I. Product Introduction

The Flange Connection Discharge Ball Valve (fully Lined) is a high-performance industrial valve specifically designed for the safe and efficient discharge of various media, including corrosive, abrasive, viscous, and toxic substances. It integrates the advantages of flange connection—such as reliable sealing, easy installation and maintenance—and full lining technology, which provides superior corrosion and wear resistance. This valve is widely used in key industries such as chemical engineering, petrochemicals, pharmaceuticals, food and beverage, pulp and paper, water treatment, and mining, playing a crucial role in regulating and controlling the flow of media in pipelines.

The core design of the valve focuses on solving the problems of media corrosion and wear on traditional valves, ensuring long-term stable operation even in harsh working conditions. The flange connection adopts international standards (such as ANSI, DIN, JIS), making it compatible with most industrial pipelines, thus reducing the difficulty of equipment matching and replacement. The fully lined structure covers the inner surface of the valve body, ball, and seat with high-performance corrosion-resistant materials, effectively isolating the metal matrix from the medium and avoiding valve failure caused by corrosion, erosion, or scaling.

II. Product Features

-

Excellent Corrosion & Wear Resistance: The valve is fully lined with high-quality materials such as PTFE (Polytetrafluoroethylene), PFA (Perfluoroalkoxy Alkane), FEP (Fluorinated Ethylene Propylene), or ETFE (Ethylene-Tetrafluoroethylene Copolymer). These lining materials have excellent chemical stability, being resistant to almost all strong acids, bases, oxidants, and organic solvents. Meanwhile, the lining surface is smooth and wear-resistant, which can effectively withstand the scouring of abrasive media (such as slurries containing solid particles), extending the service life of the valve.

-

Reliable Sealing Performance: The valve adopts a floating ball or fixed ball structure, combined with a lined seat that fits closely with the ball. The sealing pair (ball and seat) is made of wear-resistant and corrosion-resistant lining materials, ensuring zero leakage even under high pressure and high temperature conditions. The flange connection is equipped with high-quality gaskets (such as PTFE gaskets, metal wound gaskets) to further enhance the sealing reliability of the valve at the connection part, preventing media leakage and ensuring operational safety.

-

Smooth Flow & Low Pressure Loss: The inner cavity of the fully lined valve is designed to be streamlined, with no dead corners or obstacles. The smooth lining surface minimizes the friction resistance of the medium during flow, enabling the valve to have a large flow capacity and low pressure loss. This not only improves the efficiency of the pipeline system but also reduces energy consumption, which is particularly suitable for occasions requiring large flow discharge.

-

Easy Operation & Maintenance: The flange connection design allows the valve to be quickly installed and disassembled without damaging the pipeline or the valve itself, facilitating on-site maintenance and replacement. The valve stem adopts a multi-layer sealing structure, which not only prevents medium leakage along the stem but also reduces the friction between the stem and the packing, making the opening and closing operation light and flexible. In addition, the key components (such as the ball, seat, and lining) have a modular design, which is easy to replace and reduces maintenance costs.

-

Wide Application Range: The valve can be customized with different lining materials, nominal diameters, and pressure ratings according to the characteristics of the medium (such as corrosion, temperature, viscosity) and working conditions (such as pressure, temperature). It is suitable for handling various media, including strong corrosive media (such as sulfuric acid, hydrochloric acid, nitric acid), organic solvents (such as acetone, ethanol), viscous media (such as resin, syrup), and abrasive slurries (such as coal slurry, ore slurry), meeting the needs of different industries.

-

Stable Mechanical Performance: The valve body is made of high-strength carbon steel, stainless steel, or alloy steel, which has excellent mechanical strength and pressure-bearing capacity, ensuring that the valve can work stably under high pressure and harsh environmental conditions. The combination of the metal valve body and the lining material not only guarantees the structural strength of the valve but also solves the problem of corrosion resistance, achieving a perfect balance between mechanical performance and corrosion resistance.

III. Technical Data

|

Item

|

Technical Specification

|

|---|---|

|

Valve Type

|

Flange Connection Discharge Ball Valve (Fully Lined), Floating Ball / Fixed Ball

|

|

Nominal Diameter (DN)

|

DN15 ~ DN600 (1/2″ ~ 24″)

|

|

Nominal Pressure (PN)

|

PN10 ~ PN40; Class 150 ~ Class 300

|

|

Lining Material

|

PTFE, PFA, FEP, ETFE, PVDF

|

|

Valve Body Material

|

Carbon Steel (WCB), Stainless Steel (CF8, CF8M), Alloy Steel

|

|

Ball Material

|

Stainless Steel Lined PTFE/PFA/FEP/ETFE; Carbon Steel Lined PTFE/PFA/FEP/ETFE

|

|

Seat Material

|

PTFE, PFA, FEP, ETFE (with reinforcement ring if necessary)

|

|

Valve Stem Material

|

Stainless Steel (2Cr13, 316L), Hastelloy (for severe corrosion conditions)

|

|

Operating Temperature Range

|

-20°C ~ +180°C (PTFE); -20°C ~ +260°C (PFA/FEP/ETFE) (subject to lining material)

|

|

Operating Medium

|

Strong acids, bases, oxidants, organic solvents, viscous media, slurries (with solid particles), etc.

