automated pipeline control through the multi-turn electric actuator, which drives the gate plate to lift precisely, achieving reliable opening and closing of the valve. It supports flexible customization (e.g., special temperature adaptation, explosion-proof protection, extended working time) to match diverse harsh working conditions. With rich signal compatibility and stable performance, it effectively reduces manual operation costs and improves the safety and efficiency of pipeline systems.

二、Product Features

-

Flexible Power Supply OptionsSupports conventional power supplies (single-phase 220V, three-phase 380V) and special custom voltages (three-phase 400V, 415V, 660V, compatible with 50Hz/60Hz), adapting to different regional power grid standards.

-

Strong Environmental AdaptabilityThe standard working environment covers a temperature range of -20 ~ +60℃ (customizable for special temperature scenarios) and a relative humidity of 95% (at 25℃), ensuring stable operation in humid, high/low-temperature environments.

-

Diverse Signal Compatibility

- Input signals: Supports 4mA-20mA DC analog signals (input impedance 250Ω), 24V DC on-off signals, and optional Profibus-DP/MODBUS bus communication.

- Output signals: Equipped with 4mA-20mA DC output (load resistance ≤750Ω) and 6 groups of passive contacts; bus communication is also optional, enabling seamless connection with industrial control systems.

-

Customizable Protection LevelsThe standard protection level is IP55 (for outdoor use); IP65, IP67, IP68 can be customized for special orders, and explosion-proof types are available, suitable for outdoor, dusty, or explosive hazardous areas.

-

Adjustable Working SystemThe standard short-time working system is 10 minutes; 15-60 minutes can be customized, meeting the needs of frequent or long-duration valve operation scenarios.

-

Optimized for Special MediaThe knife gate valve structure is suitable for media containing particles, slurry, or high viscosity, with a sharp gate plate that cuts through media smoothly, avoiding blockage and ensuring tight sealing.

-

Integrated & Easy InstallationThe integrated design of the multi-turn electric actuator and knife gate valve simplifies on-site installation and debugging, realizing automatic control without additional matching components.

三、Technical Data

| Parameter Category | Specific Specifications |

|---|---|

| Product Basic Information | |

| Product Name | Multi Turn Electric Actuator Knife Gate Valve |

| Electric Actuator Technical Parameters | |

| Power supply | Conventional: single phase 220V, three-phase 380V; Special: three-phase 400V, 415V, 660V (50Hz, 60Hz) |

| Working environment | Ambient temperature: -20 ~ +60℃ (special temperature environment can be customized); Relative humidity: 95% (at 25℃) |

| Input signals | Analog quantity: 4mA-20mA DC (input impedance 250Ω); On-off quantity: active 24V DC; Profibus-DP/MODBUS (optional) |

| Output signals | 4mA-20mA DC (load resistance 750Ω or less); 6 groups of passive contacts; Profibus-DP or MODBUS (optional) |

| Protection level | Outdoor type and explosion-proof type: IP55 (IP65, IP67, IP68 can be provided for special order) |

| Working system | Short time: 10 minutes (15-60 minutes for special order) |

| Knife Gate Valve Body Technical Parameters | |

| Size Range | 1/2” – 24” (customizable according to demand) |

| Operating Pressure | PN1.0MPa, PN1.6MPa (standard) |

| Body Material | Cast Iron, SS304, SS316, SS316L |

| Sealing Material | EPDM (0~80℃), PTFE (0~180℃) |

| Applicable Medium | Slurry, sewage, pulp, particles-containing fluids, low-viscosity chemicals |

| Connection Type | Flange, Wafer, Lug (optional) |

| Sealing Performance | Bubble-tight sealing (complying with industrial valve sealing standards) |

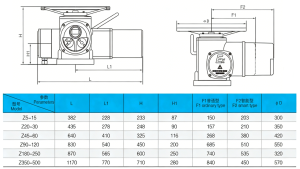

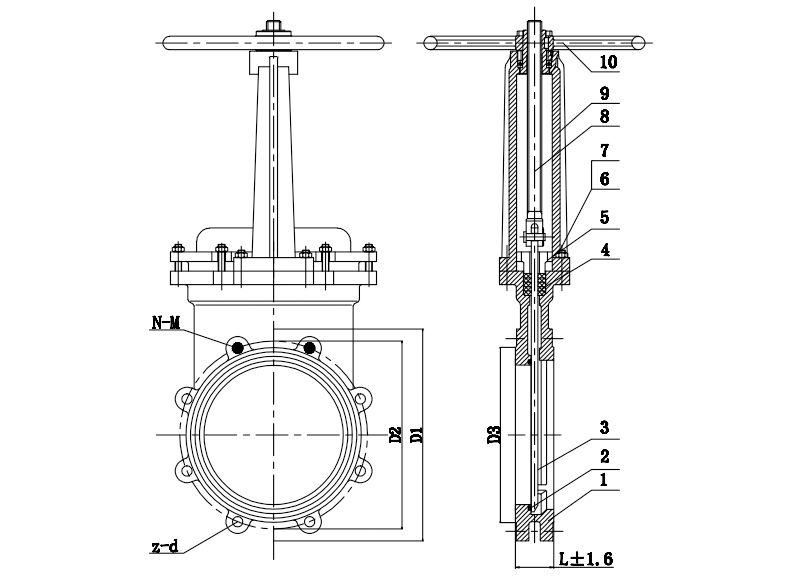

四.The main shape and connection size

| PZ73W-150LBP | |||||||

| NPS | DN | D1 | D2 | D3 | N-M | z-d | L |

| 4” | 100 | 229 | 190.5 | 157 | 2-M5/8-11 | 6-Φ19 | 51 |