I. Product Introduction

The Pneumatic Globe Valve is a precision linear flow control device integrating a high-performance pneumatic actuator with a sophisticated globe valve body, widely applied in industrial pipeline systems for accurate on-off control and throttling regulation of various media. It is specifically designed to handle liquids, gases, steam, and weakly corrosive fluids, making it a core component in industries such as petroleum, chemical engineering, power generation, water treatment, pharmaceutical, and food processing.

Featuring a unique plug-and-seat structure, the valve achieves precise flow adjustment by driving the plug to move linearly along the valve seat through the pneumatic actuator, enabling stable control of medium flow, pressure, and temperature in industrial processes. Its robust design ensures reliable operation even under harsh working conditions such as high pressure, high temperature, and frequent switching, effectively optimizing process efficiency, reducing energy consumption, and ensuring system operational safety. Whether in small-diameter precision control pipelines or large-scale industrial transmission systems, the pneumatic globe valve provides consistent, automated, and high-precision flow control solutions to meet strict industrial process requirements.

II. Product Features

- Precise Flow Regulation Performance: Adopts a linear flow characteristic design, with the plug and valve seat forming a precise matching structure that realizes stepless adjustment of medium flow (0–100% flow control range). Equipped with an optional intelligent pneumatic positioner, it can accept 4–20 mA analog signals to achieve high-precision proportional control, with flow control accuracy up to ±1%, ensuring stable and accurate adjustment of industrial process parameters.

- Reliable Pneumatic Actuation System: Configured with high-thrust pneumatic actuators, available in double-acting and single-acting (spring return) types. The double-acting type realizes rapid opening and closing with a response time of 1–4 seconds (varies by valve size), while the single-acting type provides fail-safe protection—automatically resetting to preset open/closed position via spring force when air supply is interrupted, effectively avoiding process accidents and improving system reliability.

- Excellent Sealing and Wear Resistance: Adopts dual sealing design options for different working conditions: flexible sealing (PTFE, EPDM, FKM) achieves ANSI Class VI zero leakage, suitable for media with strict sealing requirements; metal-to-metal rigid sealing (304/316 stainless steel, alloy steel) has strong wear resistance and high-temperature resistance, adapting to high-pressure, high-temperature, and abrasive media scenarios. The sealing surface undergoes precision grinding and polishing, ensuring long-term sealing stability and reducing maintenance frequency.

- Durable and Corrosion-Resistant Construction: Valve body and internal components are made of high-quality materials, including carbon steel (WCB), stainless steel (304/316/316L), and alloy steel (WC6/WC9), selectable according to medium properties and working pressure. The outer surface is treated with anti-corrosion coating (epoxy resin, electrostatic spraying) to resist harsh environmental erosion, while internal components adopt anti-corrosion and wear-resistant treatments, extending the valve’s service life to over 80,000 cycles under normal working conditions.

- Easy Installation and System Compatibility: Features compact structure and standardized design, with flange, threaded, and welded connection modes available, compatible with international standards (GB, DIN, ANSI, JIS) for seamless integration into various pipeline systems. The actuator adopts NAMUR standard interface, enabling easy matching with solenoid valves, limit switches, pressure gauges, and other auxiliary components, supporting remote control and real-time status monitoring, and adapting to automated control system integration needs.

- Wide Application Adaptability: Suitable for media such as water, oil, natural gas, steam, acid-base solutions, and organic solvents, with nominal diameter covering DN10–DN600 and nominal pressure ranging from PN10–PN320 (Class 150–Class 1500), adapting to low-temperature, high-temperature, low-pressure, and high-pressure working environments (-60°C–550°C). It complies with ISO, API, and other international standards, meeting the needs of various industrial fields for precision flow control.

III. Technical Data

| Technical Parameter | Specification |

|---|---|

| Nominal Diameter (DN) | DN10 – DN600 (customizable for special specifications) |

| Nominal Pressure (PN) | PN10 – PN320; Class 150 – Class 1500 |

| Working Temperature Range | -60°C – 550°C

(Flexible seal: -60°C–200°C; Metal seal: -40°C–550°C) |

| Applicable Medium | Water, oil, natural gas, steam, weakly corrosive liquids/gases, acid-base solutions, organic solvents, etc. |

| Valve Body Material | Carbon steel (WCB), Stainless steel (304/316/316L), Alloy steel (WC6/WC9), Hastelloy (optional for strong corrosion) |

| Plug/Valve Seat Material | Plug: Stainless steel (304/316/316L), Alloy steel; Valve seat: Flexible seal (PTFE/EPDM/FKM), Metal seal (304/316/alloy steel) |

| Actuator Type | Pneumatic double-acting actuator, Pneumatic single-acting actuator (spring return) |

| Actuator Air Supply Pressure | 0.4 – 0.8 MPa |

| Response Time | 1 – 4 seconds (varies by valve diameter and actuator model) |

| Leakage Rate | Flexible seal: ANSI Class VI (zero leakage); Metal seal: ANSI Class IV |

| Flow Characteristic | Linear, Equal percentage, Quick opening (optional) |

| Connection Type | Flange connection (GB/T, DIN, ANSI, JIS), Threaded connection (NPT/G), Welded connection (BW/SW) |

| Control Signal (Optional) | 4–20 mA DC (with intelligent positioner for proportional control) |

| Actuator Protection Grade | IP65 (standard), IP67 (optional for outdoor/harsh environment) |

| Service Life | ≥ 80,000 cycles (normal working conditions) |

| Operation Mode | Automatic (pneumatic control), Manual emergency operation (optional handwheel) |

| Standards Compliance | Design: API 602, API 608, ISO 15761; Testing: API 598 |

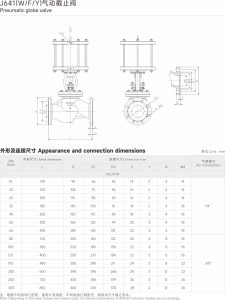

Ⅳ.The main shape and connection size