|

|

Connection Standard

|

Flange: ANSI B16.5, DIN EN 1092-1, JIS B2220, GB/T 9113

|

|

Sealing Class

|

ANSI Class VI (Zero Leakage)

|

|

Operating Mode

|

Manual, Pneumatic Actuation, Electric Actuation, Hydraulic Actuation

|

|

Flow Coefficient (Cv)

|

Depends on nominal diameter, typically 10 ~ 1200 (specific values available upon request)

|

|

Pressure Test Standard

|

API 598, GB/T 13927

|

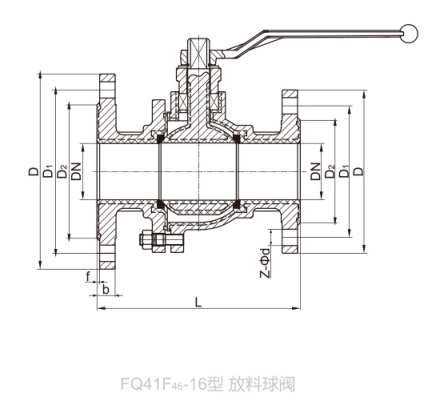

Ⅳ.The main shape and connection size

| Nominal diameter

DN (mm) |

Standard value (unit: mm) | ||||||

| L | D | D1 | D₂ | f | b | Z-Φd | |

| PN1.0MPa | |||||||

| 25/40 | 140 | 115/130 | 85/10 | 68/80 | 3/3.5 | 18/18 | 4-Φ14/4-Φ14 |

| 25/50 | 140 | 115/140 | 85/110 | 68/90 | 3/4 | 18/18 | 4-Φ14/4-Φ14 |

| 32/50 | 155 | 140/140 | 100/110 | 78/80 | 3.5/4 | 18/18 | 4-Φ18/4-Φ14 |

| 32/65 | 155 | 140/160 | 100/130 | 78/110 | 3.5/4 | 18/18 | 4-Φ18/4-Φ14 |

| 40/80 | 170 | 150/190 | 110/150 | 88/128 | 3.5/4 | 18/18 | 4-Φ18/4-Φ18 |

| 40/100 | 170 | 150/210 | 110/170 | 88/148 | 3.5/4.5 | 18/18 | 4-Φ18/4-Φ18 |

| 40/125 | 170 | 150/240 | 110/200 | 88/178 | 3.5/4.5 | 18/18 | 4-Φ18/8-Φ18 |

| 50/80 | 190 | 165/190 | 125/150 | 102/128 | 4/4 | 18/20 | 4-Φ18/4-Φ18 |

| 50/100 | 190 | 165/210 | 125/170 | 102/148 | 4/4.5 | 18/20 | 4-Φ18/4-Φ18 |

| 50/125 | 190 | 165/240 | 125/200 | 102/178 | 4/4.5 | 18/20 | 4-Φ18/8-Φ18 |

| 50/150 | 190 | 165/265 | 125/225 | 102/202 | 4/4.5 | 18/20 | 4-Φ18/8-Φ18 |

| 65/100 | 210 | 185/210 | 145/170 | 122/148 | 4/4.5 | 18/20 | 4/8-Φ18/4-Φ18 |

| 65/125 | 210 | 185/240 | 145/200 | 122/178 | 414.5 | 18/20 | 4/8-Φ18/4-Φ18 |

| 80/100 | 245 | 200/210 | 160/170 | 138/148 | 4/4.5 | 20/20 | 8-Φ18/4-Φ18 |

| 80/125 | 245 | 200/240 | 160/200 | 138/178 | 4/4.5 | 20/20 | 8-Φ18/8-Φ18 |

| 80/150 | 245 | 200/265 | 160/225 | 138/202 | 4/4.5 | 20/20 | 8-Φ18/8-Φ18 |

| 100/125 | 280 | 220/240 | 180/200 | 158/178 | 4.5/4.5 | 20/22 | 8-Φ18/8-Φ18 |

| 100/150 | 280 | 220/265 | 180/225 | 158/202 | 4.5/4.5 | 20/22 | 8-Φ18/8-Φ18 |

| 100/200 | 280 | 220/320 | 180/280 | 158/258 | 4.5/5 | 20/22 | 8-Φ18/8Φ18 |

| 125/150 | 320 | 250/265 | 210/225 | 188/202 | 4.5/4.5 | 22/22 | 8-Φ18/8-Φ18 |

| 125/200 | 320 | 250/320 | 210/280 | 188/258 | 4.5/5 | 22/24 | 8-Φ18/8-Φ18 |

| 125/250 | 320 | 250/375 | 210/335 | 188/312 | 4.5/5 | 22/26 | 8-Φ18/12-Φ18 |

| 150/200 | 360 | 285/320 | 240/280 | 212/258 | 4.5/5 | 22/24 | 8-Φ22/8-Φ18 |

| 150/250 | 360 | 285/375 | 240/335 | 212/312 | 4.5/5 | 22/26 | 8-Φ22/12-Φ18 |