I. Product Introduction

The Pneumatic Ventilation Butterfly Valve is a specialized flow control device widely utilized in industrial ventilation systems, air conditioning (HVAC) systems, dust removal equipment, and flue gas treatment pipelines. It integrates a high-performance pneumatic actuator with a precision-engineered butterfly valve body, enabling rapid and reliable opening, closing, and flow regulation of gas media such as air, flue gas, and dust-laden air.

Designed primarily for ventilation and air volume control scenarios, this valve features a simple yet robust structure, ensuring stable operation even in harsh industrial environments with high temperatures, high humidity, or particulate matter. It serves as a critical component in optimizing system airflow, reducing energy consumption, and maintaining indoor or process air quality. Whether in power plants, steel mills, chemical factories, commercial buildings, or pharmaceutical facilities, the pneumatic ventilation butterfly valve provides efficient and automated flow control solutions tailored to diverse ventilation needs.

II. Product Features

-

Rapid and Responsive Actuation: Equipped with a high-torque pneumatic actuator, the valve achieves quick opening and closing (typical response time: 0.5–3 seconds), ensuring timely adjustment to changes in ventilation system requirements. The actuator supports both single-acting (spring return) and double-acting configurations, with single-acting models providing fail-safe protection (automatically returning to a preset position such as open or closed) in case of air supply failure, enhancing system safety and reliability.

-

Excellent Flow Control Performance: The valve adopts a streamlined butterfly plate design with a large flow area, minimizing airflow resistance and pressure loss (pressure loss coefficient ≤ 0.2). It offers precise linear flow regulation over a wide range (0–100% flow adjustment), allowing for accurate control of air volume and ensuring stable operation of the ventilation system. The butterfly plate and valve seat are designed with optimal sealing performance, effectively preventing air leakage (leakage rate ≤ 1% of nominal flow) and improving energy efficiency.

-

Durable and Corrosion-Resistant Construction: The valve body is available in materials such as carbon steel, stainless steel (304/316), and aluminum alloy, selected based on the working medium and environment. The butterfly plate is made of wear-resistant and corrosion-resistant materials (e.g., stainless steel with ceramic coating for dust-laden air applications), ensuring long service life even in harsh conditions. The valve seat adopts high-temperature resistant, aging-resistant elastomers (e.g., EPDM, silicone rubber) or metal seals, adapting to working temperatures ranging from -40°C to 400°C.

-

Easy Installation and Maintenance: The valve features a compact and lightweight design, facilitating easy installation in various pipeline layouts (flange connection, wafer connection, or lug connection). The split-type structure allows for convenient disassembly and maintenance without removing the entire valve from the pipeline, reducing downtime and maintenance costs. Additionally, the pneumatic actuator is equipped with standard interfaces (e.g., NAMUR standard), enabling easy integration with solenoid valves, positioners, and other control components for automated control systems.

-

Wide Application Adaptability: Suitable for handling a variety of gas media, including clean air, dust-laden air, flue gas, and weakly corrosive gases. It can be used in both positive pressure and negative pressure ventilation systems, with nominal diameters ranging from DN50 to DN2000, meeting the needs of small to large-scale ventilation projects. The valve also complies with international standards (e.g., ISO, DIN, ANSI), ensuring compatibility with global pipeline systems.

III. Technical Data

|

Technical Parameter

|

Specification

|

|---|---|

|

Nominal Diameter (DN)

|

DN50 – DN2000 (customizable for special requirements)

|

|

Nominal Pressure (PN)

|

PN0.1 – PN1.6 MPa

|

|

Working Temperature Range

|

-40°C – 400°C (varies by seal material: EPDM: -40°C–150°C; Silicone rubber: -20°C–250°C; Metal seal: -40°C–400°C)

|

|

Medium

|

Clean air, dust-laden air, flue gas, weakly corrosive gases, etc.

|

|

Valve Body Material

|

Carbon steel (WCB), Stainless steel (304/316), Aluminum alloy

|

|

Butterfly Plate Material

|

Stainless steel (304/316), Carbon steel with anti-corrosion coating, Stainless steel with ceramic coating

|

|

Seal Material

|

EPDM, Silicone rubber, Fluororubber (FKM), Metal seal (304/316)

|

|

Actuator Type

|

Pneumatic double-acting actuator, Pneumatic single-acting actuator (spring return)

|

|

Air Supply Pressure for Actuator

|

0.4 – 0.6 MPa

|

|

Response Time

|

0.5 – 3 seconds (depending on valve size and actuator type)

|

|

Leakage Rate

|

≤ 1% of nominal flow (elastomer seal); ≤ 3% of nominal flow (metal seal)

|

|

Connection Type

|

Wafer type, Lug type, Flange type (PN1.0/1.6 MPa, compatible with GB, DIN, ANSI flanges)

|

|

Control Signal (Optional)

|

4–20 mA (with positioner for proportional control)

|

|

Protection Grade

|

IP54 – IP65 (actuator)

|

|

Service Life

|

≥ 100,000 cycles (normal working conditions)

|

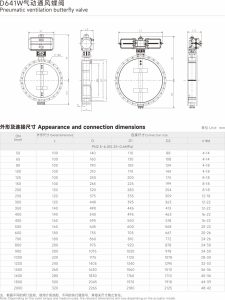

四.The main shape and connection size