I. Product Introduction

The pneumatic union PVC ball valve is a specialized fluid control device that integrates the corrosion resistance of PVC (polyvinyl chloride) material, the easy installation feature of the union structure, and the high-efficiency automation of the pneumatic actuator. With a spherical closure element (ball) as its core control component, this valve uses compressed air as the power source to drive the pneumatic actuator, thereby achieving rapid on-off control of fluid media.

Widely applicable in non-high-pressure industrial and civil fields, this valve finds its uses in water treatment (drinking water and sewage treatment), chemical industry (low-concentration acid and alkali solutions), food and beverage processing (non-high-temperature material transportation), agricultural irrigation, and aquaculture, among others. It is particularly suitable for occasions requiring corrosion resistance, easy installation and maintenance, and automatic control of fluid circuits, and can stably handle various neutral and weakly corrosive liquid media.

II. Product Features

-

Superior Corrosion ResistanceThe valve body, ball, and union joint components are all made of high-quality UPVC (unplasticized polyvinyl chloride) or CPVC (chlorinated polyvinyl chloride) materials. UPVC is suitable for general corrosive media, while CPVC can withstand higher temperatures and stronger corrosiveness. Both materials exhibit excellent resistance to neutral salts, low-concentration acids (e.g., dilute sulfuric acid, hydrochloric acid), alkalis (e.g., dilute sodium hydroxide), and organic solvents, eliminating the common rust and corrosion issues associated with metal valves.

-

Union Structure for Easy Installation and MaintenanceEquipped with standard union joints at both inlet and outlet ends, the valve can be quickly connected to PVC pipelines via socket welding or threaded connection without the need for pipeline cutting during installation. For maintenance or replacement purposes, simply loosen the union nuts to directly remove the valve from the pipeline without damaging the entire piping system, thus significantly reducing maintenance time and labor costs.

-

High-Efficiency Pneumatic ActuatorThe valve is matched with a high-performance single-acting (spring return) or double-acting pneumatic actuator, capable of completing on-off switching within 1–5 seconds. The actuator is sensitive and stable, and can be connected to automatic control systems (such as PLC) to realize remote centralized control, reducing manual operations and improving production efficiency and safety.

-

Excellent Sealing Performance and Low Flow ResistanceBoth the ball and valve seat undergo precision machining. The valve seat is made of elastic materials such as EPDM (ethylene propylene diene monomer) or FKM (fluororubber), providing excellent sealing performance and ensuring zero leakage under rated working conditions. The full-bore spherical structure features a smooth inner cavity with a flow resistance coefficient as low as 0.1–0.3, which can minimize fluid pressure loss and ensure unimpeded medium transportation.

-

Lightweight and Cost-EffectivePVC material is lightweight (with a density approximately 1/5 that of metals), facilitating transportation and installation while reducing the load on pipeline support structures. Compared with stainless steel valves of the same specification, it offers lower manufacturing and subsequent maintenance costs, boasting a distinct cost advantage in large-scale application scenarios.

III. Technical Specifications

| Parameter Item | Specification Details |

|---|---|

| Valve Material | Valve body/ball/union joint: UPVC, CPVC; Valve seat: EPDM, FKM; Actuator housing: Aluminum alloy (anodized) |

| Nominal Diameter | DN15–DN100 (1/2″ – 4″); Customized special specifications available |

| Nominal Pressure | UPVC: PN10 (1.0MPa); CPVC: PN16 (1.6MPa) |

| Operating Temperature | UPVC: 0℃ – 60℃; CPVC: -15℃ – 95℃ |

| Applicable Media | Neutral liquids (water, tap water), low-concentration acid and alkali solutions, food-grade media (compliant with FDA certification when food-grade seals are used), non-flammable and non-explosive organic solvents |

| Actuator Type | Double-acting pneumatic actuator; Single-acting pneumatic actuator (spring return, fail-open or fail-close options available) |

| Driving Pressure | 0.4–0.8MPa (dry and oil-free compressed air is recommended) |

| Switching Time | 1–5 seconds (varies with valve diameter and actuator model; DN15–DN50: 1–2 seconds; DN65–DN100: 3–5 seconds) |

| Sealing Performance | ISO 5208 Class VI (zero leakage under rated pressure and temperature) |

| Connection Type | Union type socket connection (compatible with standard PVC pipes); Threaded connection (NPT, BSP) optional for union ends |

| Control Signal | On-off signal (standard); 4–20mA current signal optional (with intelligent positioner for regulation) |

| Protection Class | Actuator: IP65; IP67 optional for outdoor or humid environments |

| Certification | ISO9001 quality management system certification; FDA certification (for food-grade applications); CE certification |

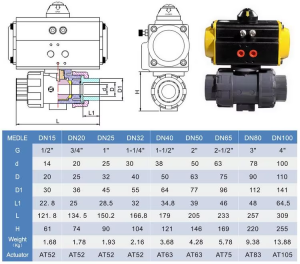

四.The main shape and connection size