I. Product Introduction

The Pneumatic Gate Valve is a high-performance linear flow control device that integrates a rugged gate valve body with a reliable pneumatic actuator. It is widely applied in industrial pipeline systems for on-off control and throttling of various media, including water, oil, natural gas, steam, and weakly corrosive liquids and gases.

Designed for heavy-duty working conditions, this valve features a straight-through channel structure that minimizes flow resistance when fully open, ensuring unobstructed medium passage and low energy loss. The pneumatic actuator drives the gate plate to move vertically along the valve seat, achieving precise opening and closing operations. It is an essential component in industries such as petroleum, chemical engineering, power generation, water treatment, and metallurgy, providing stable, automated, and efficient flow control solutions. Whether in high-pressure pipeline systems or large-diameter fluid transportation projects, the pneumatic gate valve delivers excellent sealing performance and operational reliability, meeting the strict requirements of industrial process control.

II. Product Features

-

High-Efficiency Pneumatic ActuationEquipped with a high-thrust pneumatic actuator (double-acting or single-acting spring return type), the valve realizes rapid opening and closing with a response time of 2–5 seconds (depending on valve size). The single-acting actuator offers fail-safe protection: in case of air supply failure, it automatically drives the gate plate to the preset open or closed position via spring force, effectively preventing system accidents and enhancing operational safety.

-

Superior Sealing PerformanceAdopts a flexible or rigid sealing structure tailored to different working conditions. Flexible sealing uses elastic materials (e.g., PTFE, EPDM) embedded in the valve seat, ensuring zero leakage when the valve is closed, suitable for medium with strict sealing requirements. Rigid metal sealing (stainless steel seat and gate plate) provides excellent wear resistance and high-temperature resistance, suitable for high-pressure, high-temperature, and abrasive media scenarios. The sealing surface undergoes precision grinding and lapping, ensuring long-term sealing reliability and low maintenance frequency.

-

Durable and Corrosion-Resistant StructureThe valve body and gate plate are made of high-quality materials, including carbon steel (WCB), stainless steel (304/316/316L), and alloy steel, which can be selected according to the medium properties and working pressure. The inner and outer surfaces of the valve body are treated with anti-corrosion coating (e.g., epoxy resin coating) for applications in corrosive environments, effectively extending the service life of the valve. The overall structure is robust and pressure-resistant, capable of withstanding harsh working conditions such as high pressure, high temperature, and frequent operation.

-

Easy Installation and MaintenanceFeatures a compact and standardized design, with flange connection as the mainstream connection mode, compatible with national and international standards (GB, DIN, ANSI, JIS), facilitating quick integration into various pipeline systems. The split-type actuator and valve body connection structure allows for easy disassembly and maintenance without removing the entire valve from the pipeline. The pneumatic actuator is equipped with NAMUR standard interfaces, enabling seamless connection with solenoid valves, positioners, limit switches, and other auxiliary components to achieve remote control and status monitoring.

-

Wide Application AdaptabilitySuitable for on-off control of various media, including clean water, sewage, oil products, natural gas, steam, and weakly corrosive media. It covers a wide range of nominal diameters (DN15–DN1200) and nominal pressures (PN10–PN160, Class 150–Class 900), meeting the needs of small-diameter instrumentation pipelines and large-diameter industrial transmission pipelines. The valve can operate stably in the temperature range of -40°C to 600°C, adapting to different industrial process requirements.

III. Technical Data

| Technical Parameter | Specification |

|---|---|

| Nominal Diameter (DN) | DN15 – DN1200 (customizable for special requirements) |

| Nominal Pressure (PN) | PN10 – PN160; Class 150 – Class 900 |

| Working Temperature Range | -40°C – 600°C

(Flexible seal: -40°C–180°C; Metal seal: -40°C–600°C) |

| Applicable Medium | Water, oil, natural gas, steam, weakly corrosive liquids/gases, etc. |

| Valve Body Material | Carbon steel (WCB), Stainless steel (304/316/316L), Alloy steel (WC6/WC9) |

| Gate Plate Material | Stainless steel (304/316/316L), Alloy steel, Carbon steel with anti-corrosion coating |

| Seal Material | Flexible seal: PTFE, EPDM, Fluororubber (FKM)

Rigid seal: Stainless steel (304/316) |

| Actuator Type | Pneumatic double-acting actuator, Pneumatic single-acting actuator (spring return) |

| Actuator Air Supply Pressure | 0.4 – 0.8 MPa |

| Response Time | 2 – 5 seconds (varies by valve size and actuator model) |

| Leakage Rate | Flexible seal: ANSI Class VI (zero leakage)

Metal seal: ANSI Class IV |

| Connection Type | Flange connection (GB/T, DIN, ANSI, JIS), Welded connection (BW/SW) |

| Control Signal (Optional) | 4–20 mA DC (with positioner for proportional control) |

| Actuator Protection Grade | IP65 (standard), IP67 (optional for outdoor use) |

| Service Life | ≥ 50,000 cycles (normal working conditions) |

| Operation Mode | Automatic (pneumatic control), Manual (optional handwheel for emergency operation) |

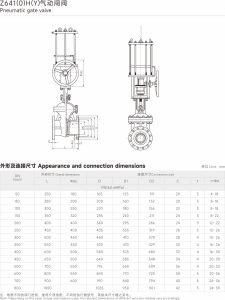

Ⅳ.The main shape and connection size